Novel miniature waste processor

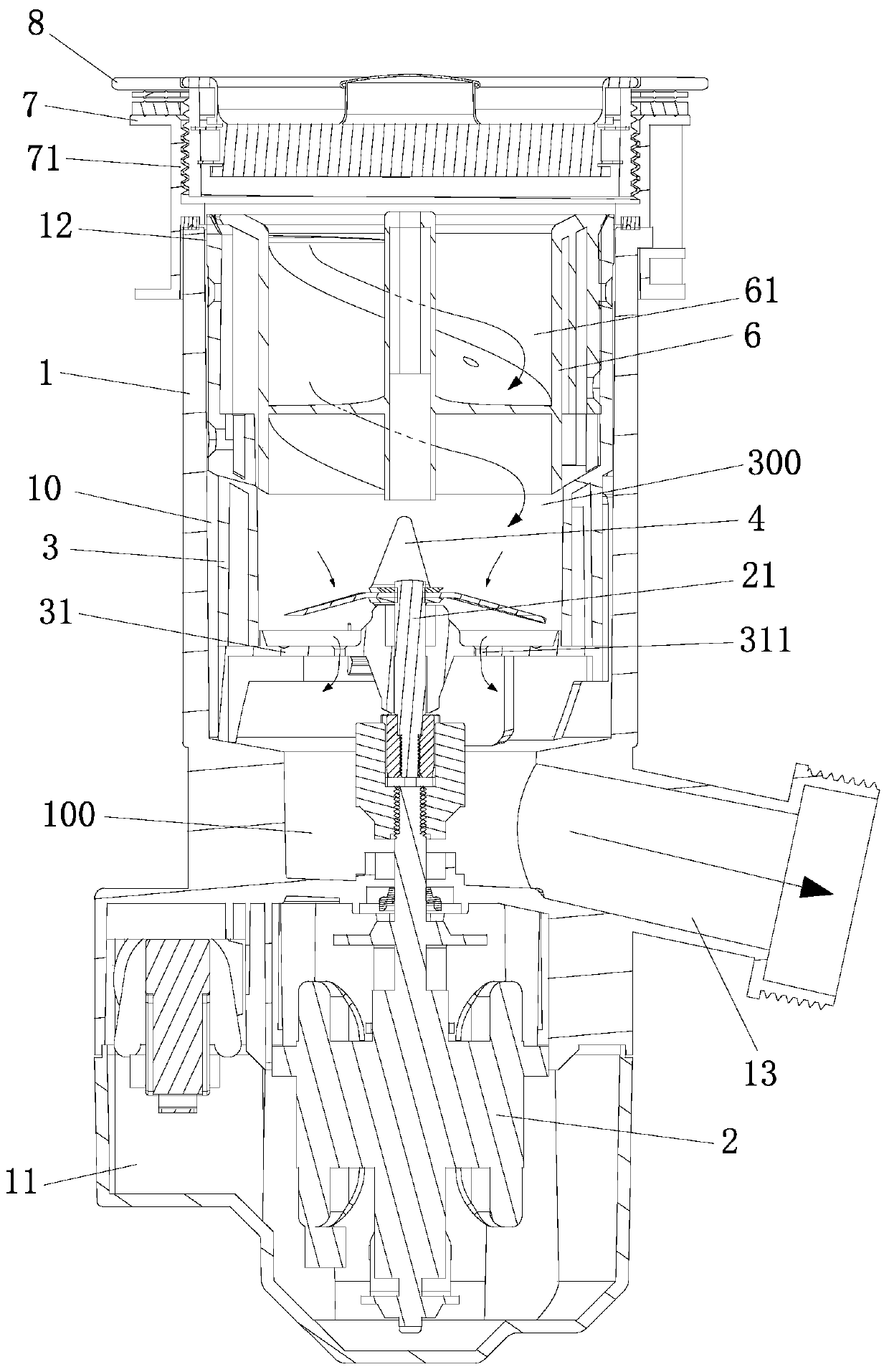

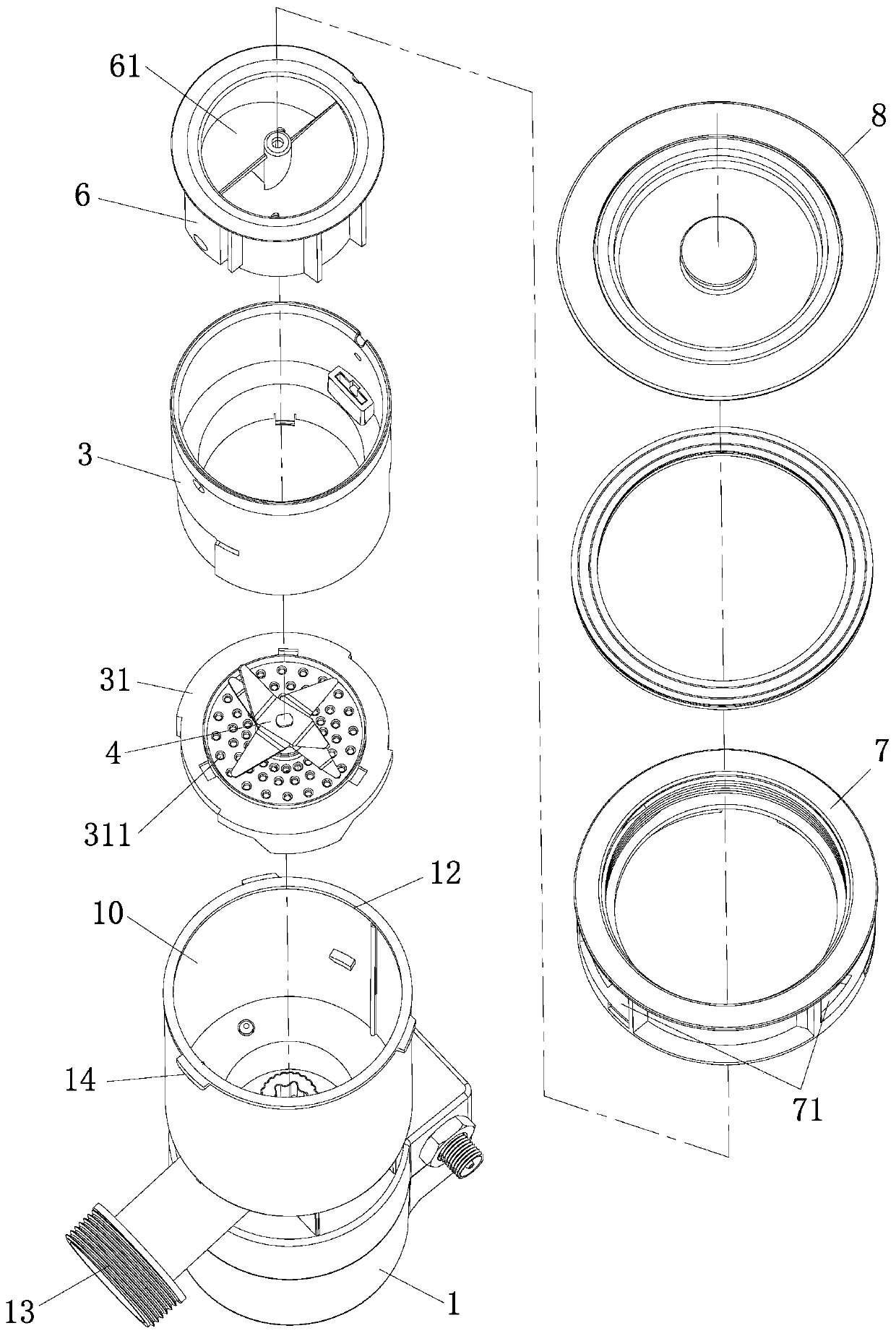

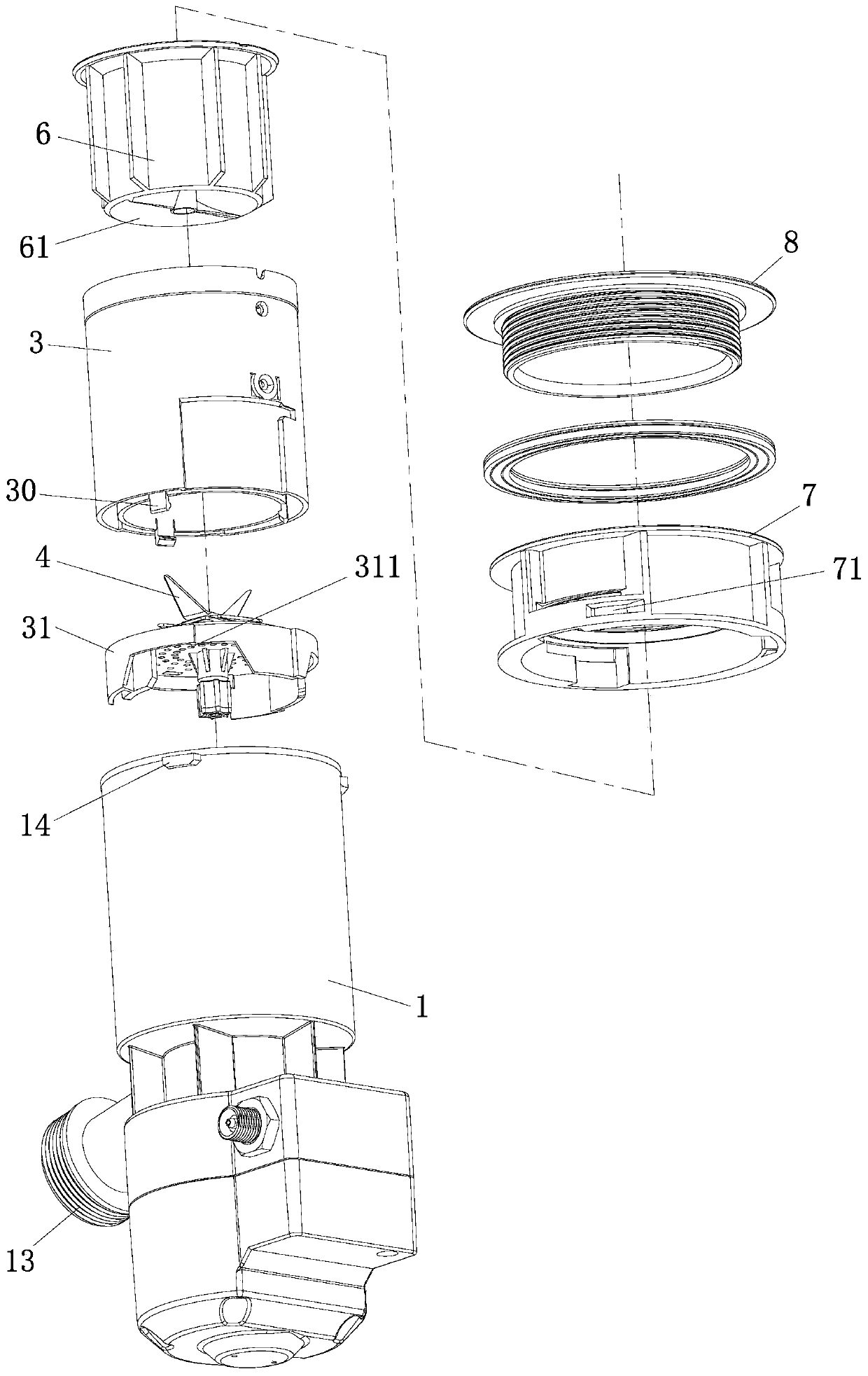

A technology for garbage disposal and garbage disposal, which is applied in grain processing, indoor sanitary pipe installations, water supply installations, etc., and can solve the problems of inability to achieve pulverization, high noise and vibration, and easy entanglement of flexible garbage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

[0031] see Figure 4-Figure 5 The main difference between the new type of micro-garbage disposer and the first embodiment is that the blocking mechanism includes a straight-through ring 51 and a diversion cone 52, and the middle part of the straight-through ring 51 is provided with a straight-through hole (for kitchen waste and kitchen waste). The entry of remaining garbage), which is installed on the upper part of the knife cage 3 and is close to the feed port 12. The guide cone 52 is an inverted cone, which is installed in the middle or lower part of the knife cage 3 and is located at the center of the mixing tool 4. above. The straight-through hole is located on the upper part of the knife cage, and the guide cone 52 is located on the middle and lower parts of the knife cage. The objects entering from the through-hole will be scattered around through the guide cone 52, which can effectively avoid the insertion of human hands, and can also realize The transportation of kitc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com