Circulating cleaning machine for electromechanical equipment parts

A technology for electromechanical equipment and parts, which is applied in the field of circular cleaning machines for electromechanical equipment parts, can solve the problems of reducing the clearance of helical gears and the cleaning effect of the upper surface, and achieve the effect of improving the cleaning effect and preventing reoccurrence of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

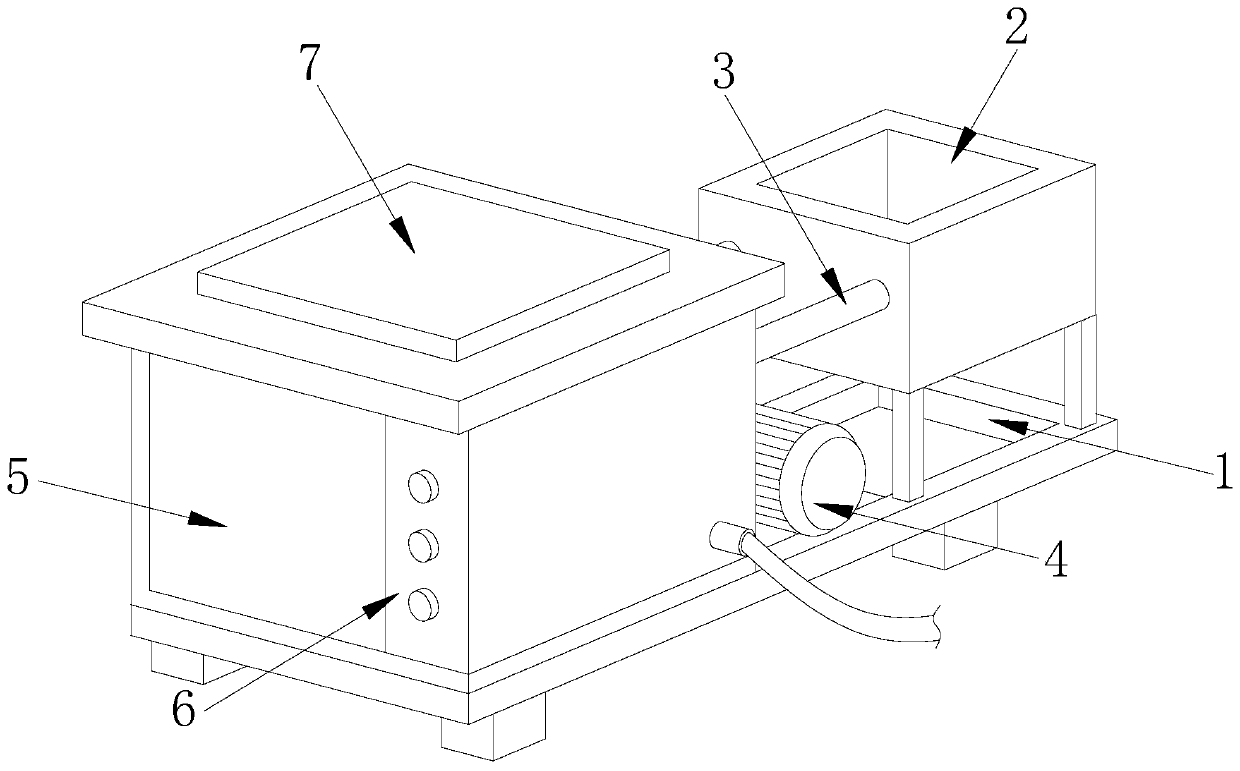

[0022] as attached figure 1 to attach Figure 5 Shown:

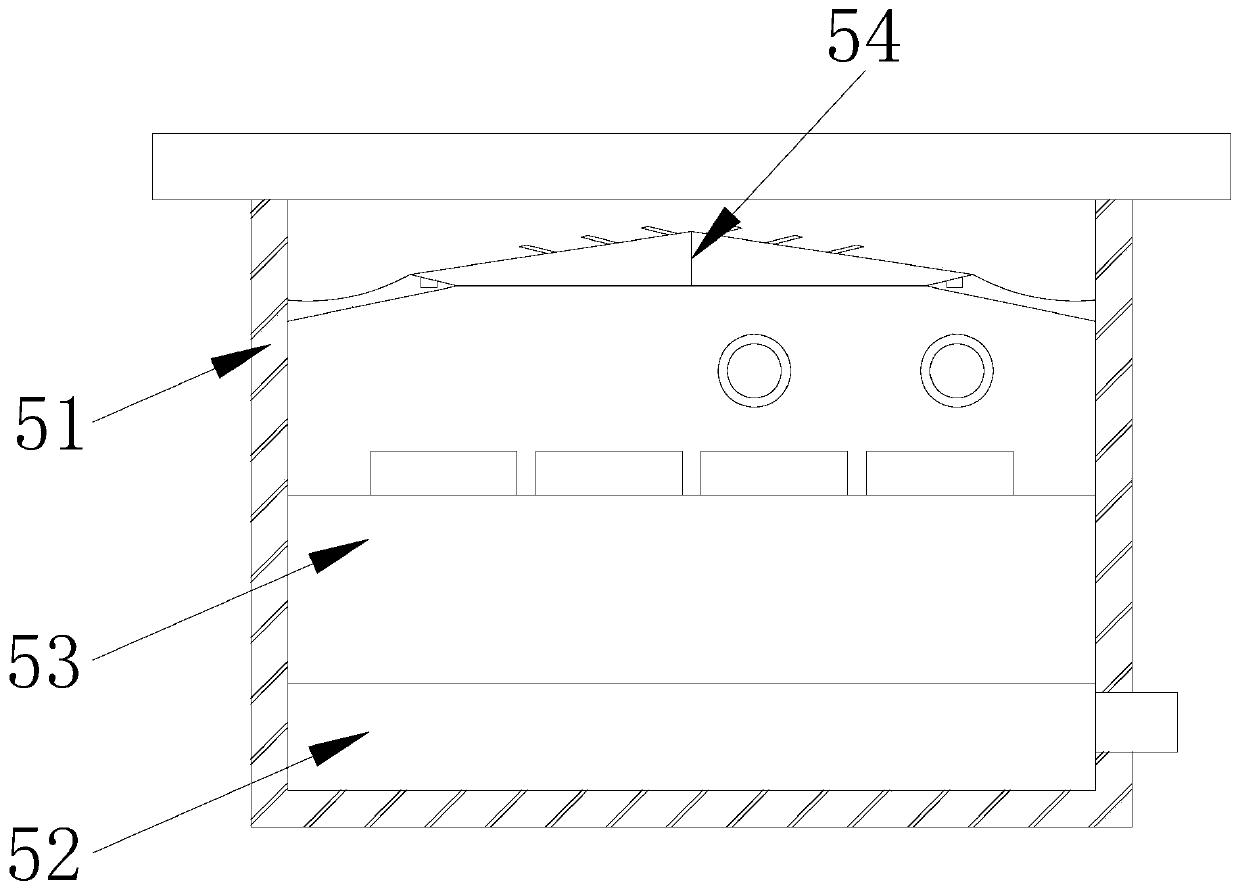

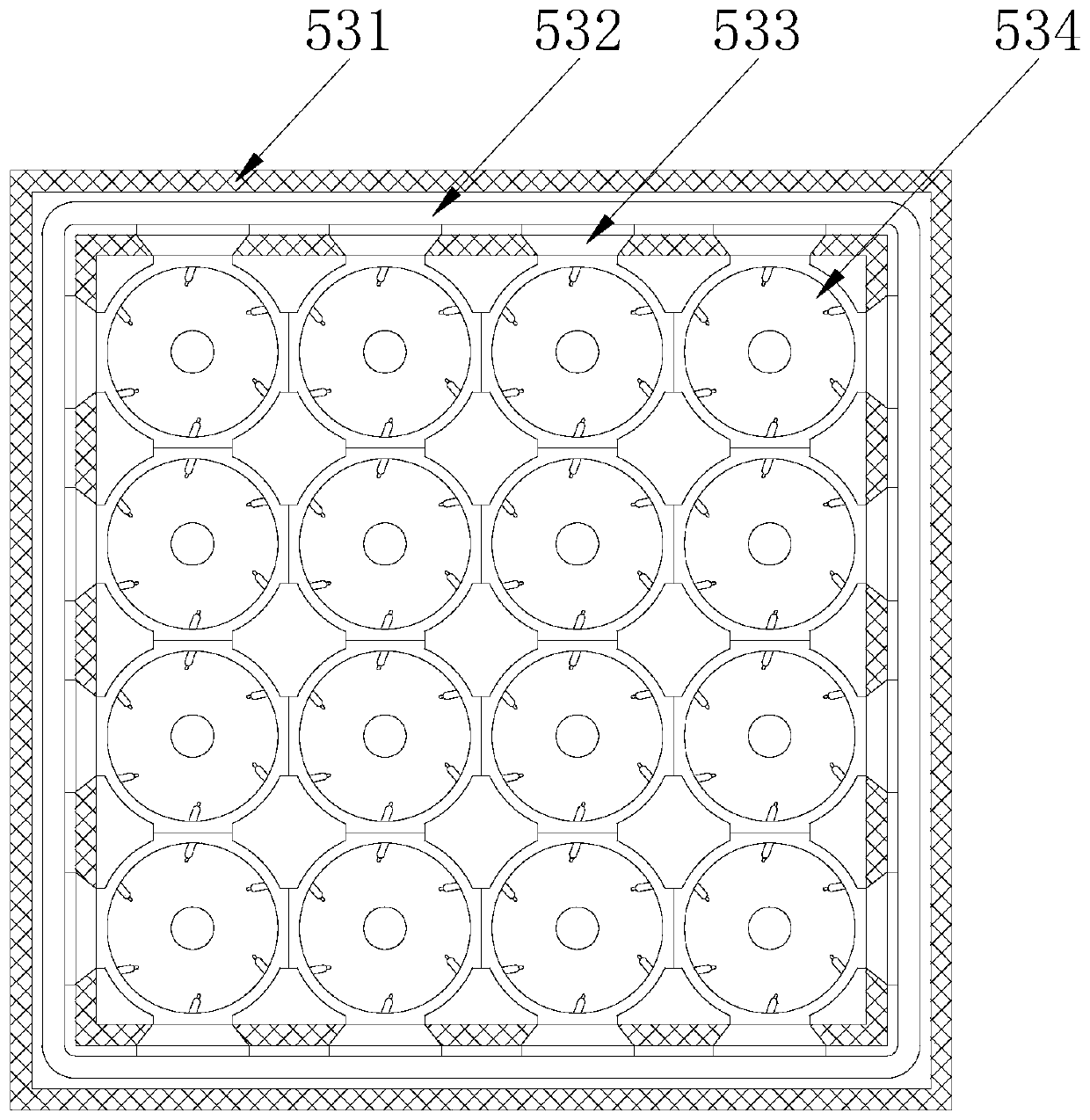

[0023] The present invention is a cycle cleaning machine for mechanical and electrical equipment parts, its structure includes a support frame 1, a water tank 2, a water inlet pipe 3, a water pump 4, a cleaning tank 5, a control panel 6, a top cover 7, the rear end of the support frame 1 and the water tank 2. The lower ends are welded together. The water tank 2 is connected to the cleaning tank 5 through the water inlet pipe 3. The water inlet pipe 3 is connected to the water pump 4. The front surface of the cleaning tank 5 is embedded with a control panel 6, and the top of the cleaning tank 5 is provided with a There is a top cover 7, and the cleaning box 5 includes a box body 51, a high-pressure injection box 52, a placement groove 53, and a top layer separation mechanism 54. A high-pressure injection box 52 is fixedly installed at the bottom of the inner side of the box body 51. The upper end is provided with a plac...

Embodiment 2

[0030] as attached Figure 6 to attach Figure 7 Shown:

[0031] Wherein, the top separation mechanism 54 includes an adhesive plate 541, a card slot 542, a locking rod 543, and a separation diffusion plate 544. There is a slot 542, and the locking rod 543 is installed inside the slot 542 by clearance fit. The locking rod 543 is fixedly installed on the lower left side of the separation diffusion plate 544. There are two adhesive plates 541, and The upper end is provided with a concave curved surface, which is respectively arranged inside the left and right sides of the box body 51, which is beneficial for adhering and placing the oil stains flowing on both sides of the upper layer.

[0032] Wherein, the separation and diffusion plate 544 includes a plate body 44a, a contact frame 44b, a flow port 44c, and a shielding plate 44d. The bottom of the body 44a, the flow port 44c runs through the inside of the plate body 44a, the baffle plate 44d is fixedly installed on the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com