A negative pressure thermal desorption treatment system for mercury-contaminated soil

A treatment system, thermal desorption technology, applied in the field of negative pressure thermal desorption treatment system, can solve problems such as secondary pollution, easy air leakage, soil nutrient damage, etc., to improve heating efficiency and prevent compaction and agglomeration , the effect of increasing the initial temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0022] Referring to the accompanying drawings, the specific implementation is as follows:

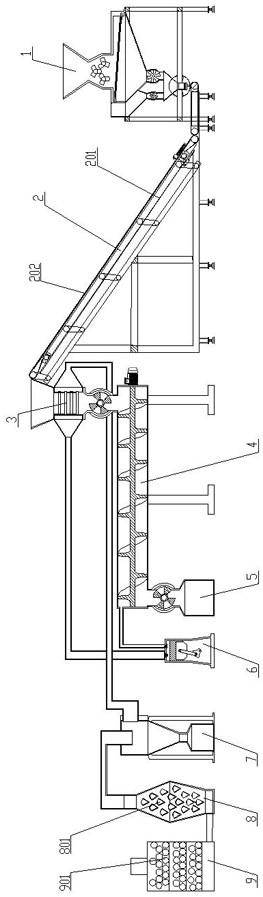

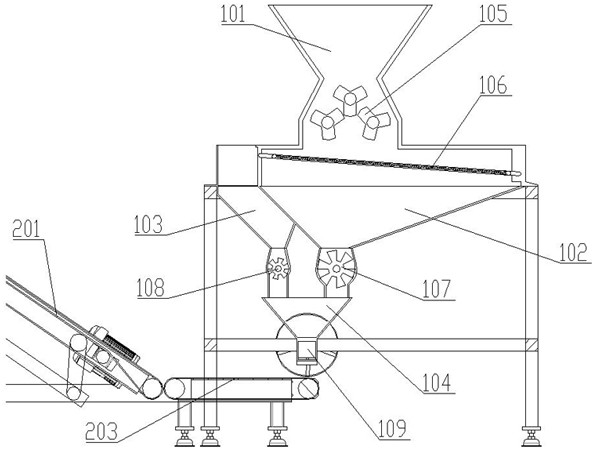

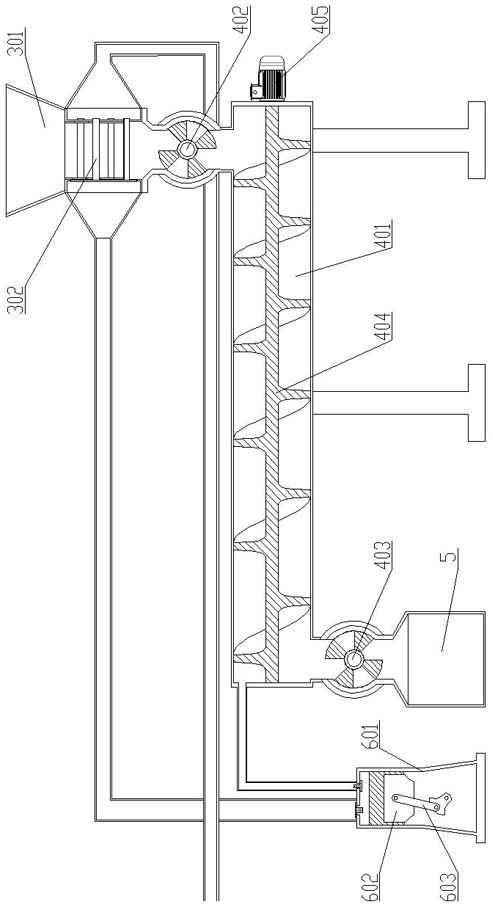

[0023] Such as figure 1 As shown, a negative pressure thermal desorption treatment system for mercury-contaminated soil includes a pretreatment device 1, a feeding device 2, a waste heat utilization heat exchanger 3, a negative pressure heating device 4, a soil collection box 5 and an air extraction Device 6: the pretreatment device 1 crushes the soil and mixes the soil with the catalyst, the feeding device 2 transports the soil from the pretreatment device 1 to the waste heat utilization heat exchanger 3, and the waste heat utilization heat exchanger 3 preheats the soil and The soil is dropped to the negative pressure heating device 4, the negative pressure heating device 4 performs heat desorption treatment on the soil and the soil is dropped to the soil collection box 5, and the air extraction device 6 extracts the hot gas inside the negative pressure heating device 4 to make the neg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com