Organic solid waste composting aeration system

An aeration system and organic solid technology, which is applied in the field of compost aeration system, can solve the problems of impact constraints, large aeration volume, and large floor space, so as to eliminate mutual influence constraints, improve composting efficiency, and reduce floor space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

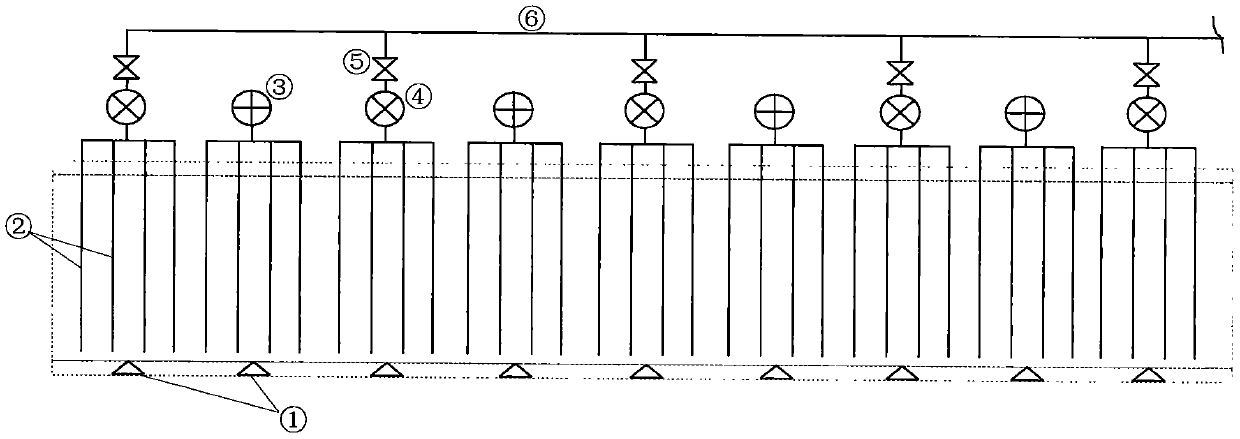

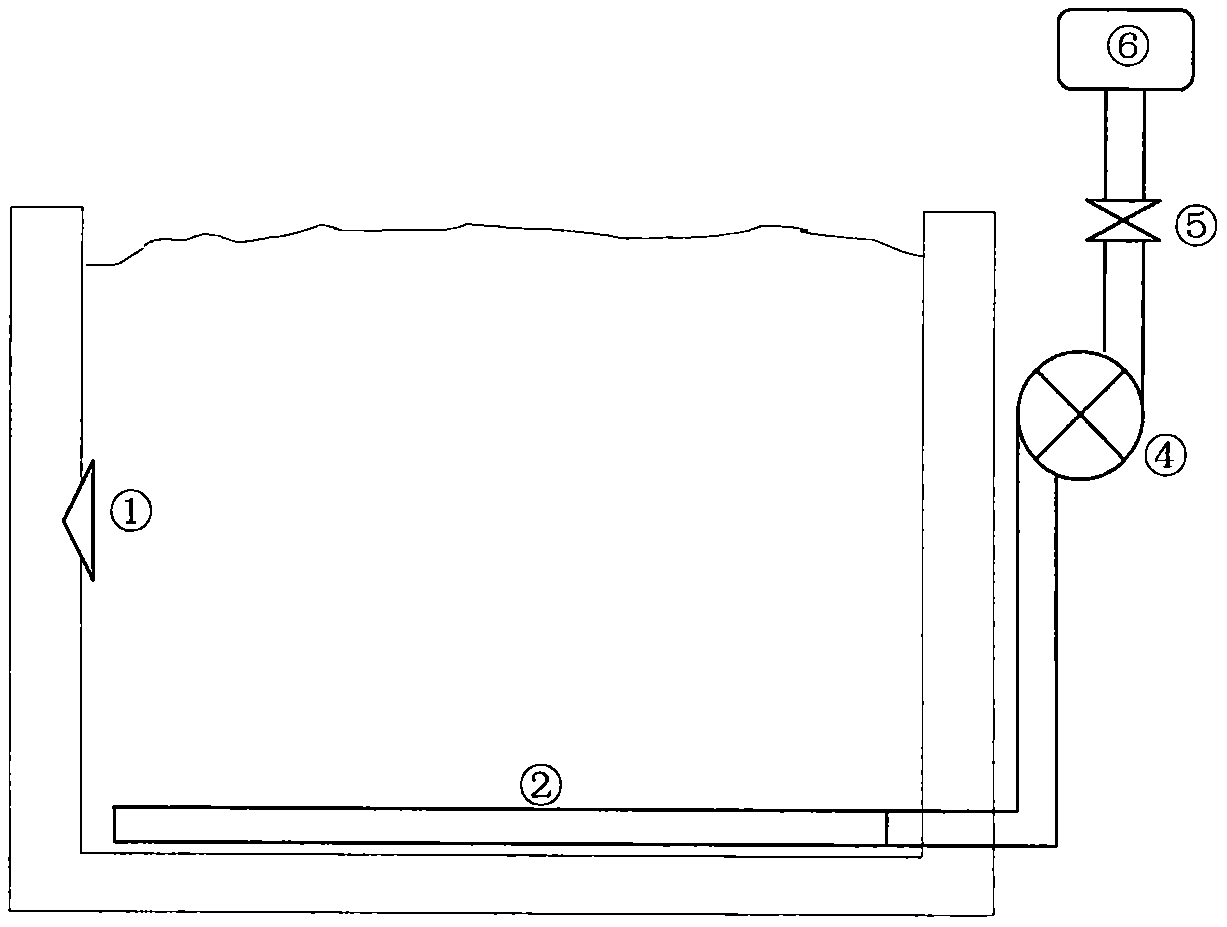

[0017] The construction and operation process of a kind of organic solid waste composting aeration system of the present invention is further illustrated in conjunction with accompanying drawings as follows:

[0018] (1) Construction stage

[0019] Build a compost fermentation bin, divide the fermentation bin into 9 sections according to the number of turning times in a fermentation cycle and the capacity of the turning equipment; temperature sensors are buried in the material contact range of the 9 section walls, and a total of 9 temperature sensors are installed; 9 section bottoms Perforated aeration pipes are laid at each position, and a total of 9 groups of perforated aeration pipes are set; each group of perforated aeration pipes is collected into a blower or induced draft fan, and a total of 4 blowers and 5 induced draft fans are installed; the air volume of the induced draft fan is greater than that of the adjacent blower The air volume is 10-100%; the air outlet of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com