Membrane column out-of-orbit monitoring system and method for DTRO equipment

A monitoring system and membrane column technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of membrane column running circle efficiency and low accuracy, and achieve the effect of avoiding errors and work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The present invention is based on the high interception rate of monovalent salt by the DTRO diaphragm, and the characteristics that the conductivity is proportional to the salt content. , the ratio between the first conductivity at the water inlet of the membrane column 11 and the second conductivity at the outlet of the clear liquid will increase. Therefore, the first conductivity at the water inlet of the membrane column 11 and the clear water can be calculated and The ratio between the second conductivities at the outlet of the liquid is used to judge whether the membrane column 11 is lapping.

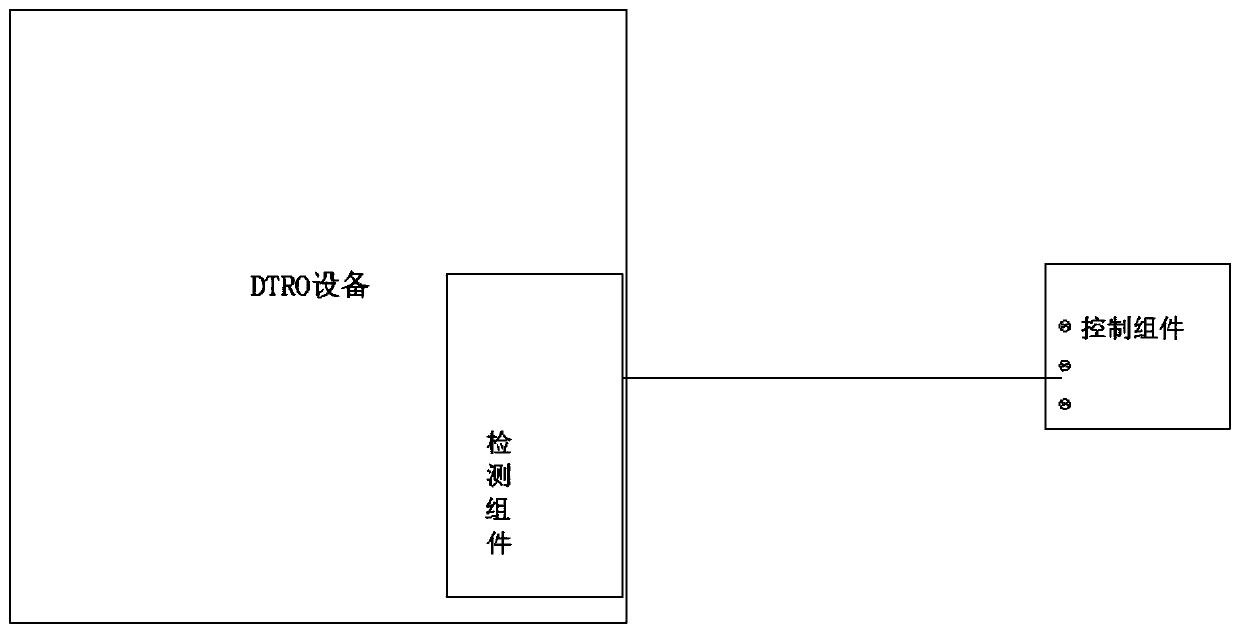

[0040] Such as figure 1 As shown, the present invention discloses a membrane column running circle monitoring system for DTRO equipment, including: a monitoring component arranged on the DTRO equipment and a control component connected to the monitoring component;

[0041] The monitoring component is used to monitor in real time the first conductivity of the stock solution i...

Embodiment 2

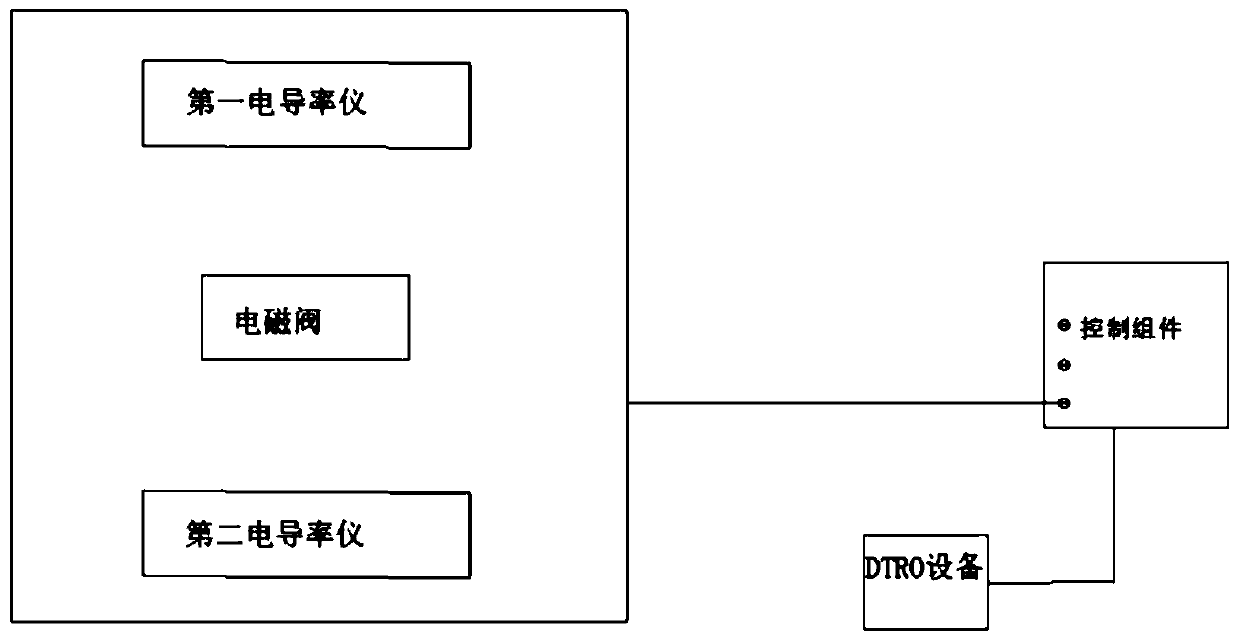

[0045] Embodiment 2 is a preferred embodiment of Embodiment 1. It differs from Embodiment 1 in that it expands the structure and functions of the membrane column lap monitoring system of DTRO equipment:

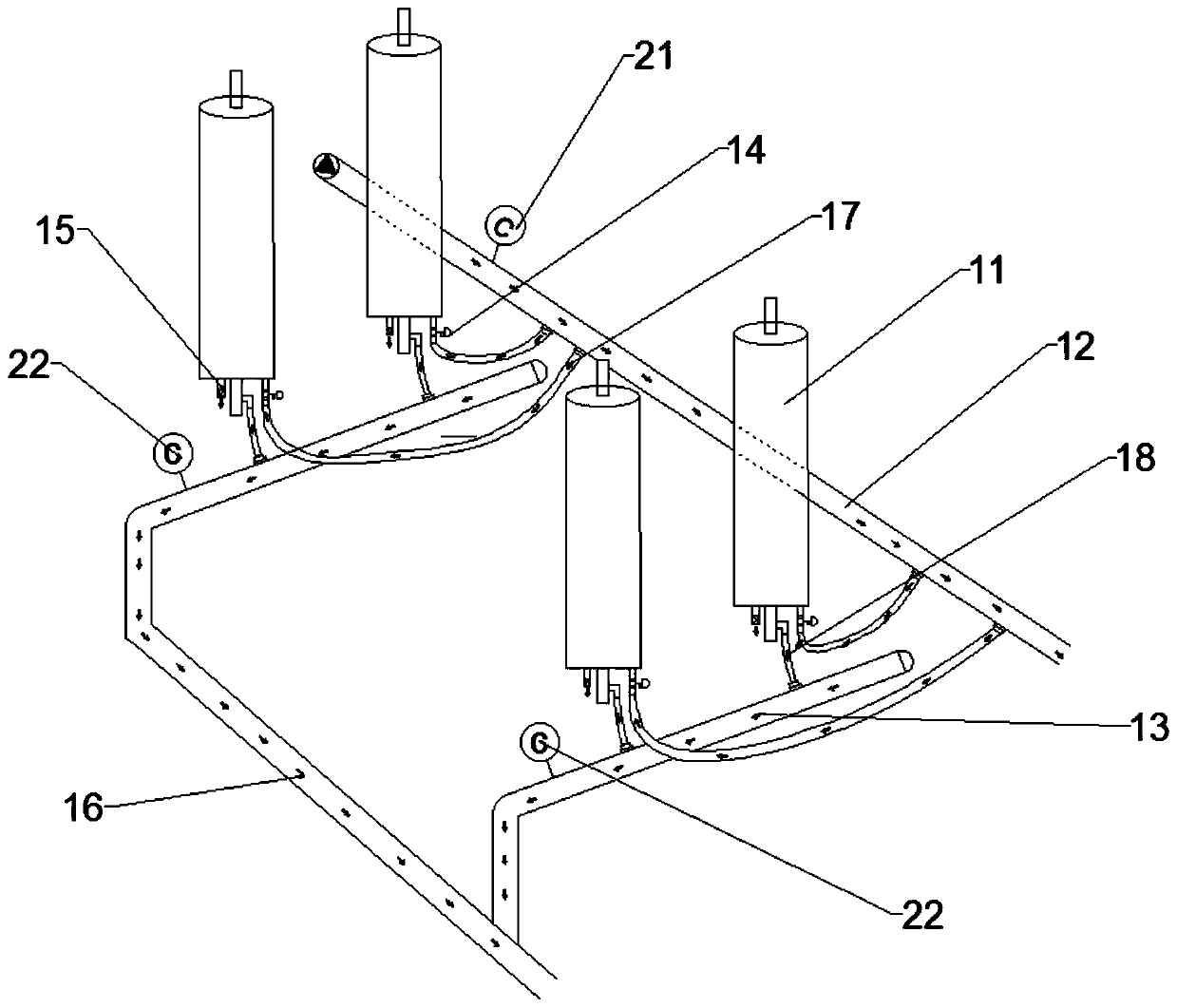

[0046] Such as figure 2 and image 3 As shown, the DTRO equipment monitored by the membrane column lap monitoring system in this embodiment includes a water inlet pipe 12 , a plurality of water inlet branch pipes, a plurality of membrane column units and a plurality of clear liquid outlet pipes 13 . At least one membrane column 11 is arranged in the membrane column unit. In this embodiment, a plurality of membrane columns 11 are arranged in one membrane column unit, and the membrane column 11 is provided with a water inlet, a clear liquid outlet and a concentrated liquid outlet;

[0047] The water outlet of the water inlet pipe 12 is connected to the water inlet of a plurality of first hoses 17, and the water outlets of the plurality of first hoses 17 are connected to the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com