A manufacturing device for the production of weather-resistant and environmentally friendly anti-corrosion coatings

A technology for anti-corrosion paint and production device, which is applied in the direction of anti-corrosion paint, mixer with rotary stirring device, coating, etc., can solve the problems of reducing the processing efficiency of anti-corrosion paint, slow discharge, etc., to shorten the mixing time, ensure the effectiveness, The effect of accelerating mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

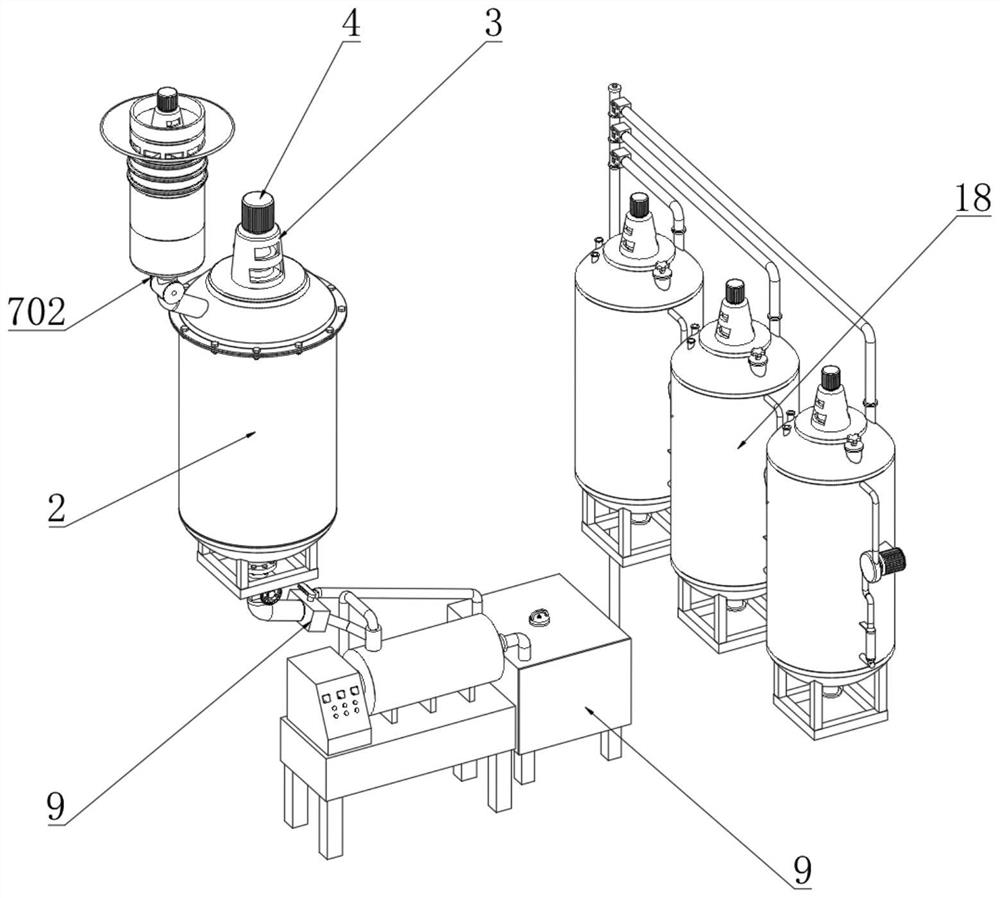

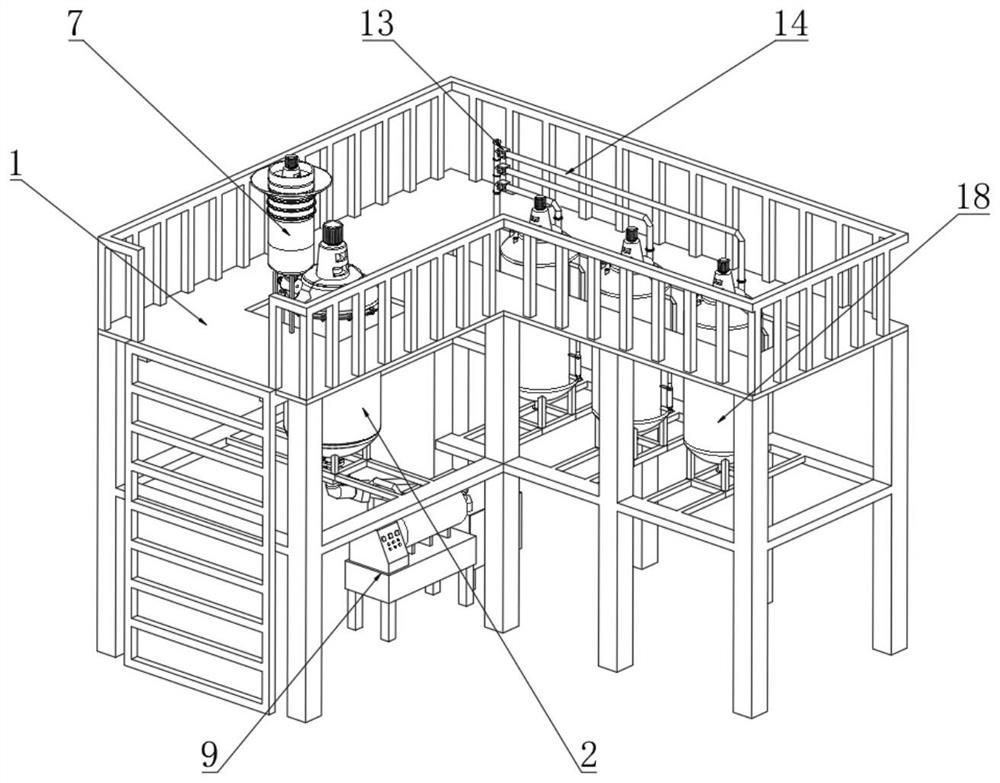

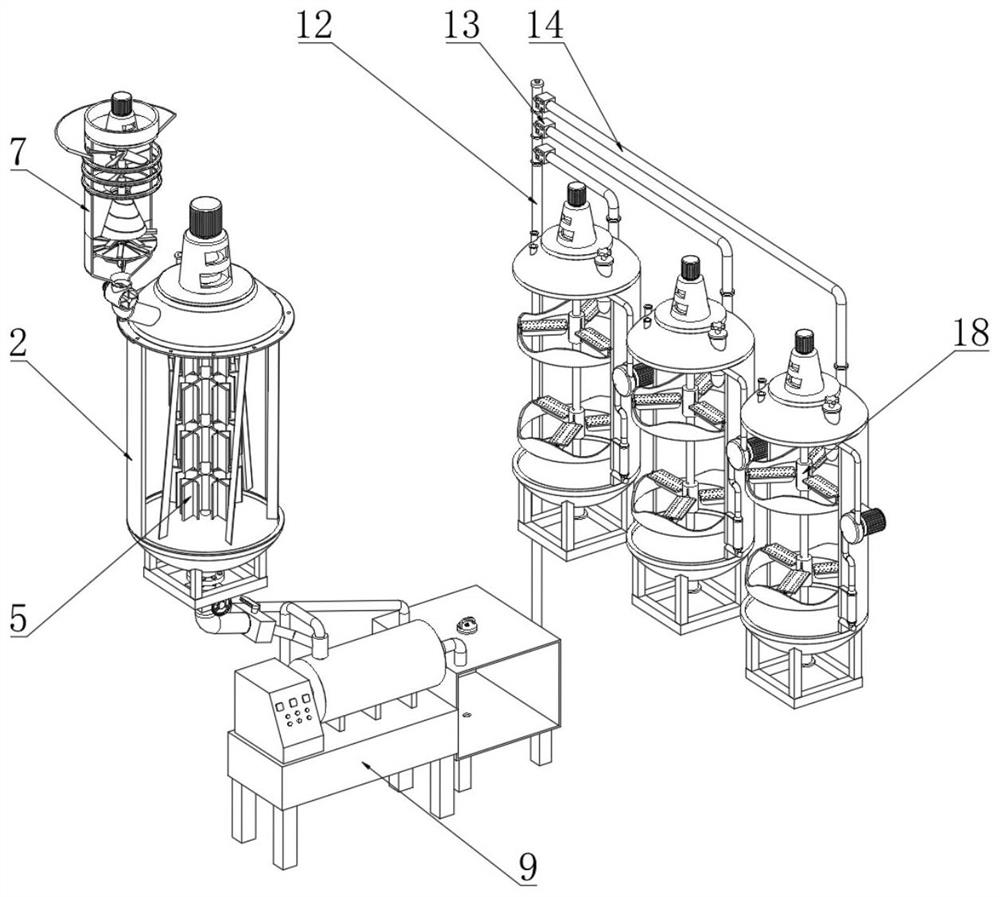

[0071] Example: as Figure 1-9 As shown in the figure, the present invention provides a technical solution, a production device for the production of weather-resistant and environmentally friendly anti-corrosion paint, comprising a mounting bracket 1, one end of the top of the mounting bracket 1 is fixedly connected with a dispersion barrel 2, and the middle of the top of the dispersion barrel 2 is fixedly connected with a fixed installation The frame 3, the middle of the top of the fixed mounting frame 3 is fixedly connected with a dispersing motor 4, the input end of the dispersing motor 4 is electrically connected with the output end of the mains, and the inside of the dispersing barrel 2 is provided with an efficient dispersing discharge mechanism 5;

[0072] The high-efficiency dispersing and discharging mechanism 5 includes an upper sealed round box 501, an installation round pipe 502, a lower sealed round box 503, a dispersing shaft 504, a driving gear 505, a fixing ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com