Self-cleaning pulverizer for processing high-quality heparin sodium

A self-cleaning technology of heparin sodium, which is applied in grain processing, etc., can solve the problems of drug pollution, high-quality heparin sodium drug pollution, and expensive materials, and achieve the effects of preventing material pollution, saving cleaning and putting time, and not easy to clog

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

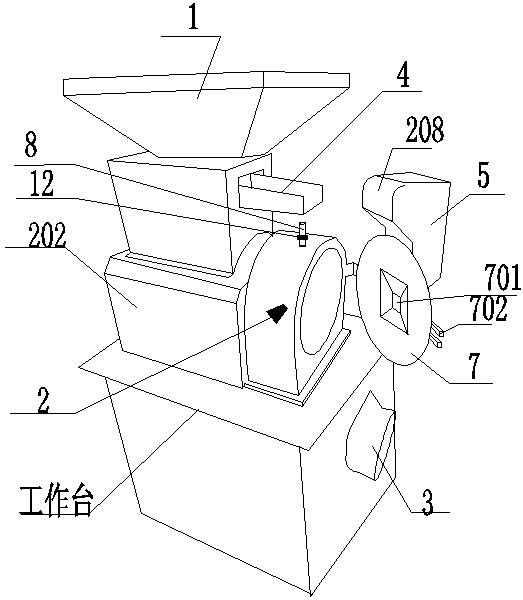

[0027] The invention relates to the technical field of material crushing, and discloses a self-cleaning pulverizer. After the pulverizer is shut down, an inert gas is sprayed through an air injection device to blow off the residual materials on the inner wall of the crushing mechanism cavity and on the screen to prevent the materials from being polluted. Miscellaneous pollution.

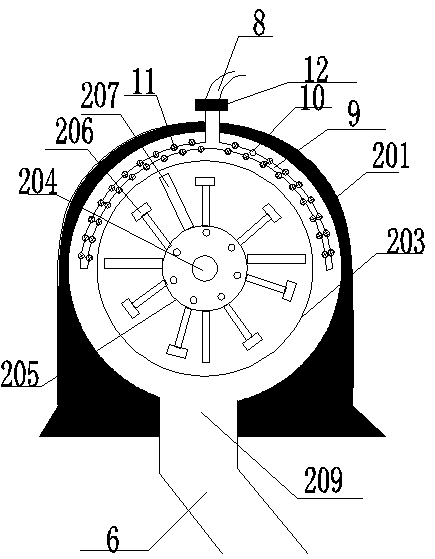

[0028] The pulverizer mainly includes a feed hopper 1 , a crushing mechanism 2 connected with the feed hopper 1 , and a total discharge port 3 connected with the discharge port of the crushing mechanism 2 . The inner wall of the cavity 201 of the crushing mechanism 2 is detachably fixed with a screen 203, and the inner wall of the cavity 201 of the crushing mechanism 2 is also provided with an air injection device. Exhaust sheet 9. In this embodiment, the intake pipe 8 is disposed through the cavity 201 and fixed on the cavity 201 . The exhaust sheet 9 is located between the screen 203 and the inne...

Embodiment approach 2

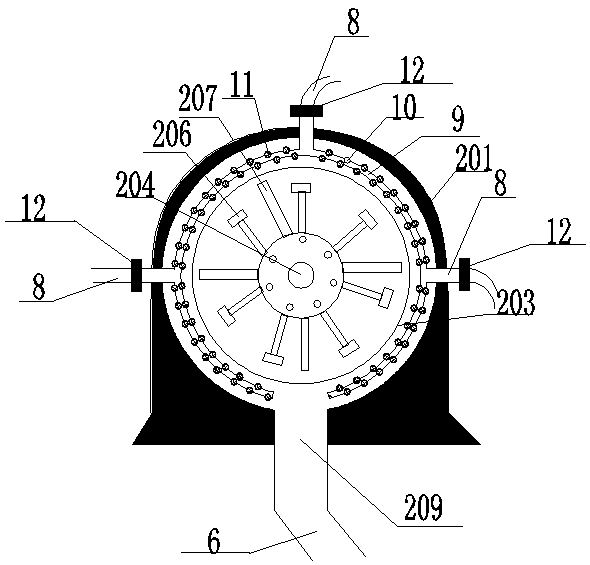

[0036]This embodiment is a further optimization of Embodiment 1. The specific optimization plan is: the exhaust sheet 9 is arranged along the circumferential direction of the screen 203, which is in a cylindrical structure, wraps the screen 203, and is discharged from the bottom of the crushing mechanism 2. There is a gap in the position facing the port 209, and there are multiple intake pipes 8 on the cavity 201 of the pulverizing mechanism 2 (three can be set in this embodiment), the intervals of which are fixed on the cavity 201 and penetrate through the cavity 201, communicating with the exhaust piece 9. The three air intake ducts 8 in this embodiment can be respectively located at the top and the left and right sides of the cavity, so that an exhaust sheet 9 is arranged between the inner wall of the cavity 201 and the screen 203, and the three air intake ducts 8 are filled into the air at the same time. Inert gas, so that the material cleaning efficiency is improved and d...

Embodiment approach 3

[0039] This embodiment is a further optimization of Embodiment 1 or Embodiment 2. The specific optimization plan is: a check valve 11 is also provided on each exhaust hole, and the inert gas can only be filled into the cavity 201 from the intake pipe 8 When the air is not sprayed, the one-way valve 11 is closed, and the material powder will not pass through the exhaust hole 10 and then be discharged through the air inlet pipe 8, so as to prevent material waste.

[0040] Other operations in this embodiment are the same as those in Embodiment 1 or Embodiment 2, and will not be repeated here.

[0041] working principle:

[0042] 1. Start the driving mechanism to make the pulverizer work, the material enters the pulverizing mechanism 2 through the feeding funnel 1, and is hammered by the hammer head 206 to realize the pulverization of the material.

[0043] 2. After the pulverizer stops, open the gas valve 12 and inject inert gas.

[0044] 3. Complete the self-cleaning of the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com