Multipurpose wall surface grinding machine

A grinding machine, multi-purpose technology, applied in machine tools suitable for grinding workpiece planes, grinding machine parts, grinding machines, etc., can solve problems such as single function, and achieve the effect of reducing wear and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

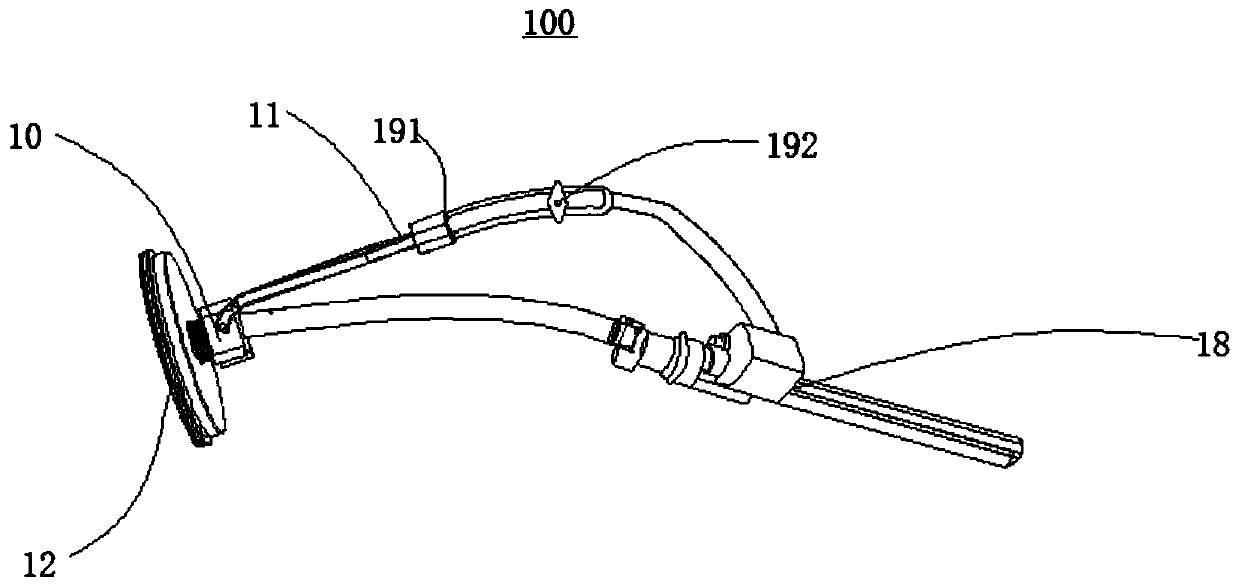

[0044] Please refer to figure 1 , figure 1 Shown is a schematic structural view of the multi-purpose wall sander 100 . This embodiment provides a multi-purpose wall grinder 100, which includes a function disc and a grinder body. The grinder body includes a transmission assembly 10, a support assembly 11 and a power assembly 18, the transmission assembly 10 includes a motor body 101 and a transmission shaft 102, the support assembly 11 and the transmission assembly 10 are connected to each other, and the power assembly 18 is configured to provide the transmission assembly 10 with power. The function disk is a disk-shaped structure, and the function disk is provided with a threaded hole, the threaded hole cooperates with the transmission shaft 102, and the function disk rotates along the axis of the thread hole through the transmission shaft 102. The multi-purpose wall grinder 100 can detachably connect the function disc and the grinder body by setting the function disc and t...

Embodiment 2

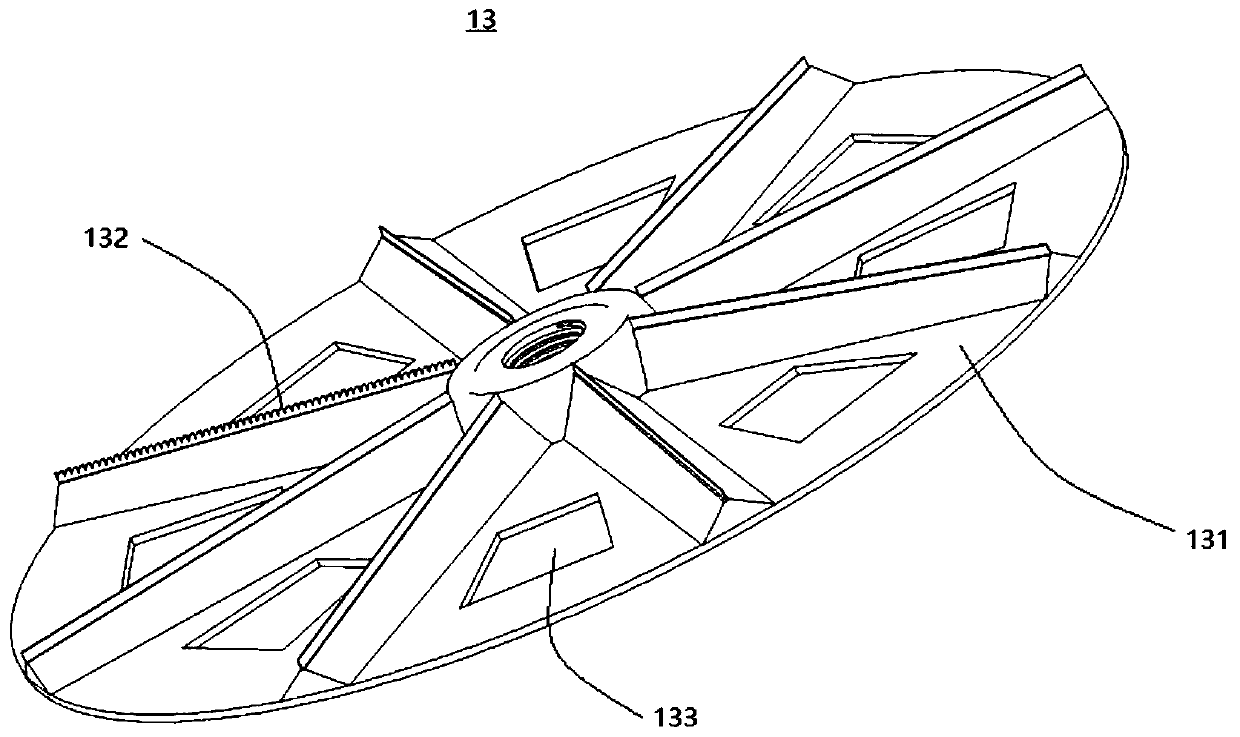

[0060] Please refer to Figure 4 , the present embodiment provides a multipurpose wall grinder 100, which includes a functional disc and a grinder body. The grinder body includes a transmission assembly 10 and a support assembly 11, the transmission assembly 10 includes a motor body 101 and a transmission shaft 102, and the support assembly 11 and the transmission assembly 10 are connected to each other. The function disk is a disk-shaped structure, and the function disk is provided with a threaded hole, the threaded hole cooperates with the transmission shaft 102, and the function disk rotates along the axis of the thread hole through the transmission shaft 102. The multi-purpose wall grinder 100 can detachably connect the function disc and the grinder body by setting the function disc and the grinder body, and the user can choose different function discs according to the specific use environment to realize the functions of grinding and planing walls Interactive, at the same...

Embodiment 3

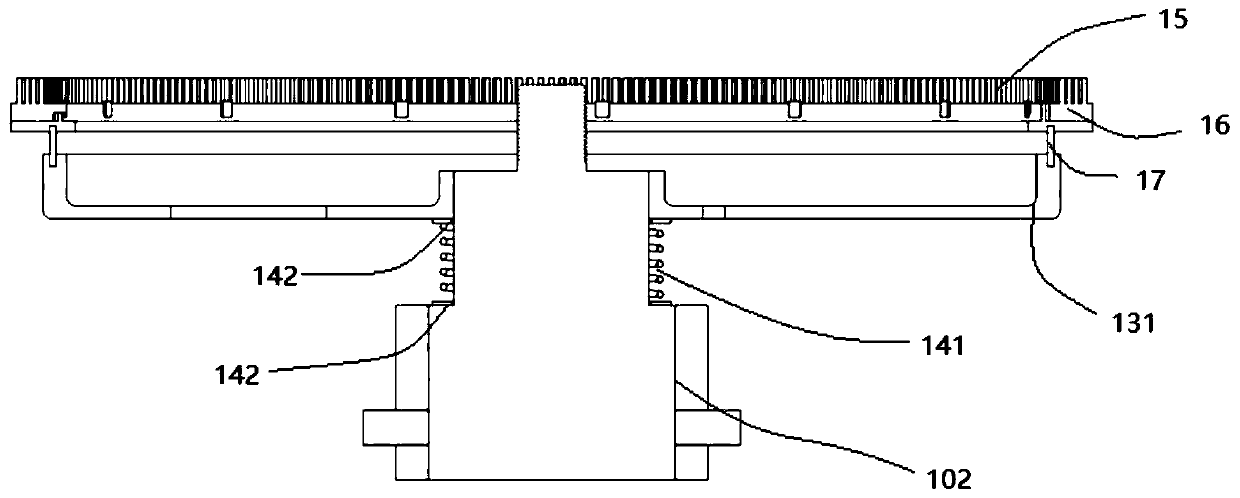

[0064] Please refer to Figure 5 , Figure 5 An exploded view of the multipurpose wall sander shown.

[0065] The grinder body also includes a hair brush 15, a fixed plate 16 and a connecting plate 17, the fixed plate 16 and the tray 131 are provided with corresponding draw-in grooves, the connecting plate 17 and the draw-in grooves are adapted to each other, and the connecting plate 17 is embedded in the draw-in grooves In order to make the fixed disk 16 and the tray 131 detachably connected, the brush 15 and the fixed disk 16 are connected to each other through buckles.

[0066] Please refer to Image 6 , Image 6 It is a structural schematic diagram of the support assembly 11.

[0067] The grinding machine body also includes a support assembly 11, the support assembly 11 includes a connecting frame 111, a telescopic rod 112 and a hoop structure 113, one end of the connecting frame 111 is connected to the transmission shaft 102 assembly, and the hoop structure 113 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com