A kind of aluminum alloy house and construction method thereof

A technology of aluminum alloy and houses, applied in the field of aluminum alloy houses and their construction, can solve the problems of low strength, inconvenient installation and disassembly, etc., and achieve the effect of high strength, stable overall structure, and convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

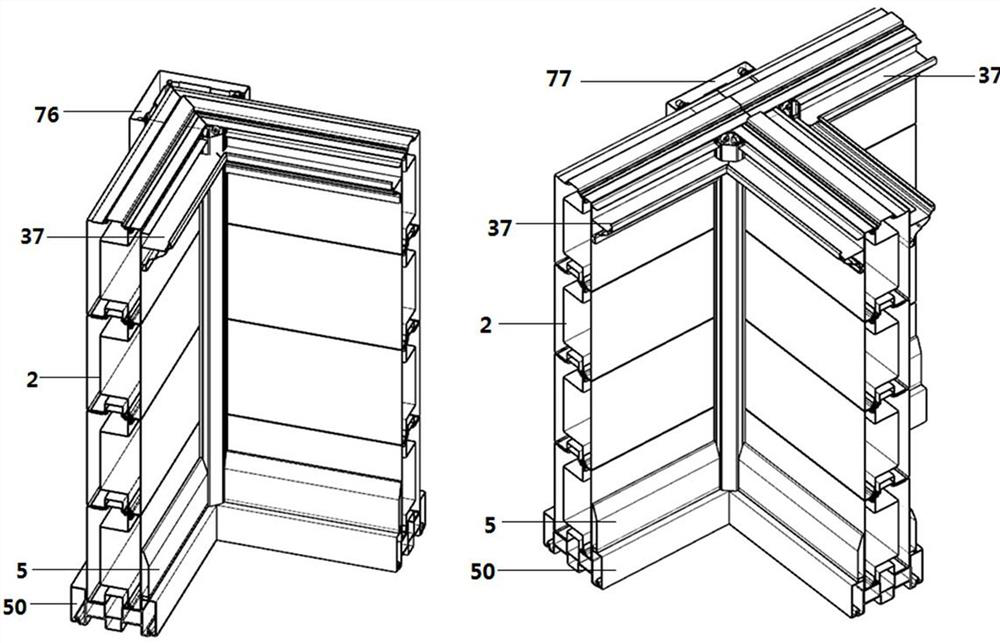

[0059] As the best implementation mode of the present invention, with reference to the attached figure 1 , the present invention is a one-storey building, comprising a wall structure made of aluminum alloy, a roof structure and a floor structure, the roof structure comprising a roof truss 9 and roof tiles 10, the floor structure comprising a floor 11, a ceiling gusset 12. The first keel 52 for supporting the floor 11 and the second keel 53 for supporting the ceiling gusset 12 . Its construction methods include:

[0060] a. Set out the wires on the completed foundation ground to determine the installation position of the wall structure.

[0061] The wall structure includes a wallboard, a first screw rod 3, a ring beam and a corner connector connecting the wallboard at the corner. Since this embodiment is a one-story house structure, the ring beam includes an upper ring beam 49 and a lower ring beam 50, the wallboard is located between the upper ring beam 49 and the lower ring...

Embodiment 2

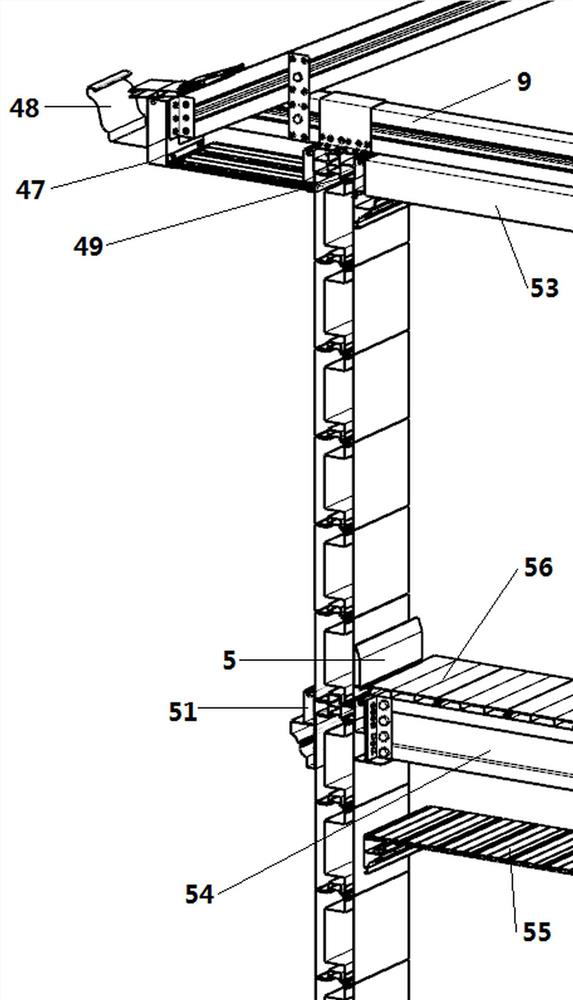

[0085] As a preferred embodiment of the present invention, with reference to the attached figure 2 , The present invention can be a multi-storey building, including a wall structure, a roof structure, a floor structure and at least one intermediate floor structure made of aluminum alloy. The two-storey building in this embodiment is introduced.

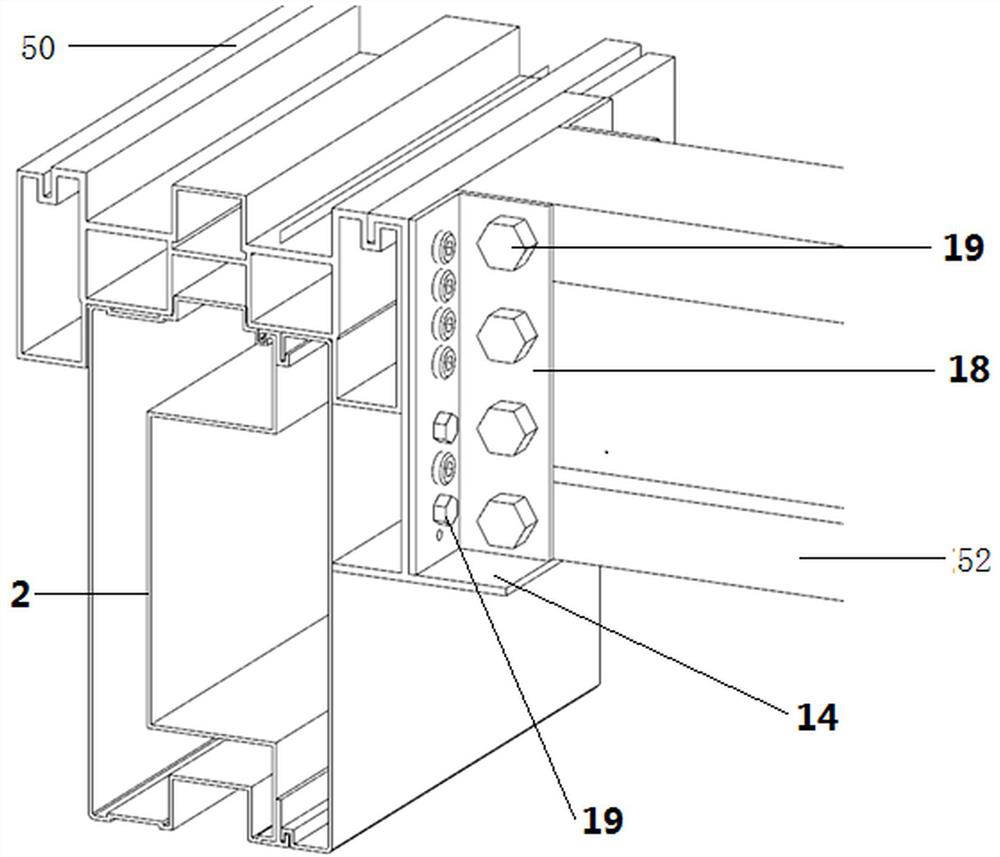

[0086] Structurally, compared with Embodiment 1, this embodiment has one more layer of intermediate floor structure, and an intermediate layer ring beam 51 is also correspondingly provided between the upper ring beam 49 and the lower ring beam 50, and the intermediate layer floor structure The structure includes an intermediate layer keel 54, an intermediate layer suspended ceiling 55 and an intermediate layer floor 56. The intermediate layer keel 54 is fixedly connected to the intermediate layer ring beam 51 through the keel hanger 14, and the intermediate layer suspended ceiling 55 is fixedly connected to the lower surface of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com