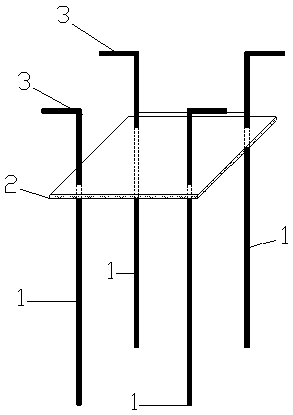

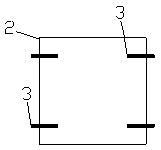

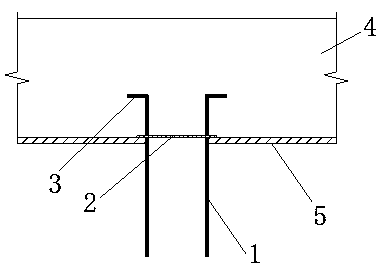

Constructional column top reinforced bar steel structure pre-embedded assembly and construction method

A technology for structural columns and reinforced steel, which is applied to the pre-embedded components of reinforced steel structures at the top of structural columns and the field of construction, can solve the problems of difficult removal of formwork at the top of structural columns, offset of steel bars, etc., and achieves fast and efficient installation, convenient construction and installation, and construction. The effect of guaranteed quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0032] Construction method flow: construction preparation→drawing deepening→processing and production of steel structure pre-embedded components→beam formwork installation→steel structure pre-buried components placement construction→cast-in-place beam reinforcement installation→cast-in-place beam concrete pouring construction→formwork removal construction

[0033] Construction preparations include joint review of drawings, construction plans, mechanical equipment, materials and labor preparations required for construction.

[0034] The drawing deepening includes deepening the embedded parts of the reinforced steel structure at the top of the structural column, making a blanking processing drawing, deepening the position of the structural column, and making a positioning and laying out diagram of the structural column.

[0035]Processing and production of steel structure pre-embedded components: According to the pre-embedded parts blanking processing drawing, the factory will ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com