Aluminum alloy formwork, connecting and compressing structure and connecting method thereof

A technology of aluminum alloy formwork and compression structure, which is applied in the connection parts of formwork/formwork/work frame, formwork/formwork member, building structure, etc. and other problems, to achieve the effect of saving the time of disassembly, improving the utilization rate and improving the efficiency of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

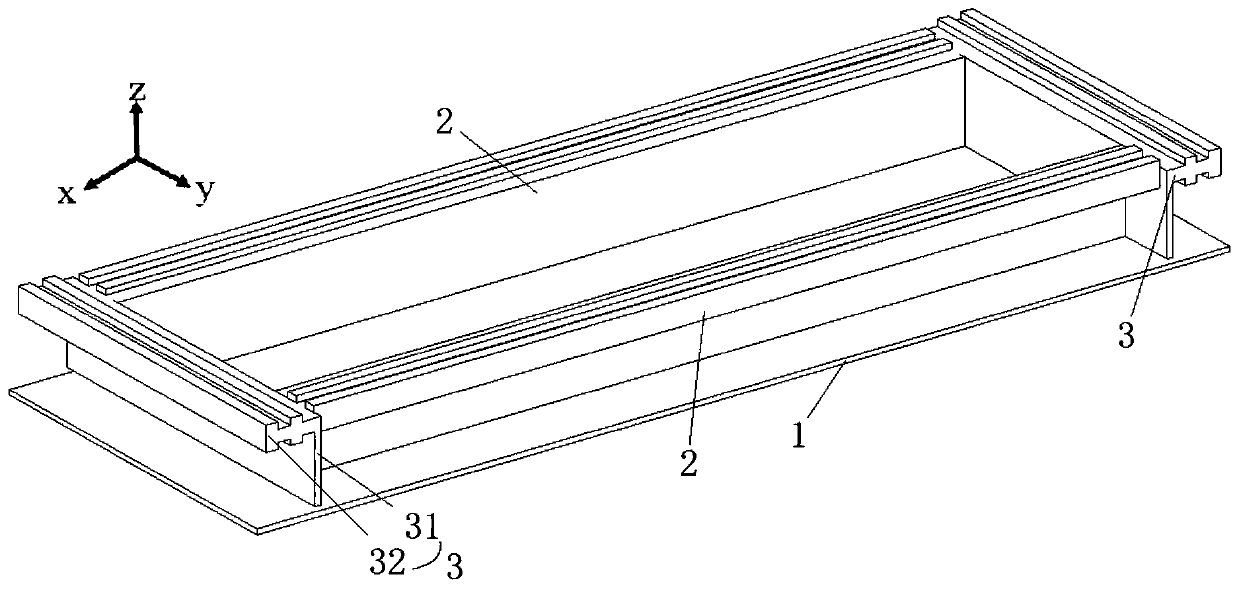

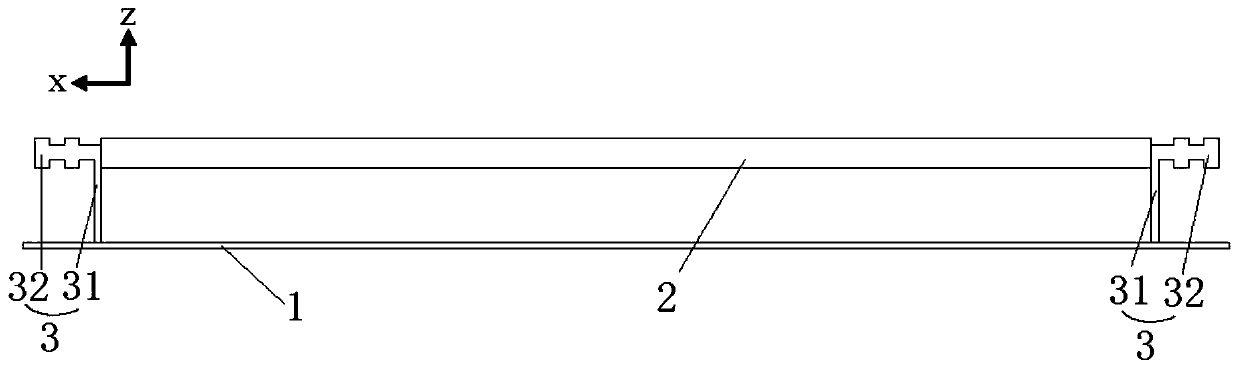

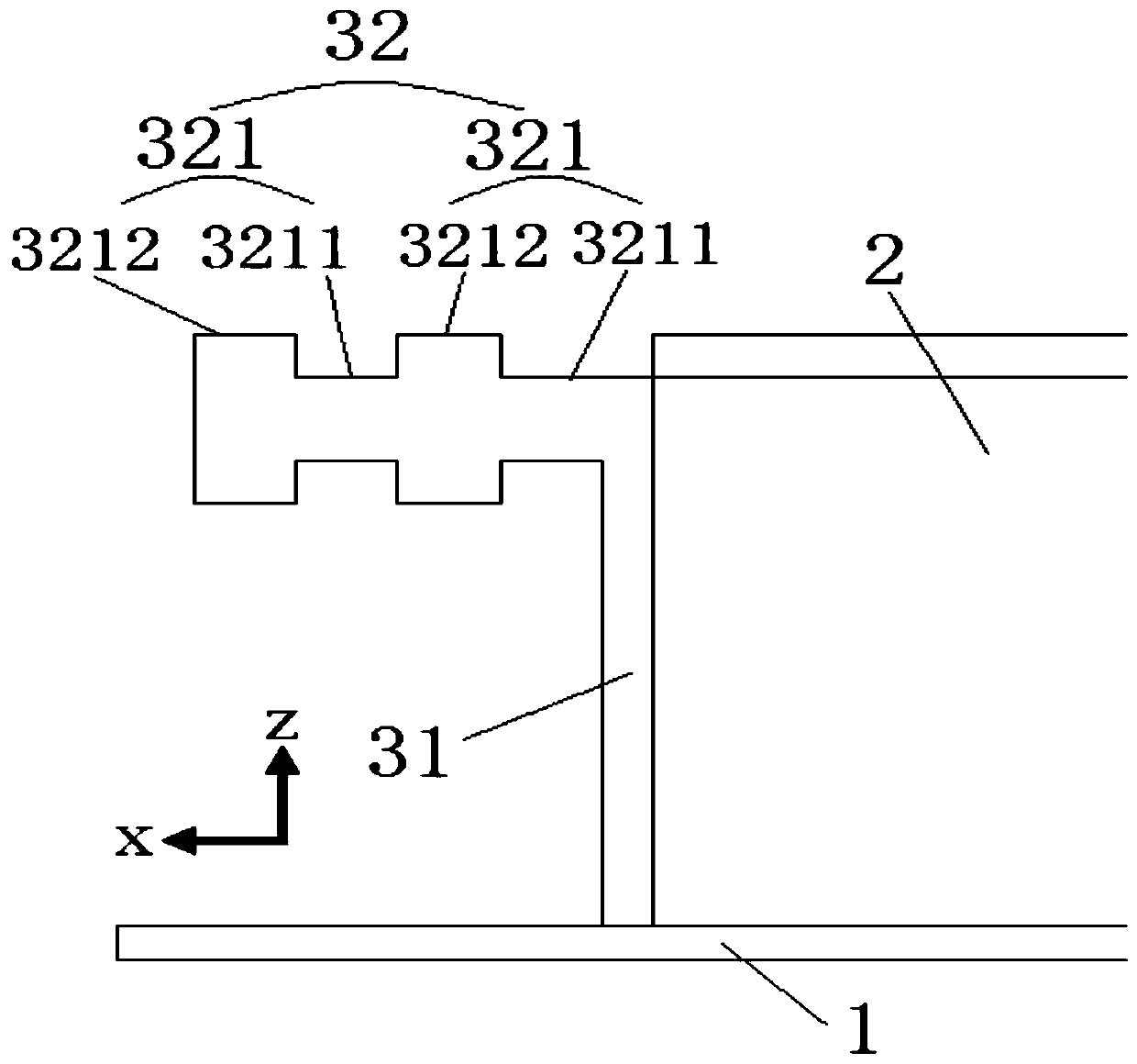

[0035] Such as Figure 1-2 As shown, an aluminum alloy formwork includes a plane plate 1, a stiffener side plate 2, and a stiffener connecting plate 3, and the stiffener side plate 2 is along the X-axis direction of the plane plate 1, at a certain distance from the transverse edge of the plane plate 1 , vertically fixed on the plane plate 1, two stiffener side plates 2 are parallel to each other; the stiffener connecting plate 3 includes a side support plate 31 and a connector 32; The Y-axis direction is fixed at a certain distance from the edge of the plane plate 1 and vertically fixed on the plane plate 1 , and the two side support plates 31 are parallel to each other.

[0036] The width of the connecting piece 32 in the X-axis direction is smaller than the distance from the end of the plane plate 1 in the X-axis direction to the surface of the side support plate 31, which ensures the seamless connection between the two aluminum alloy templates along the X-axis direction. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com