Emergency shutoff device with both remote control and local mechanical control functions

A mechanical control and remote control technology, applied in the direction of wellbore/well valve devices, mechanical equipment, measurement, etc., can solve the delay or failure of solenoid valve control, which is not conducive to eliminating hidden dangers of safety accidents, and cannot realize automatic emergency shut-off valves. Open and close problems, to improve reliability and accuracy, to eliminate hidden dangers of safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

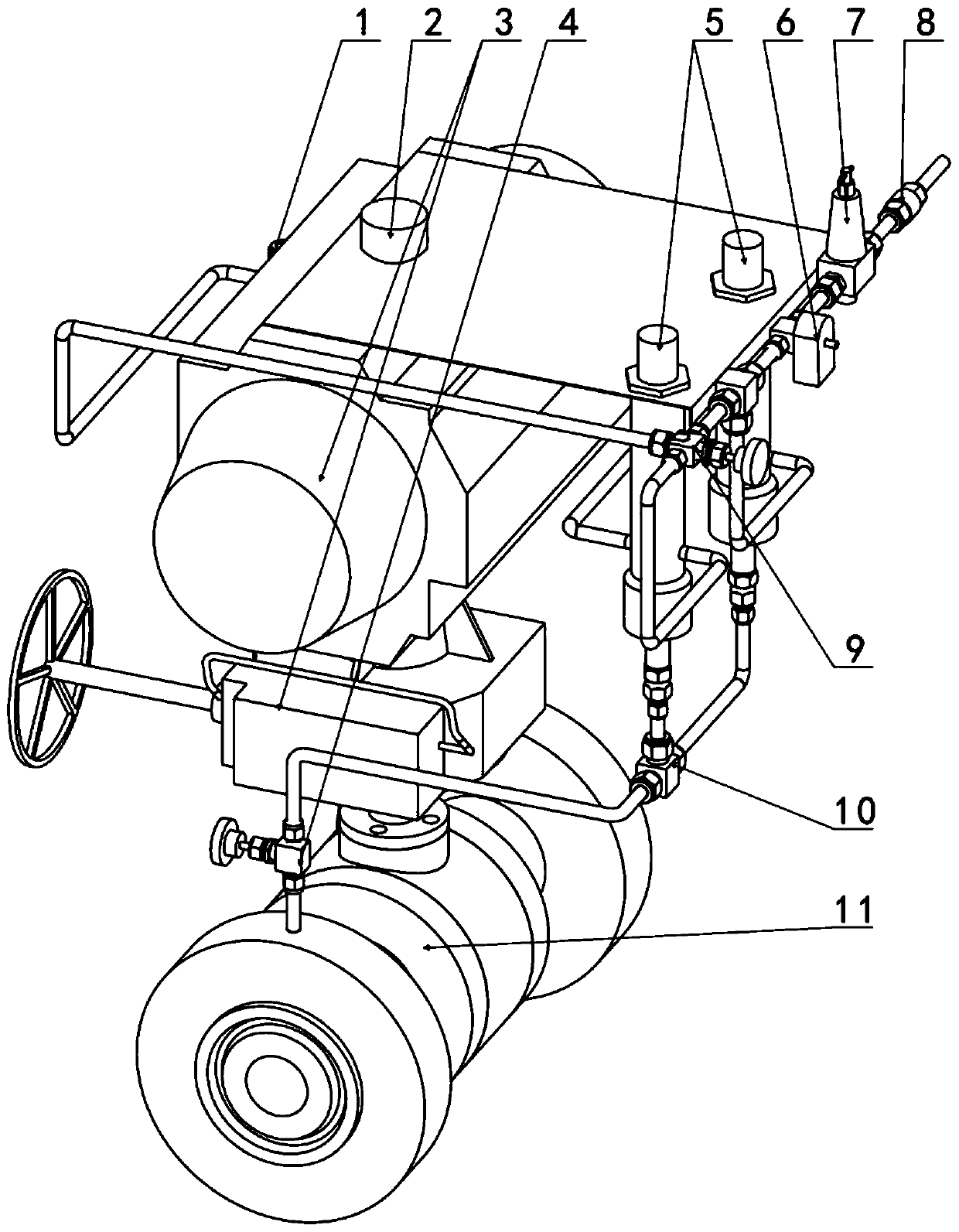

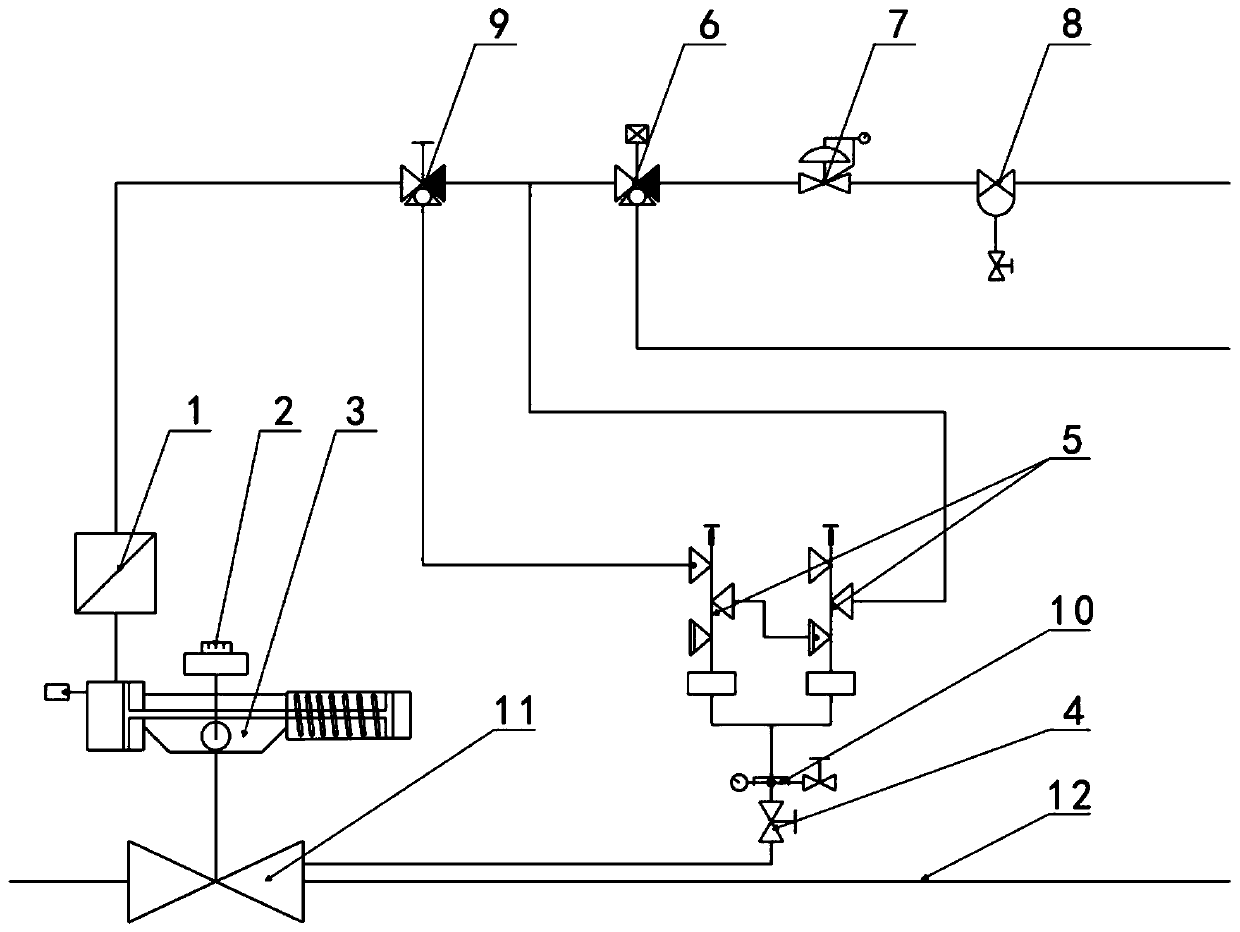

[0018] like figure 1 and figure 2 As shown, the emergency shut-off device with both remote control and local mechanical control functions in the present invention includes an emergency shut-off valve 11, a pneumatic actuator 3, a quick release valve 1, a solenoid valve 6, and an air compressor (that is, an air compressor, not shown in the figure), pressure transmitter (i.e. pressure sensor, not shown in the figure), controller (preferably PLC, not shown in the figure), three-way valve 9 and high and low pressure pilot valve 5, the air compressor The compressed air outlet is sequentially connected to the solenoid valve 6, the quick release valve 1 and the cylinder inlet of the pneumatic actuator 3. The transmission rod of the pneumatic actuator 3 is connected to the valve stem of the emergency shut-off valve 11, and the inlet of the emergency shut-off valve 11 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com