A high-pressure gas generating device and a high-pressure and accurate combustion characteristic testing system

A technology of combustion characteristics and testing system, which is applied in chemical analysis using combustion, liquid variable capacity machinery, pump components, etc. problems, to meet the needs of the laboratory environment, increase stability and continuity, and reduce the volume of the gas chamber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

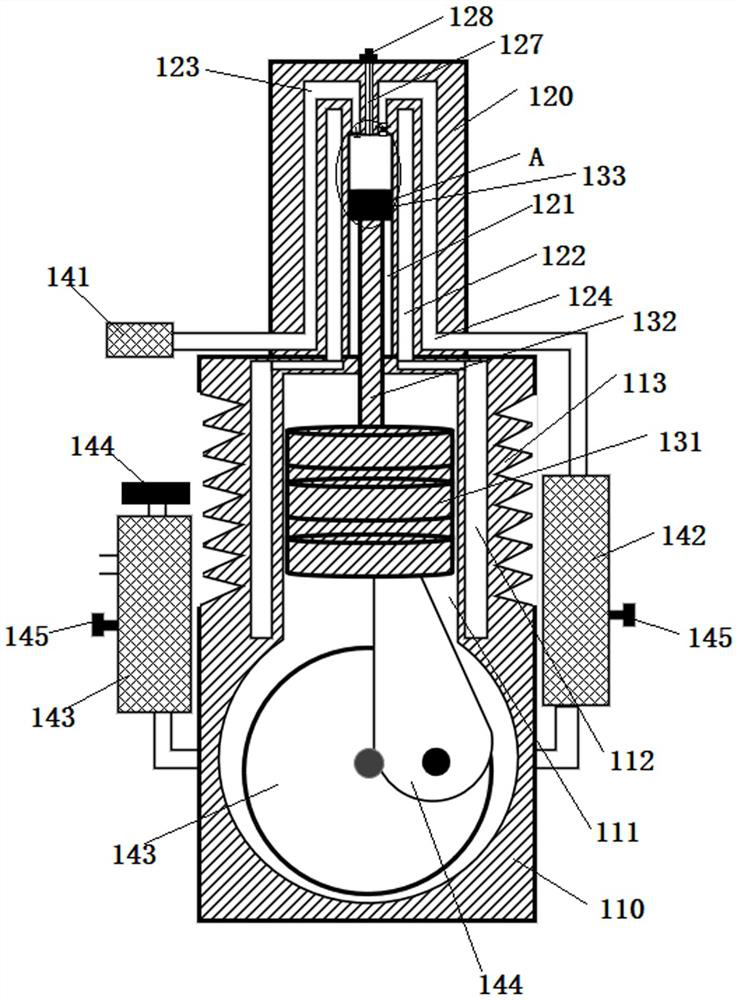

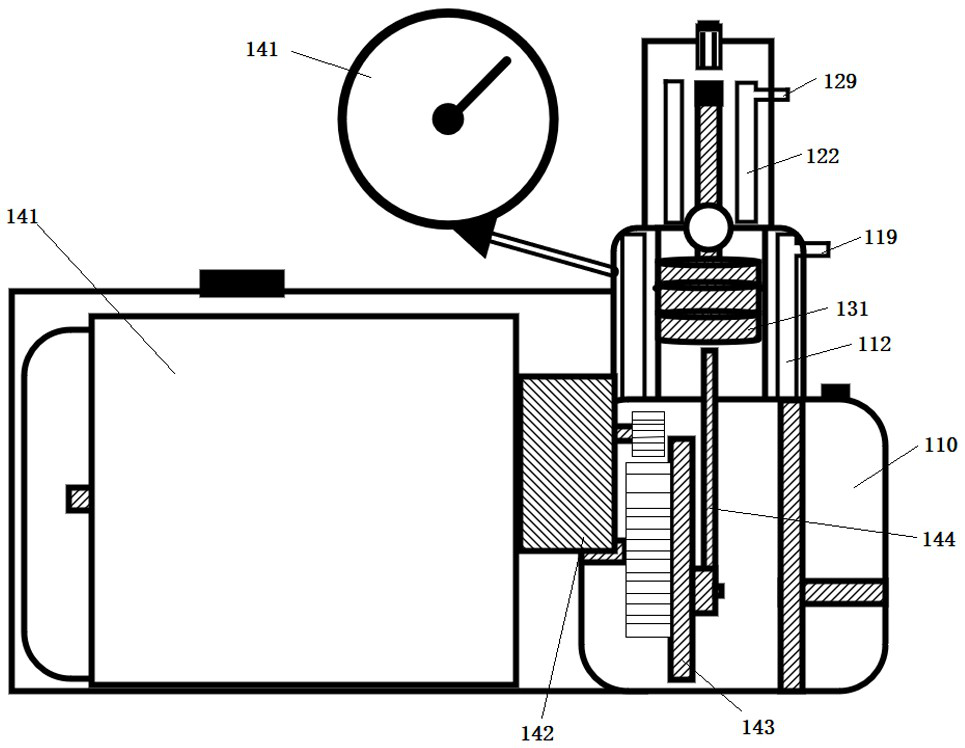

[0038] Such as Figure 1 to Figure 3 As shown, a high-pressure gas generating device includes a compression part and a driving part.

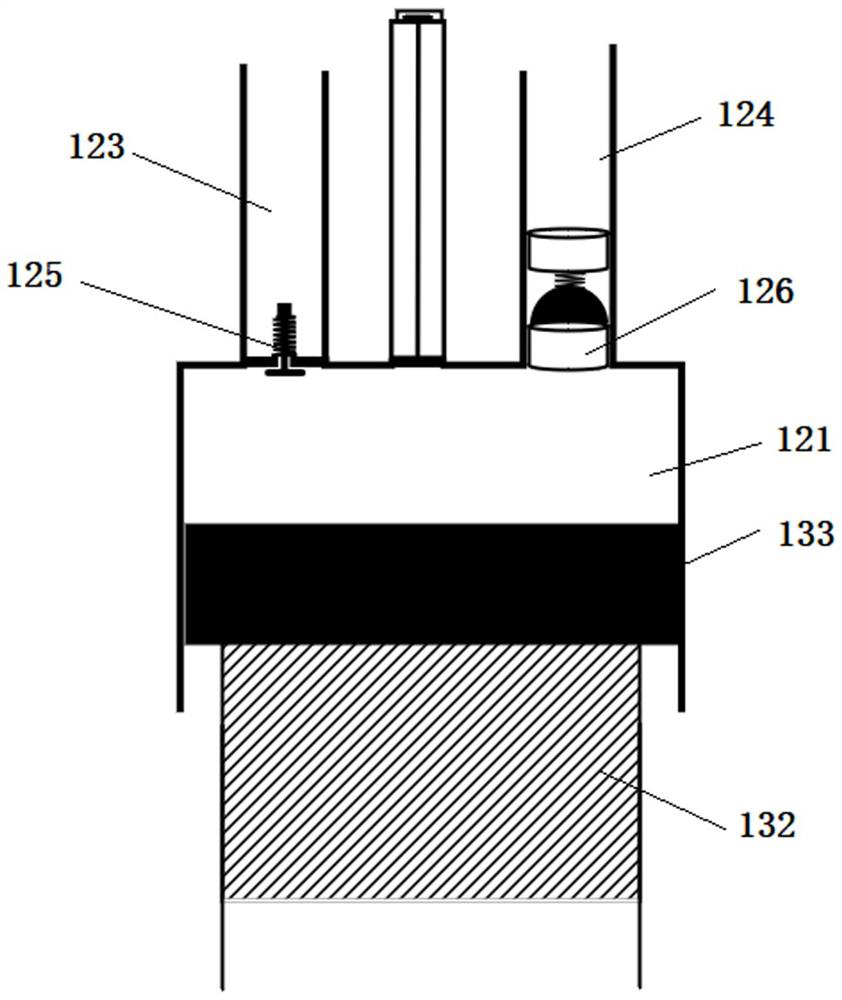

[0039] Wherein, the compression part includes a casing 110, a high-pressure cylinder 120, a piston device and a purification device;

[0040] The casing 110 is a hollow structure. A guide cylinder 111 is formed inside the casing 110. A first annular water tank 112 is processed on the casing 110. The first annular water groove 112 is arranged around the outside of the guide cylinder 111. The outer side of the first annular water groove 112 is arranged There are cooling fins 113 . The high-pressure cylinder 120 is a hollow structure, and a compression cylinder 121 is formed in the high-pressure cylinder 120....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com