A cyclone air sterilizer

An air sterilizer and cyclone technology, applied in the field of air purification, can solve the problems of easy accumulation of pollutants on the surface of the filter screen, high air treatment efficiency, poor filtering effect, etc., so as to reduce the number of cleanings, prolong the service life, and facilitate disassembly. The effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

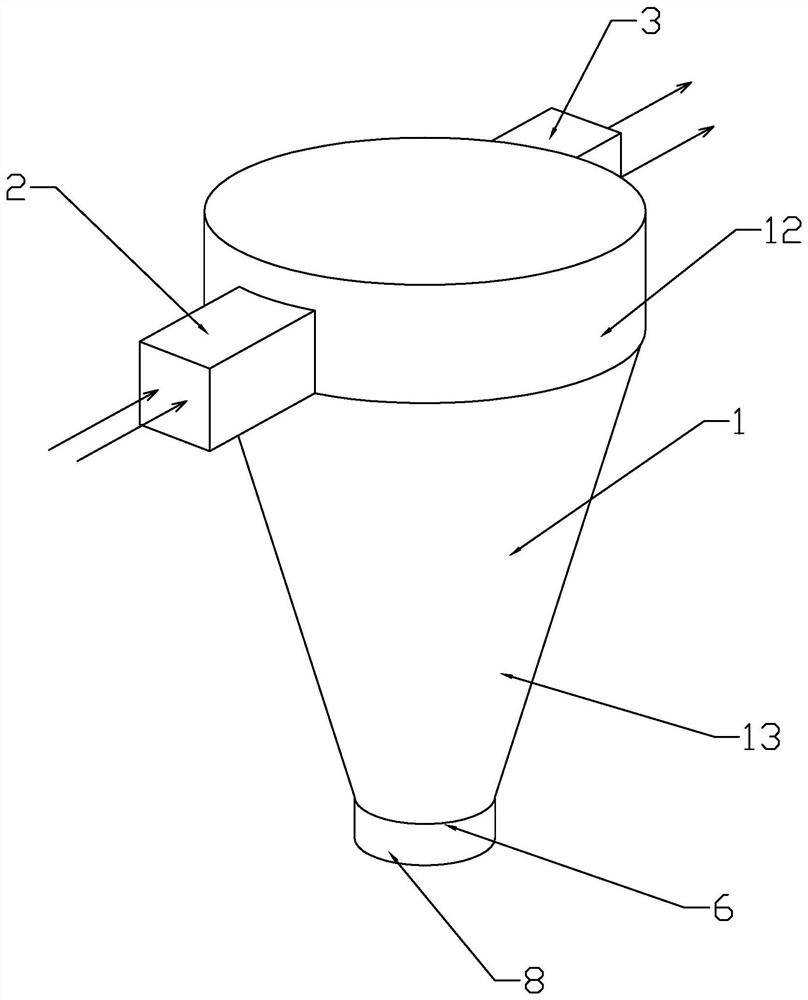

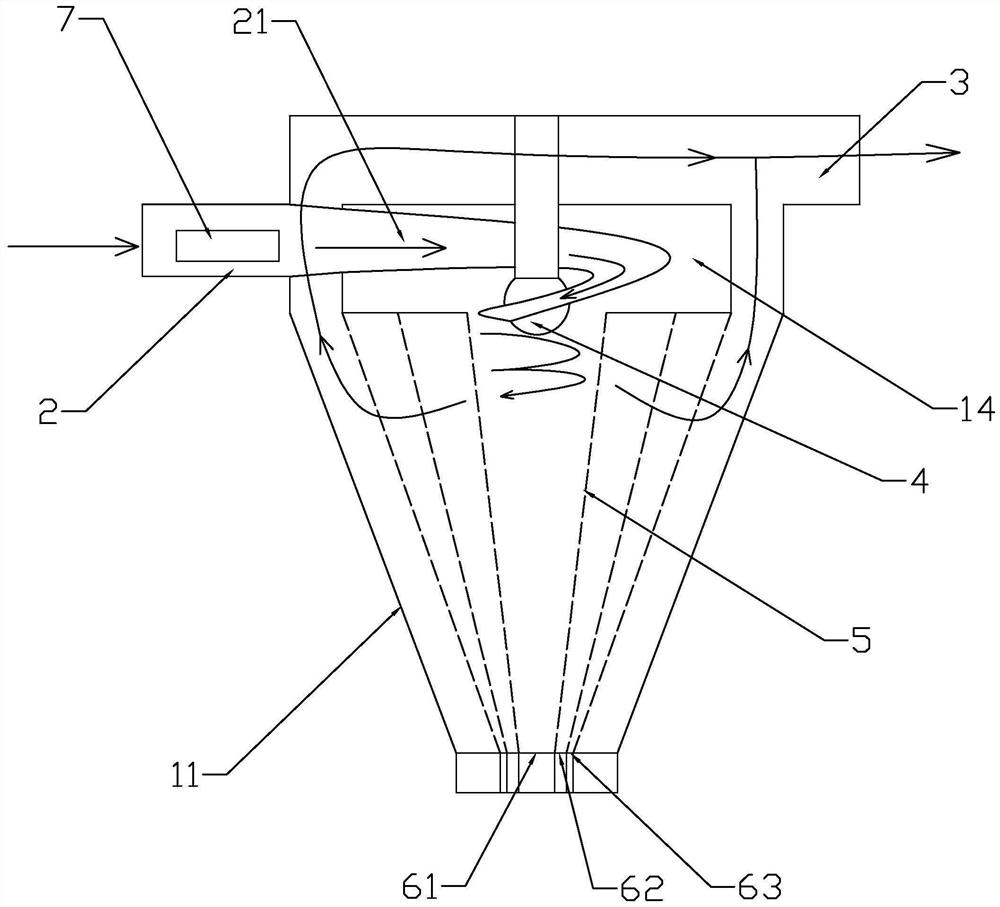

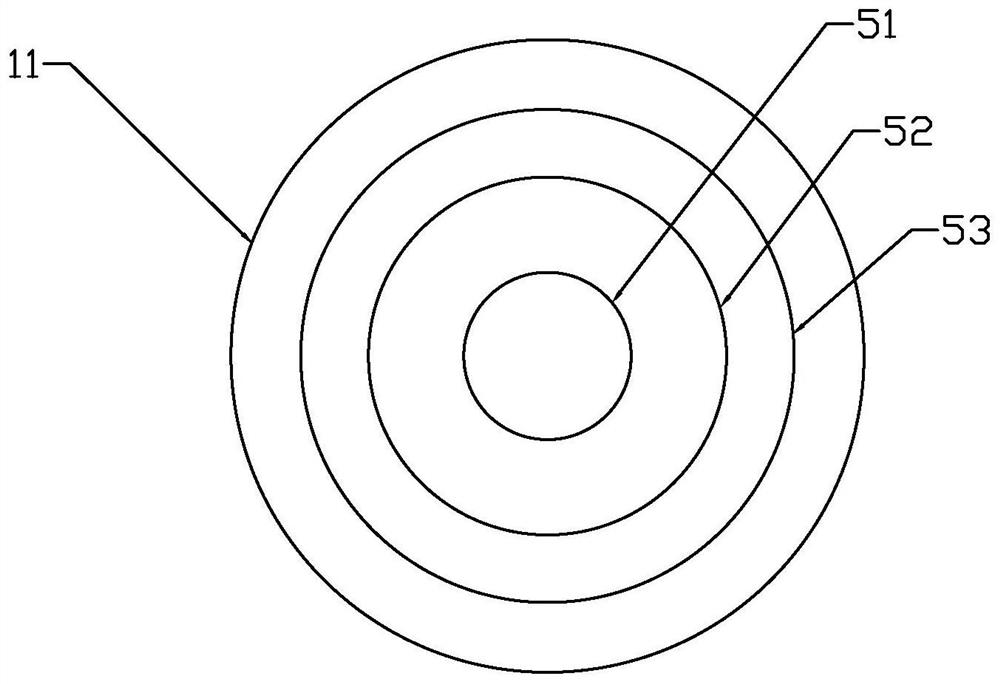

[0034] Such as figure 1 , figure 2In the shown embodiment 1, a cyclone air sterilizer includes a cylinder body 1 and a filter screen 5 arranged in the cylinder body 1, the cylinder body 1 includes a connected upper cylinder 12 and a lower cylinder 13, and the upper cylinder 12 is a cylinder The cylinder body, the lower cylinder 13 is set in a cone structure, the diameter of the upper cylinder is consistent with the diameter of the top of the lower cylinder, the upper cylinder 12 is provided with an air inlet 2, and the air inlet 2 is equipped with a fan 7, and is connected with a spiral air inlet pipe 21. The other side of the upper barrel 12 is provided with an air outlet 3 . Such as figure 2 As shown, the upper cylinder 12 is provided with a cylindrical air inlet sealing chamber 14 , the air inlet pipe 21 is arranged in the air inlet sealing chamber 14 , and one side of the air inlet sealing chamber 14 communicates with the air inlet 2 . Such as image 3 As shown, the ...

Embodiment 2

[0037] Such as figure 1 , Figure 4 In the shown embodiment 2, a cyclone air sterilizer has roughly the same structure as that of the embodiment 1, the difference is that the filter screen 5 is an integrated spiral structure, forming a three-layer structure, which is large at the top and small at the bottom. Cone structure, including the first filter section 54 of the first layer of dust filter layer from inside to outside, the second filter section 55 of the second layer of HEPA filter layer, and the third filter section 56 of the third layer of titanium dioxide filter layer, three The apertures of each filter segment decrease successively, the cavity surrounded by the first filter segment 54 is the first inner cavity, the cavity surrounded by the second filter segment 55 is the second inner cavity, and the cavity surrounded by the third filter segment 56 It is the third inner cavity, an outer cavity is formed between the third filtering section 56 and the lower cylinder wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com