Drying, condensation and dehumidification integrated machine

An all-in-one machine and drying technology, which is applied in the direction of drying solid materials, drying gas layout, local agitation dryers, etc., can solve the problems of rising costs, direct moisture discharge is not in line with environmental protection, and the difficulty of improving the control of production links. well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further understand the content, features and effects of the present invention, the following examples are given in detail.

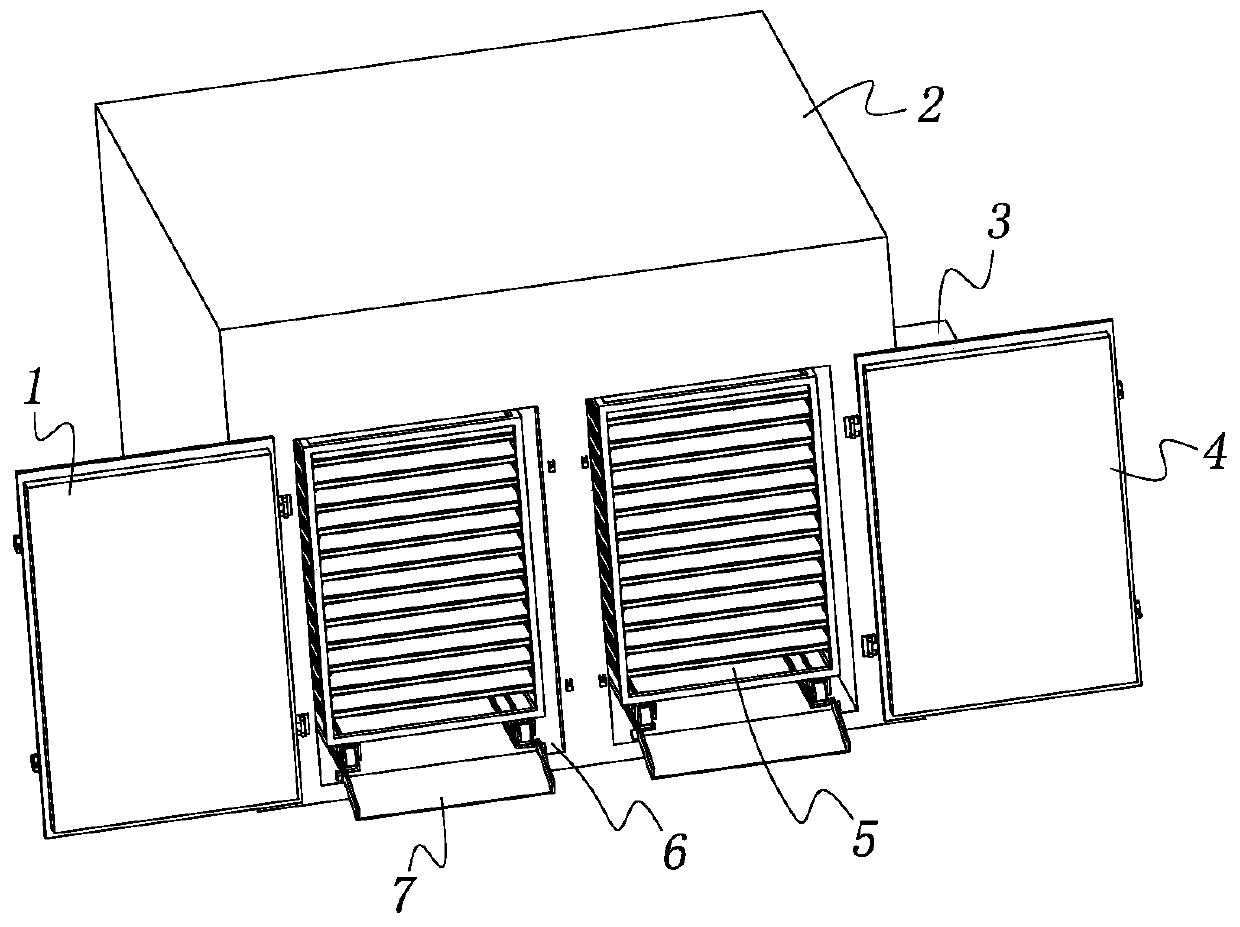

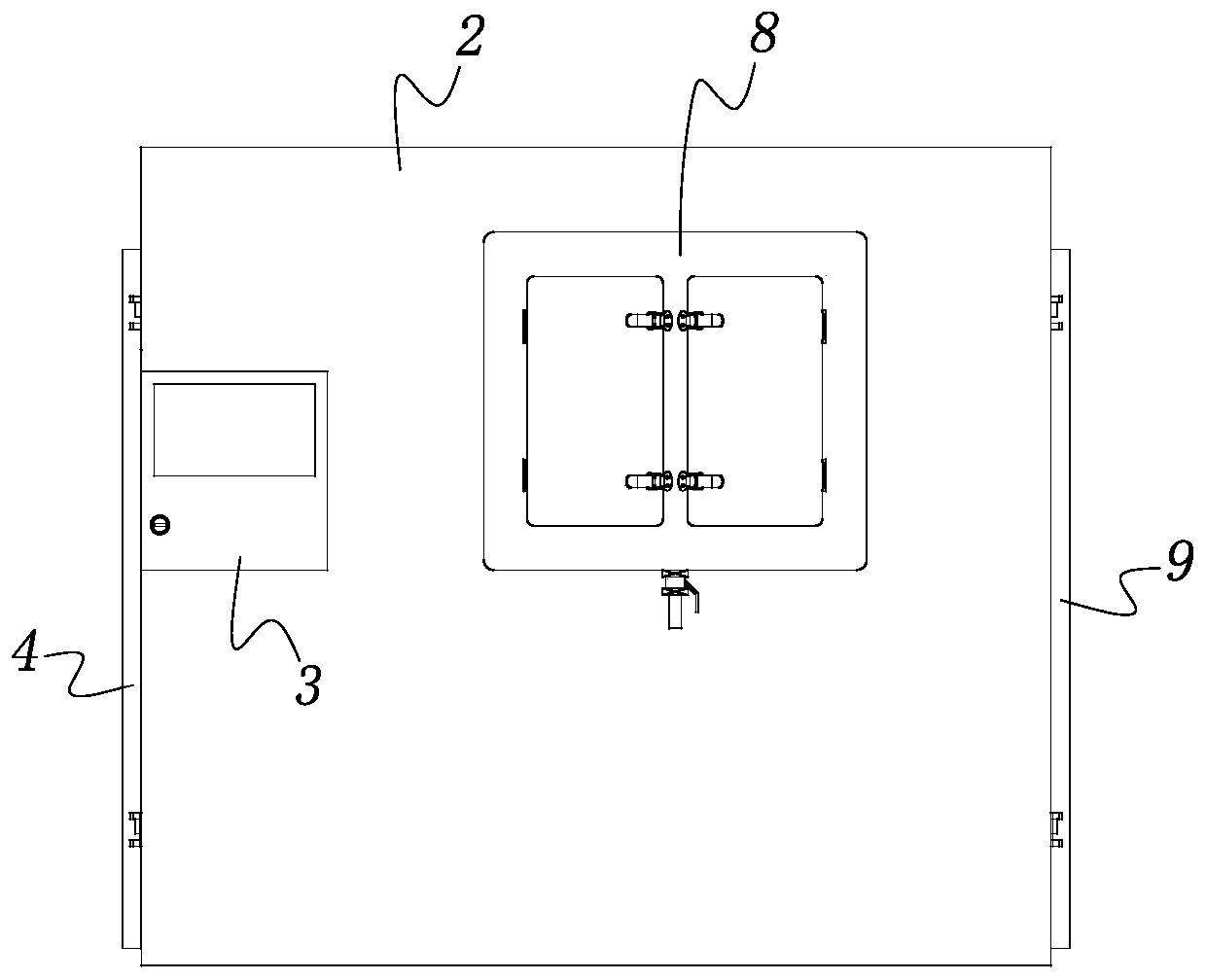

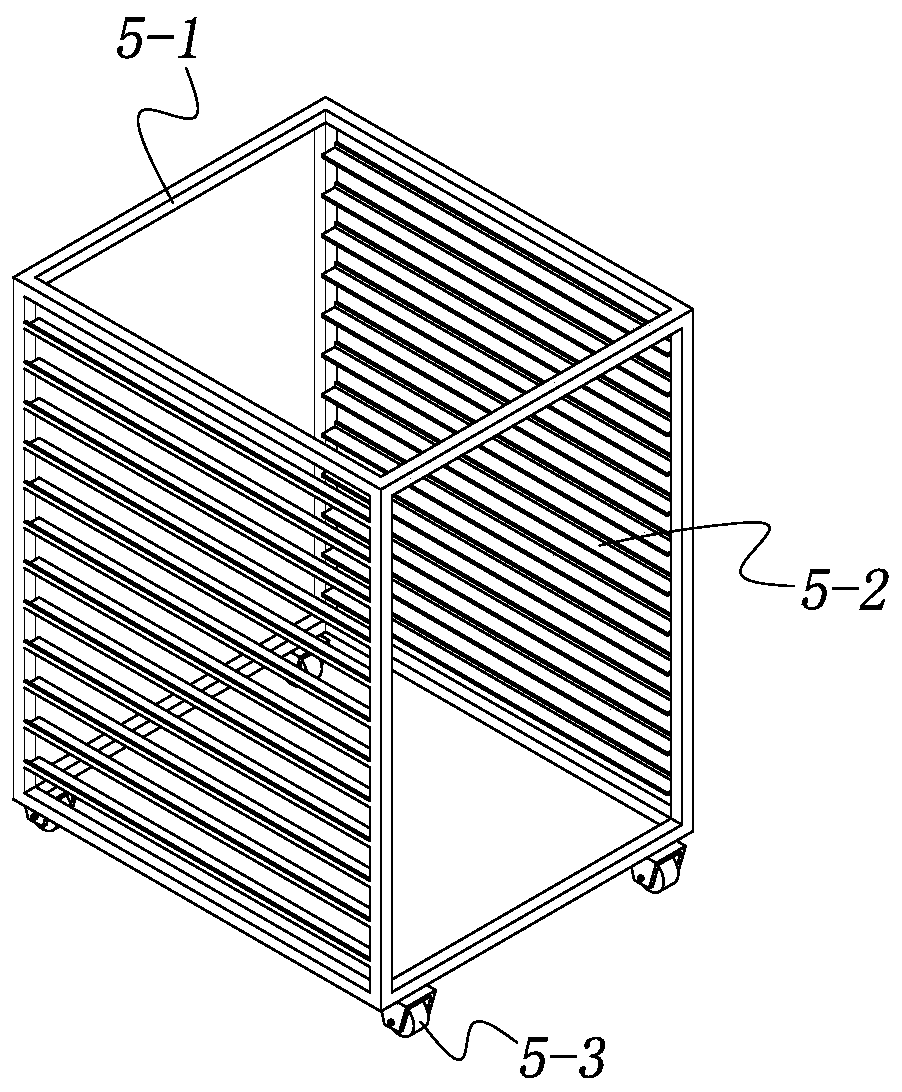

[0026] See figure 1 and figure 2 , the drying, condensing and dehumidifying all-in-one machine of the present invention comprises a drying box 2 with a front door 6 on the front, a front door is provided on the front door 6, a feeding cart 5 is provided in the drying box 2, and a drying box 2 is provided on the side of the drying box 2. Condensation dehumidification device 8 is arranged.

[0027] The material to be dried is placed on the skip 5, and the condensation and dehumidification device 8 is used to condense and dehumidify the moisture generated during the drying process, and continuously liquefy the moisture and volatile components in the moisture.

[0028] As shown in the figure, in the present embodiment, there are two left and right front doorways 6 on the front of the drying box 2, and a front left door 1 is installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com