Flaky sample stress corrosion loading device and using method

A technology of loading device and sheet-like sample, applied in the direction of measuring device, weather resistance/light resistance/corrosion resistance, and application of stable tension/pressure test material strength, etc., can solve the problem of lack of key materials, and achieve simple structure design , Loading load can prevent the effect of rotation or twisting deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

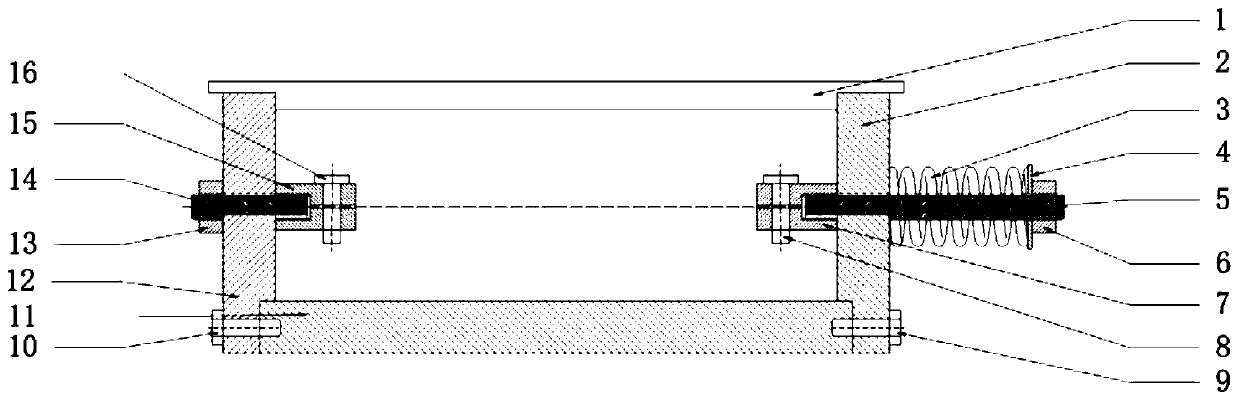

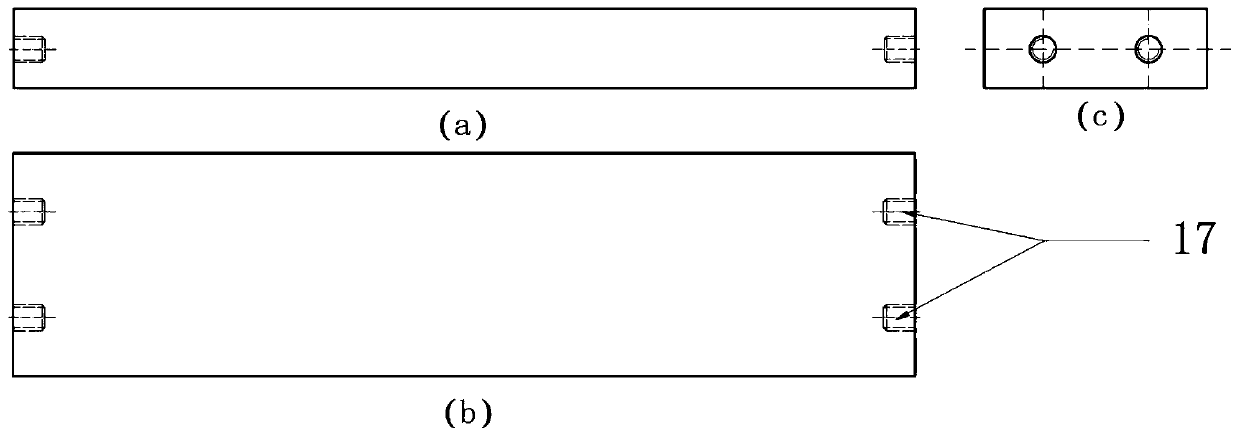

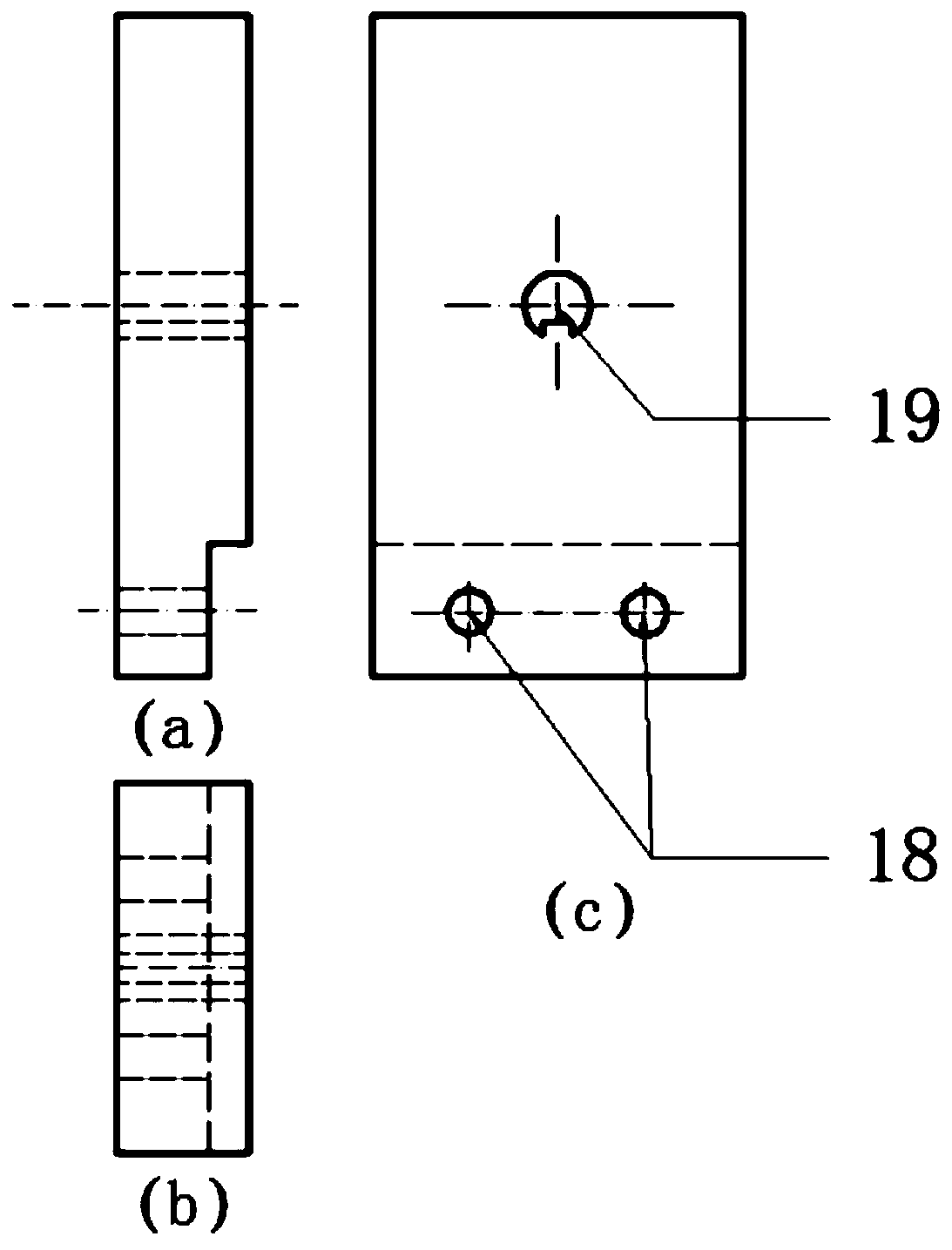

[0061] In the embodiment, the spring is made of 65Mn steel, with a wire diameter of 6mm, an inner diameter of 12mm, a total length of 70mm, a total number of turns of 9.5, a maximum compression of 15mm, and a Hooke coefficient of 316.8N / mm. The surface of the spring is painted with Prevent the spring from corroding during the test; the rest of the loading device is made of 304 stainless steel; the sheet test is a solid solution 304 stainless steel sample, the length of the sample gauge section is 50mm, the width is 10mm, and the thickness is 1mm. The yield strength of solid solution 304 stainless steel (σ s ) is 289MPa; according to the test requirements, the loading load is 1.0σ s , The compression of the spring is 9.12mm. Figure 8 A diagram of the different parts of the loading device. Figure 9 It is the physical picture after installing the sample and carrying out constant load loading. The loading device can study the stress corrosion-related properties of 304 stainle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com