Light emitting diode and manufacturing method thereof

A technology of light-emitting diodes and light-emitting layers, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as infiltration into light-emitting diodes, short circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0295] Reference will now be made in detail to the exemplary embodiments of the present invention, examples of which are illustrated in the accompanying drawings. Wherever possible, the same reference numbers will be used in the drawings and description to refer to the same or like parts.

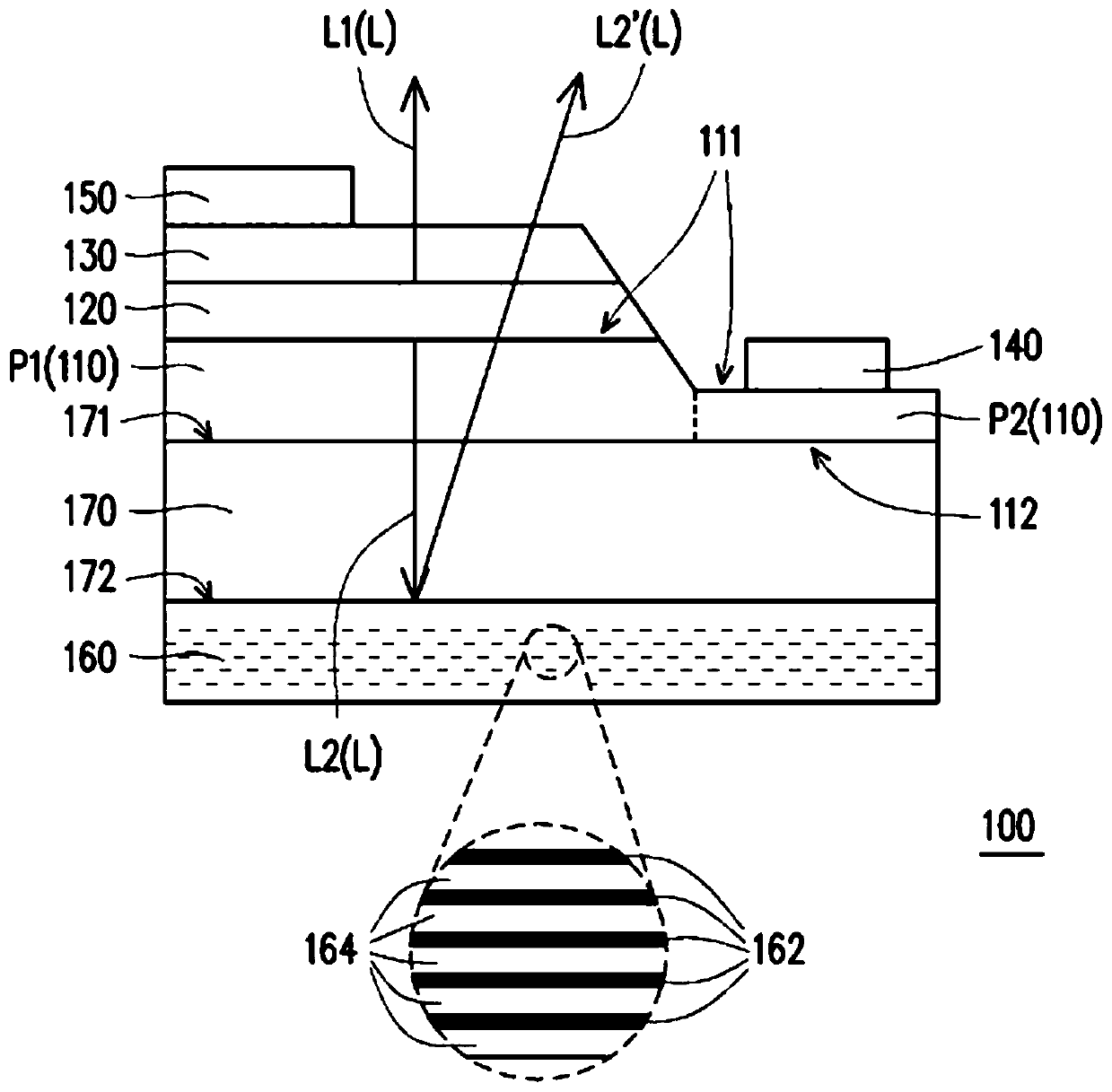

[0296] Figure 1A A cross-sectional view of a light emitting diode according to an embodiment of the present invention is shown. Please refer to Figure 1A ,in particular, Figure 1A Shown is a horizontal LED, and is one type of LED that can be applied to wire bonded packages. The light emitting diode 100 includes a first type semiconductor layer 110 , a light emitting layer 120 , a second type semiconductor layer 130 , a first current conducting layer 140 , a second current conducting layer 150 and a Bragg reflection structure 160 . In this embodiment, one of the first-type semiconductor layer 110 and the second-type semiconductor layer 130 is an N-type semiconductor layer (for example, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap