a tio 2 -m x the w 3 -sio 2 Composite airgel and its preparation method

A composite airgel and composite gel technology, applied in the field of TiO2-MxWO3-SiO2 composite airgel and its preparation, to achieve high near-infrared absorption/shielding performance, excellent near-infrared shielding and heat insulation performance, and uniform distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] TiO of the present invention 2 -M x WO 3 -SiO 2 The in-situ synthesis / atmospheric pressure drying process preparation method of the composite airgel specifically includes the following steps:

[0041] ①Dissolve tungstate in water to obtain a tungstate solution with a concentration of 0.01-5mol / L;

[0042] ②Dissolve silicate into water to obtain a silicate solution with a concentration of 0.01-5mol / L;

[0043] ③Convert the prepared tungstate solution and silicate solution into tungstic acid solution and silicic acid solution respectively by cation exchange method, the tungstic acid solution pH=1~5, the silicic acid solution pH=1~5 6;

[0044] ④Measure a certain volume of silicic acid solution and tungstic acid solution, mix under stirring conditions, and add a certain amount of M salt and inducer, stir and mix evenly, and prepare a mixed sol;

[0045] ⑤Aging the mixed sol at a temperature of 20-90°C until it turns into a gel;

[0046] ⑥The composite gel block is p...

Embodiment 1

[0066] Embodiment 1 prepares 0.4TiO 2 -Cs x WO 3 -2SiO2 2 composite airgel

[0067] ① Preparation of silicic acid and tungstic acid solutions by ion exchange method

[0068] Preparation of silicic acid: Measure 60mL of industrial water glass with a modulus of 3.0, press V 水玻璃 :V 水 =1:4 diluted with deionized water, and then ion-exchanged through a styrene-based cation-exchange resin to obtain silicic acid with a pH of 2 to 3;

[0069] Preparation of tungstic acid: first weigh 19.791g sodium tungstate dihydrate and dissolve in 80mL deionized water to prepare Na 2 WO 4 solution, and then undergo ion exchange through a styrene-based cation exchange resin to obtain a tungstic acid solution with a concentration of 0.75mol / L and a pH of 1.5-3.

[0070] ②Preparation of mixed sol and gel

[0071] Under stirring conditions, weigh 40mL of silicic acid solution, 31mL of tungstic acid solution, 2.1g of cesium sulfate, and 1.646g of citric acid monohydrate and mix them in turn, st...

Embodiment 2

[0080] Embodiment 2 prepares 0.6TiO 2 -Cs x WO 3 -2SiO2 2 composite airgel

[0081] 1. prepare silicic acid and tungstic acid solution by ion exchange method with step 1. in embodiment 1;

[0082] 2. prepare mixed sol and gel, same as embodiment 1 step 2.;

[0083] ③Composite gel aging and solvothermal reaction

[0084] Measure 30ml of absolute ethanol, add 6.935g of citric acid monohydrate, add 4.8mL of butyl titanate dropwise under stirring to prepare the gel block reaction precursor solution, and place the composite gel block in the reaction precursor solution. Aging for 6h, then reacting at 190°C for 72h;

[0085] 4. modification and normal pressure drying of the composite gel, same as step 4. in Example 1;

[0086] 5. the heat treatment of composite airgel, with step 5 in embodiment 1;

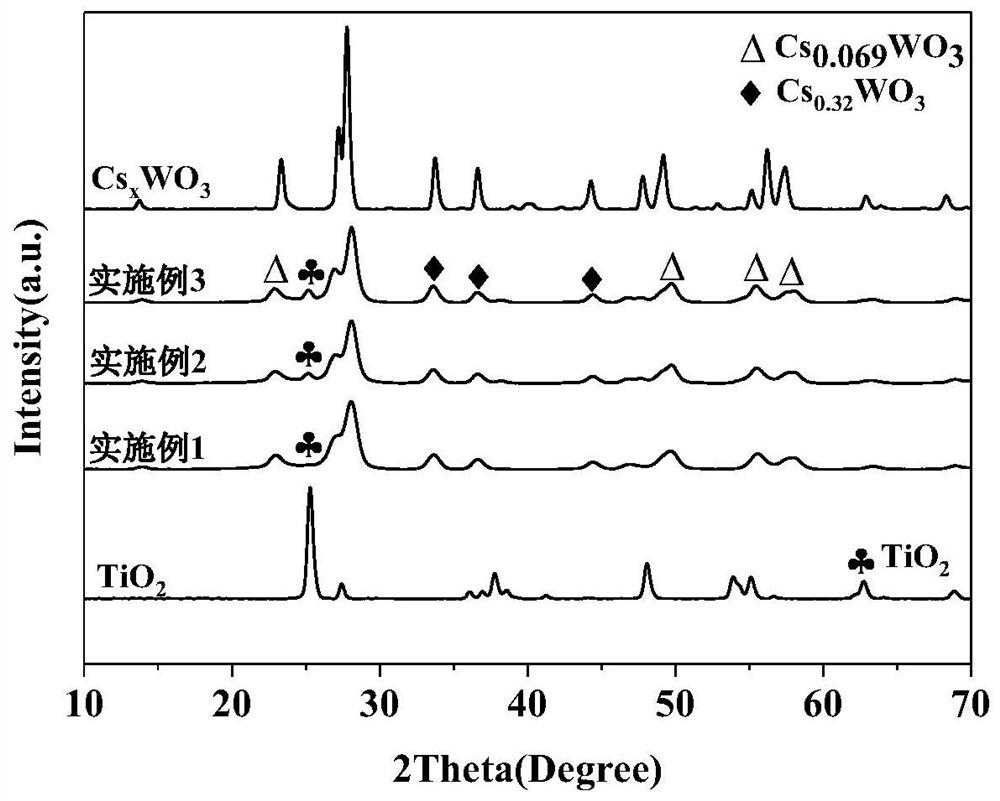

[0087] It has been determined that the 0.6TiO prepared by this method 2 -Cs x WO 3 -2SiO2 2 The main crystal phase in the composite airgel is Cs 0.32 WO 3 , and contains a s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap