Blockage-free multilevel smasher for processing heparinoid

A non-clogging, pulverizer technology, applied in the direction of grain processing, etc., can solve the problems of long crushing time, material clogging, machine idling, etc., and achieve the effect of improving crushing efficiency, convenient opening, and convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

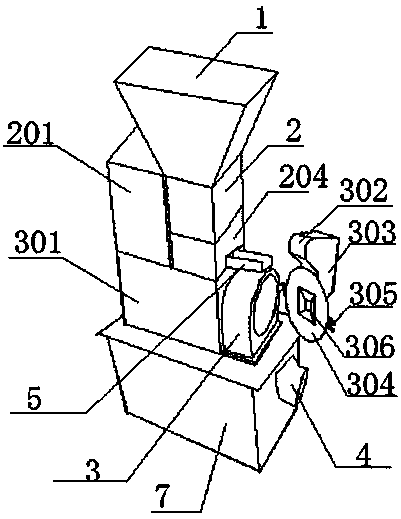

[0037] The present invention relates to the technical field of material crushing. The shredder structure commonly used in machinery is applied to the field of drug crushing, and discloses a non-blocking multi-stage pulverizer. The pulverizer mainly includes a feeding funnel 1 communicating with the feeding funnel 1. The multi-stage crushing mechanism and the total discharge port 4 connected with the multi-stage crushing mechanism, the multi-stage crushing mechanism includes a primary crushing chamber 2 and a secondary crushing chamber 3 located below the primary crushing chamber 2, see the attached figure 1 . The feeding funnel 1 and the multi-stage crushing mechanism are all arranged on the table top of the box body 7, and the total discharge port 4 is located on the side wall of the box body 7, and communicates with the multi-stage crushing mechanism through the discharge channel 6, see the attached figure 1, the detailed structure is as follows:

[0038] The structure of t...

Embodiment approach 2

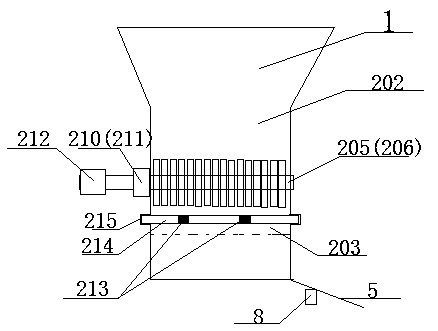

[0052] This embodiment is a further optimization of Embodiment 1. The specific optimization plan is: on the front and rear inner walls of the first-stage crushing chamber 2, there are several scraper blades 209 detachably connected at intervals (note: the first-stage crushing chamber 2 Among the four sides of the cavity, the two sides through which the knife shaft passes are marked as the left and right sides, and the sides parallel to the knife shaft are marked as the front and rear sides, and scraper blades 209 are arranged on the inner walls of the front and rear sides to scrape The material blades 209 are all plugged into the gap formed by the cutter head 207 on the driving knife shaft 205 and the driven knife shaft 206, and the scraper blades 209 do not affect the rotation of the knife shaft, that is, the scraper blades 209 on the front side are plugged into the active knife shaft. In the gap formed by the cutter disc 207 of the shaft 205 , the scraper blade 209 on the inn...

Embodiment approach 3

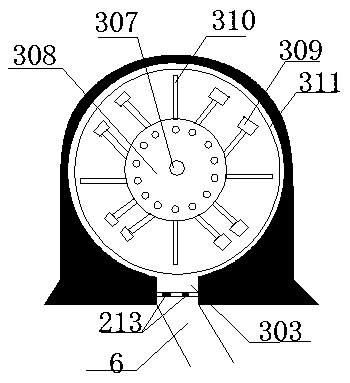

[0056] This embodiment is a further optimization of Embodiment 2. The specific optimization plan is: a pair of parallel magnetic pumps 213 are arranged horizontally at the discharge port B203 of the primary crushing chamber 2 and the discharge port D303 of the secondary crushing chamber 3. A pair of magnetic pumps 213 is arranged on the bracket 214, and the bracket 214 can be slidably connected to a pair of slide rails 215, so that the magnetic pump 213 can slide out of the crushing device through the slide rails 214 for cleaning.

[0057] See attached Figure 7 , the magnetic pump 213 is horizontally arranged at the discharge ports B and D, the support 214 is a square frame, the two ends of the magnetic pump 213 are detachably connected to the two ends of the square frame support 214, and the side walls at the two ends of the discharge ports B and D The top is respectively indented to form a pair of slide rails 215 , and the other two ends of the square frame slide inside the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com