Rapid self-centering clamping device for large-sized bearing ring workpiece

A self-centering clamping and bearing ring technology, which is applied in positioning devices, metal processing machinery parts, clamping, etc., can solve the problems that the machining accuracy of workpieces cannot be effectively guaranteed, the labor intensity of operators is high, and it takes a lot of time. Achieve the effect of improving clamping accuracy, high repeat positioning accuracy and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

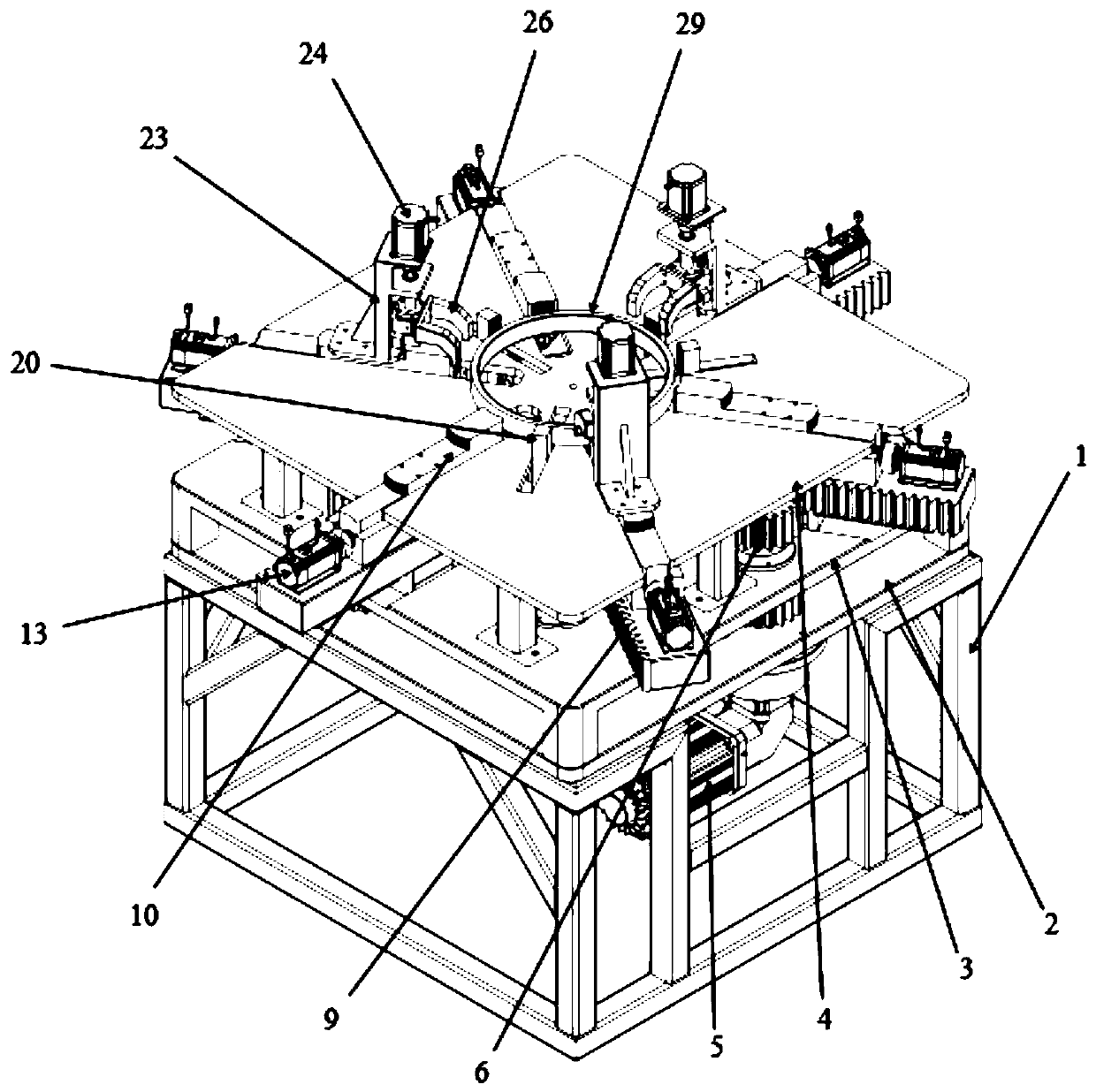

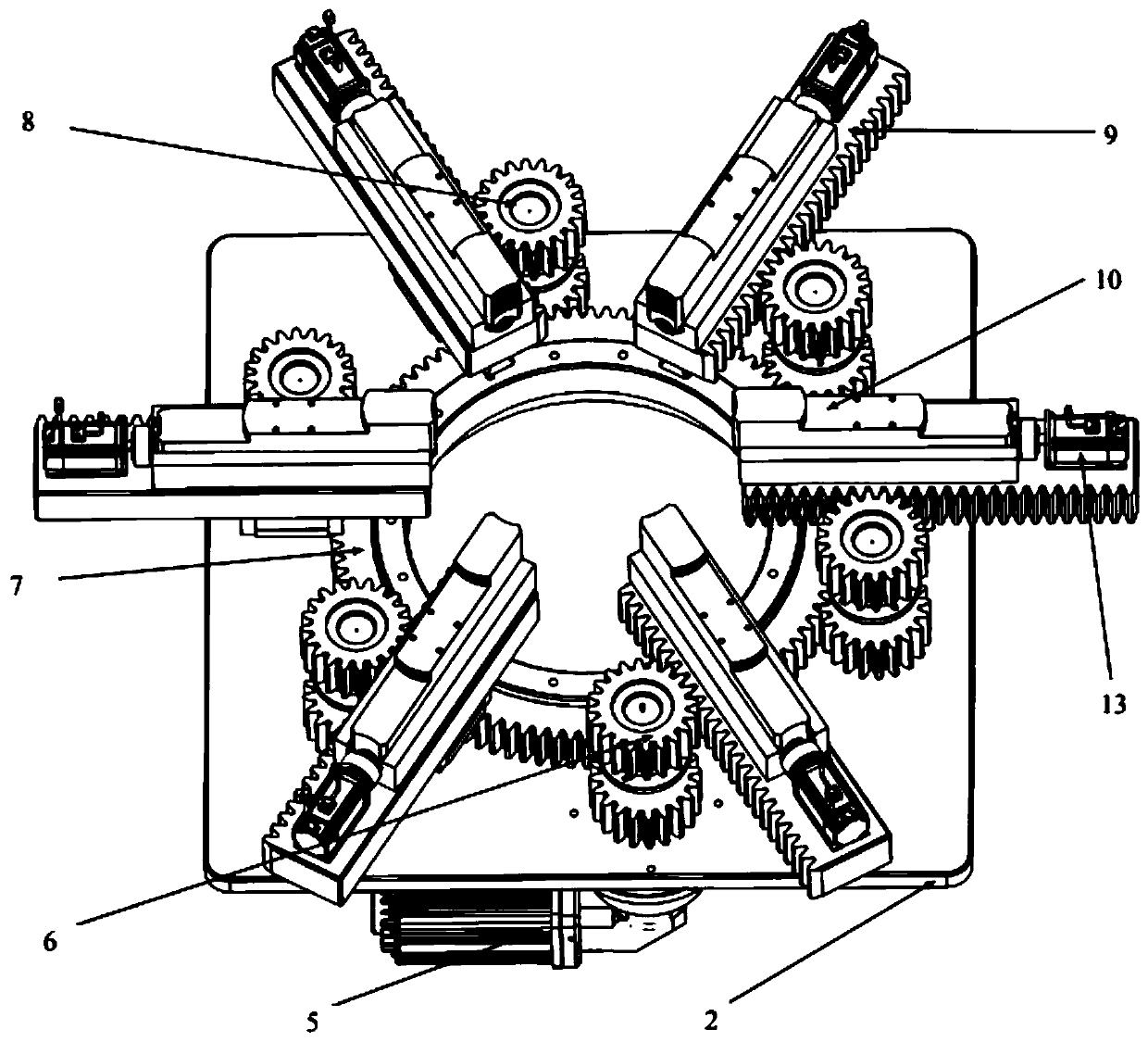

[0026] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1~5 As shown, a fast self-centering clamping device for a large bearing ring workpiece includes a base frame 1, a support table 4, a centering mechanism, a positioning and clamping mechanism, and a pressing mechanism;

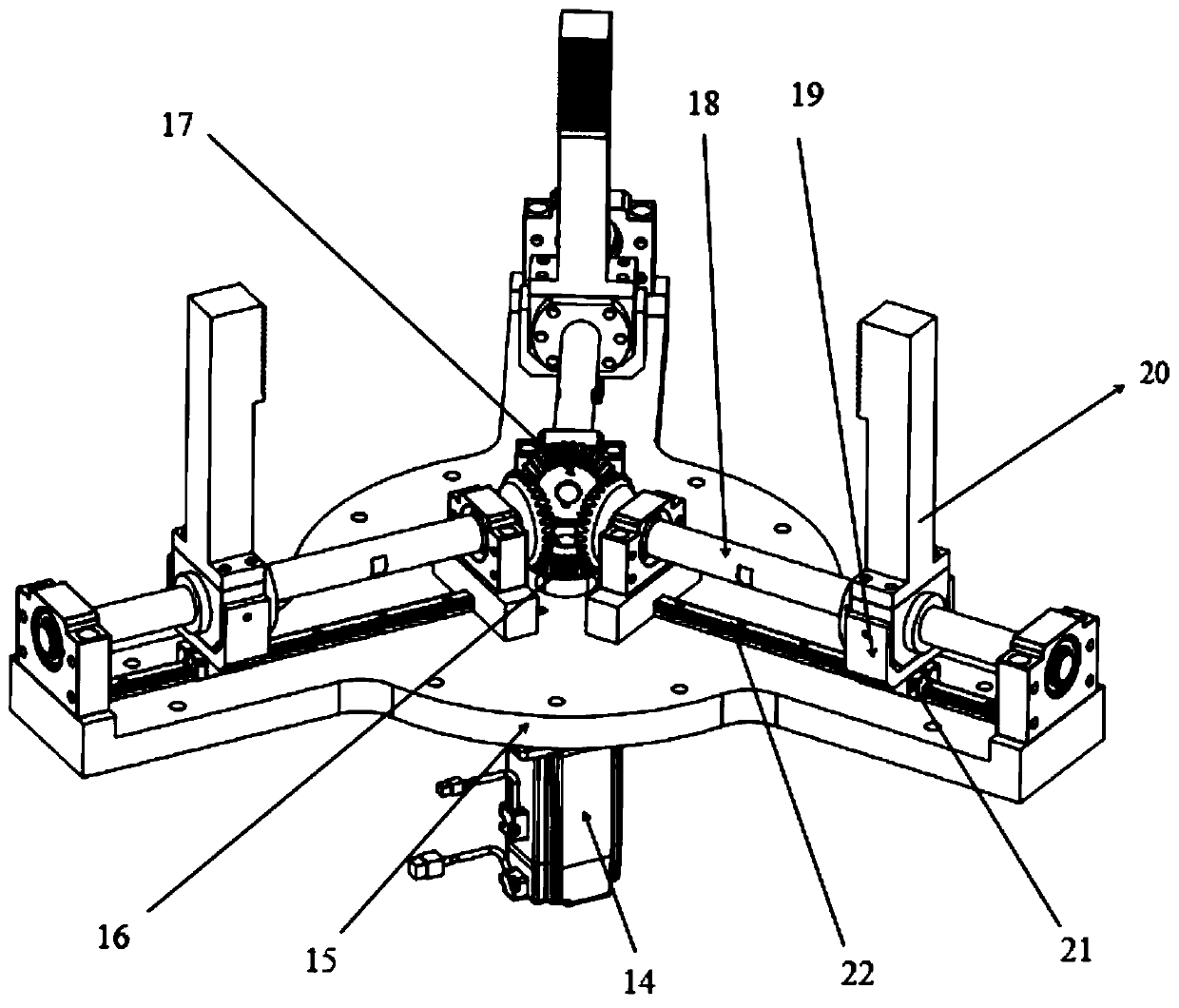

[0027] The centering mechanism includes a driving bevel gear 16, three driven bevel gears 17, a first servo motor 14, a first transmission screw 18, a moving slide 19, a centering claw 20, a first guide rail auxiliary slider 21 and the first guide rail auxiliary linear guide 22; the driving bevel gear 16 is installed in the center of the fixed base plate 15, the shaft end of the driving bevel gear 16 is downward and connected with the first servo motor 14, and the tooth end of the driving bevel gear 16 is connected with the first servo motor 14. The tooth ends of three driven bevel gears 17 mesh; the shaft ends of the driven bevel gears 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com