Anti-explosion patrolling task control method, storage medium and robot

A technology of inspection tasks and control methods, applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve the problems of instability, low sensitivity, small detectable range, etc., to improve the recognition accuracy and accuracy, improve the accuracy and Accurate, highly automated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

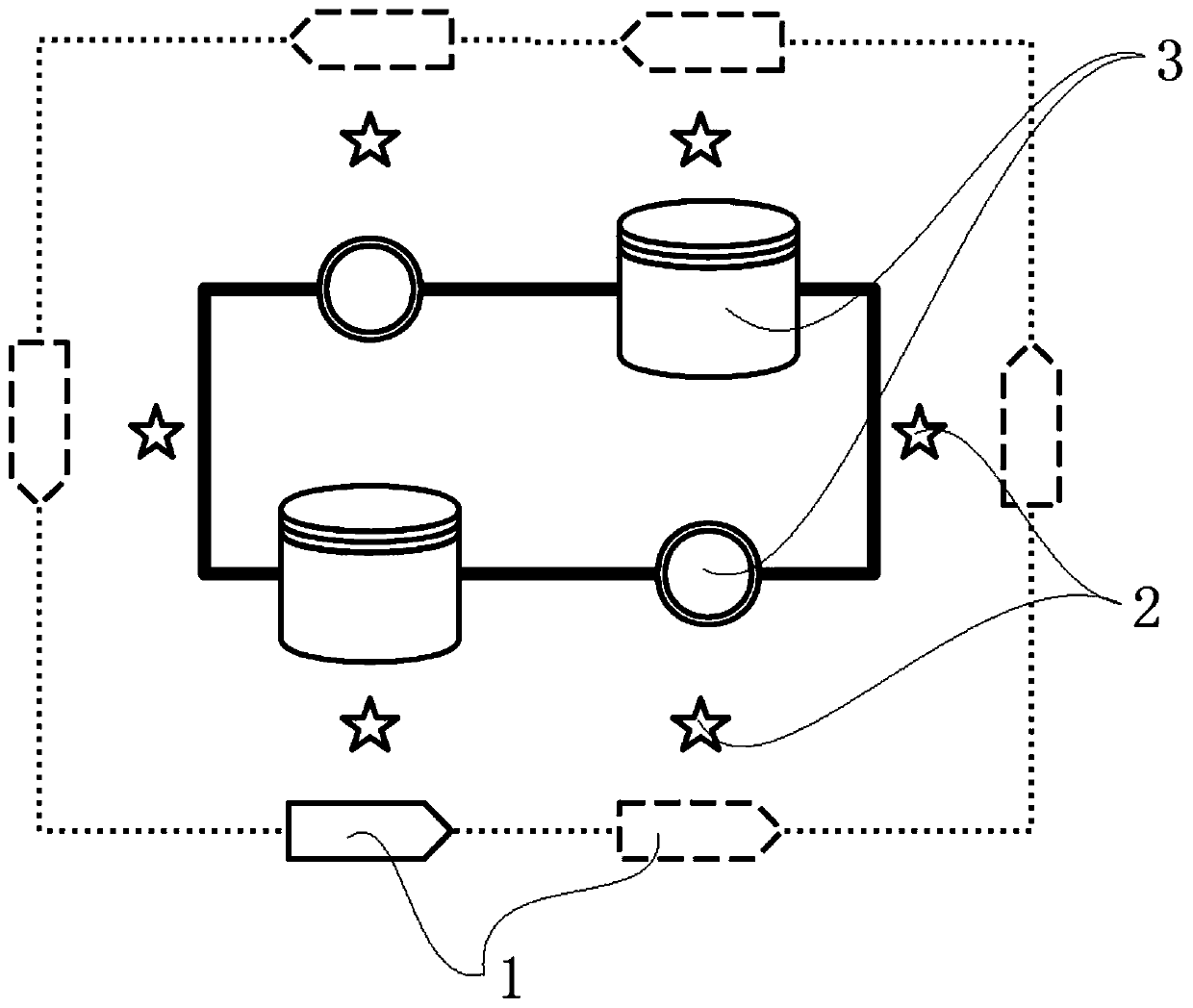

[0040] The invention discloses an explosion-proof inspection task control method. The explosion-proof inspection task is performed by navigating to a preset corresponding task point through a cruise unit. During the execution of the explosion-proof inspection task, corresponding task data will be obtained, and the obtained The task data is sent to the processor for data fusion processing, and the processor makes an instruction to continue performing the explosion-proof inspection task or report accident information according to the data fusion processing result.

[0041] In an embodiment of the present invention, the cruise unit includes an explosion-proof camera, a laser radar and an ultrasonic device. The explosion-proof camera shoots and recognizes obstacles and mission points, and adopts the explosion-proof camera to shoot and recognize obstacles and miss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com