A positioning device for a segment demoulding device

A technology of demolding device and positioning device, which is applied to unloading devices, ceramic molding machines, manufacturing tools, etc., can solve the problems of large gap between the positioning head and the positioning hole, easy damage, and damage to the positioning hole of the segment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

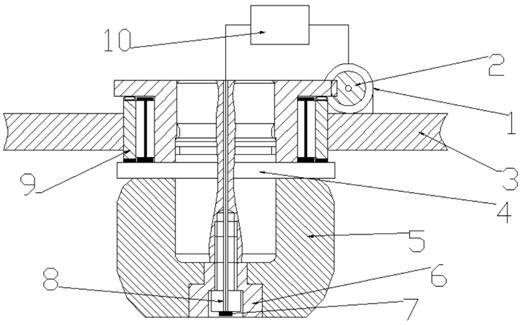

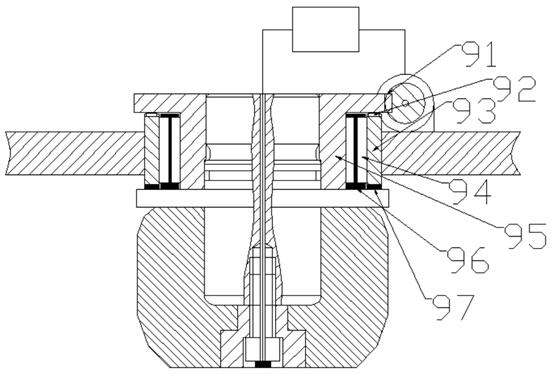

[0025] Such as figure 1 As shown, a positioning device of a segment demoulding device includes a motor 1, a worm 2, a rotating support member 9, a positioning head 4, a positioning rubber sleeve 5, a fixing head 6, a fixing screw 8, a control device 10 and a light sensor 7 .

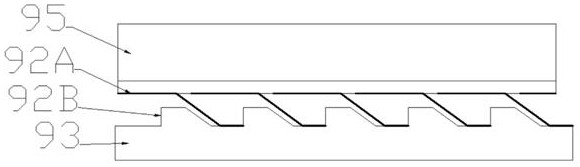

[0026] Wherein, the positioning head 4 is fixed on the panel 3 of the suction cup through the rotating support member 9, and the positioning head 4 includes a flange in the middle and cylindrical structures arranged on both sides of the flange. The cylinder structure on one side is set into the rotating support member 9, the outside of the cylinder structure on the other side is fitted with a positioning rubber sleeve 5, and one end of the cylinder on this side is also provided with a threaded hole, and the positioning rubber slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com