Book block flattening machine

A flattening machine and book block technology, applied in bookbinding flattening machines, book binding, printing, etc., can solve the problems of less force around, easy deformation, and affect the effect of flattening, and achieve uniform force , The flattening process is stable, and the effect of avoiding local stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

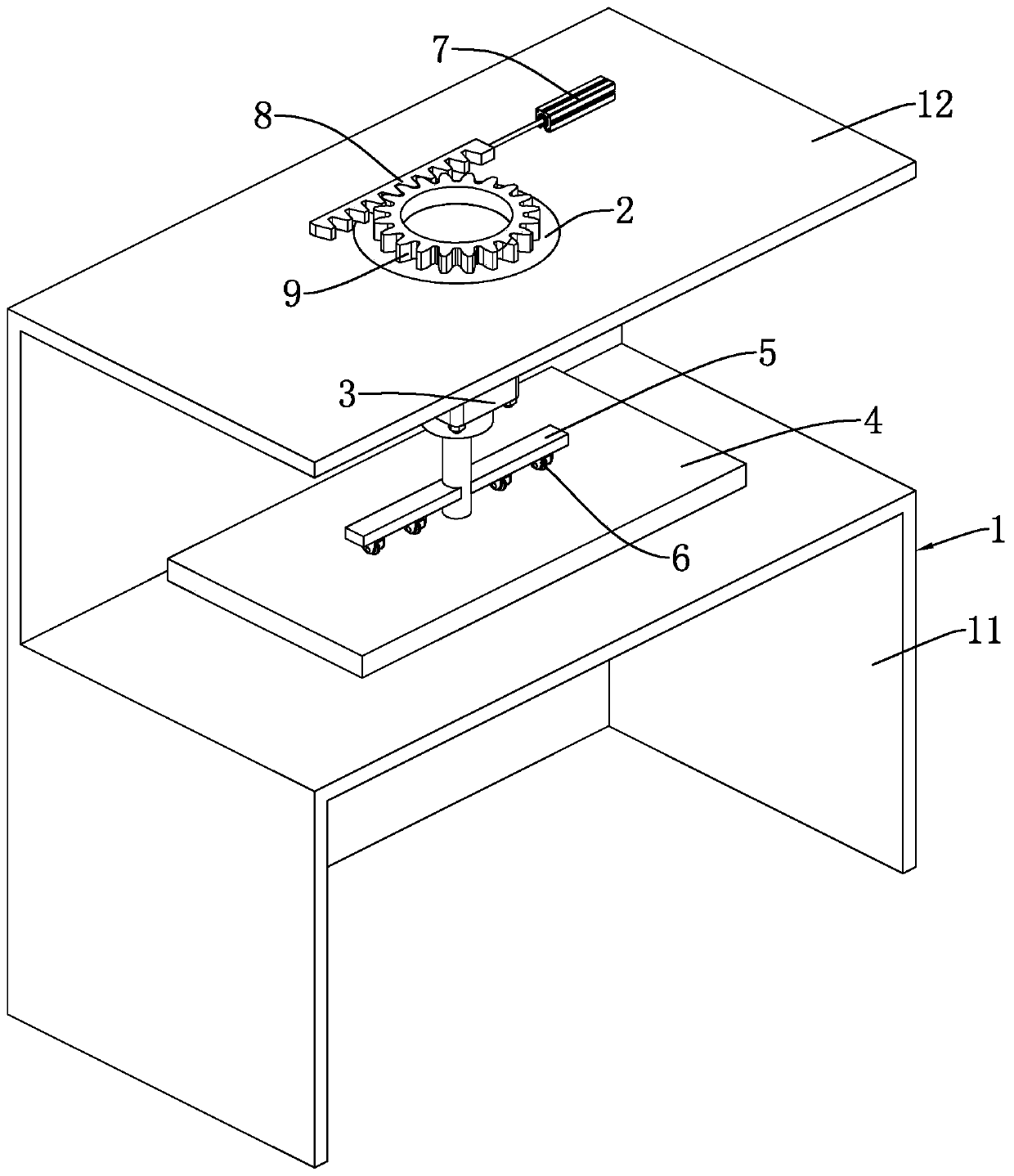

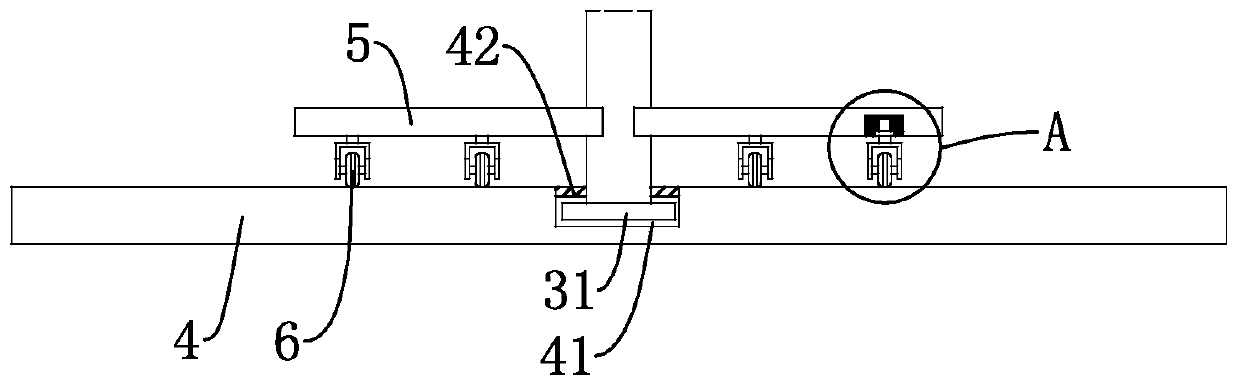

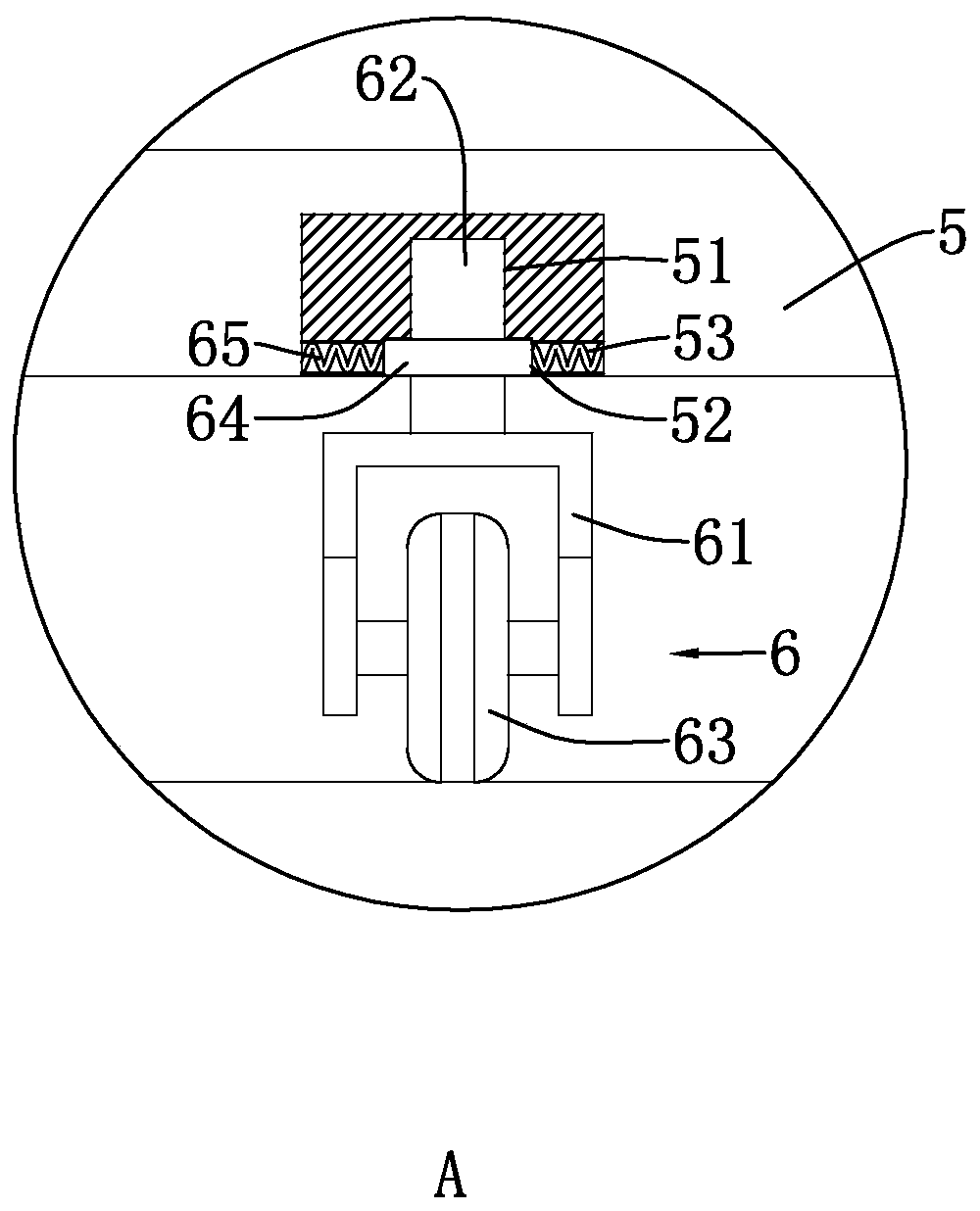

[0033] A book block flattening machine, such as figure 1 As shown, it includes a frame 1, a rotary table 2 rotatably installed on the frame 1, a hydraulic cylinder 3 fixedly connected to the rotary table 2 with the output end facing down, a pressing assembly rotatably mounted on the output end of the hydraulic cylinder 3, and settings. The adjustment assembly that drives the rotary table 2 to rotate on the frame 1, wherein the frame 1 includes two parts, the bottom frame 11 and the bracket 12, the bottom frame 11 is a standard rectangular frame, supported on the ground, and its top surface is closed, set as the machine The working surface of the frame 1; the support 12 is L-shaped, its vertical edge is vertically fixed on the working surface of the underframe 11, the horizontal edge is located at the top of the vertical edge, and is horizontally erected above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com