Stacking rack for building material management

A technology for stacking racks and materials, which is applied in the field of stacking racks for building materials management, can solve the problems that tubular building materials with different diameters cannot be stacked, and tubular building materials are prone to confusion and poor management, so as to reduce accidental risks and economic losses. The risk of accidental injury, the effect of easy handling and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

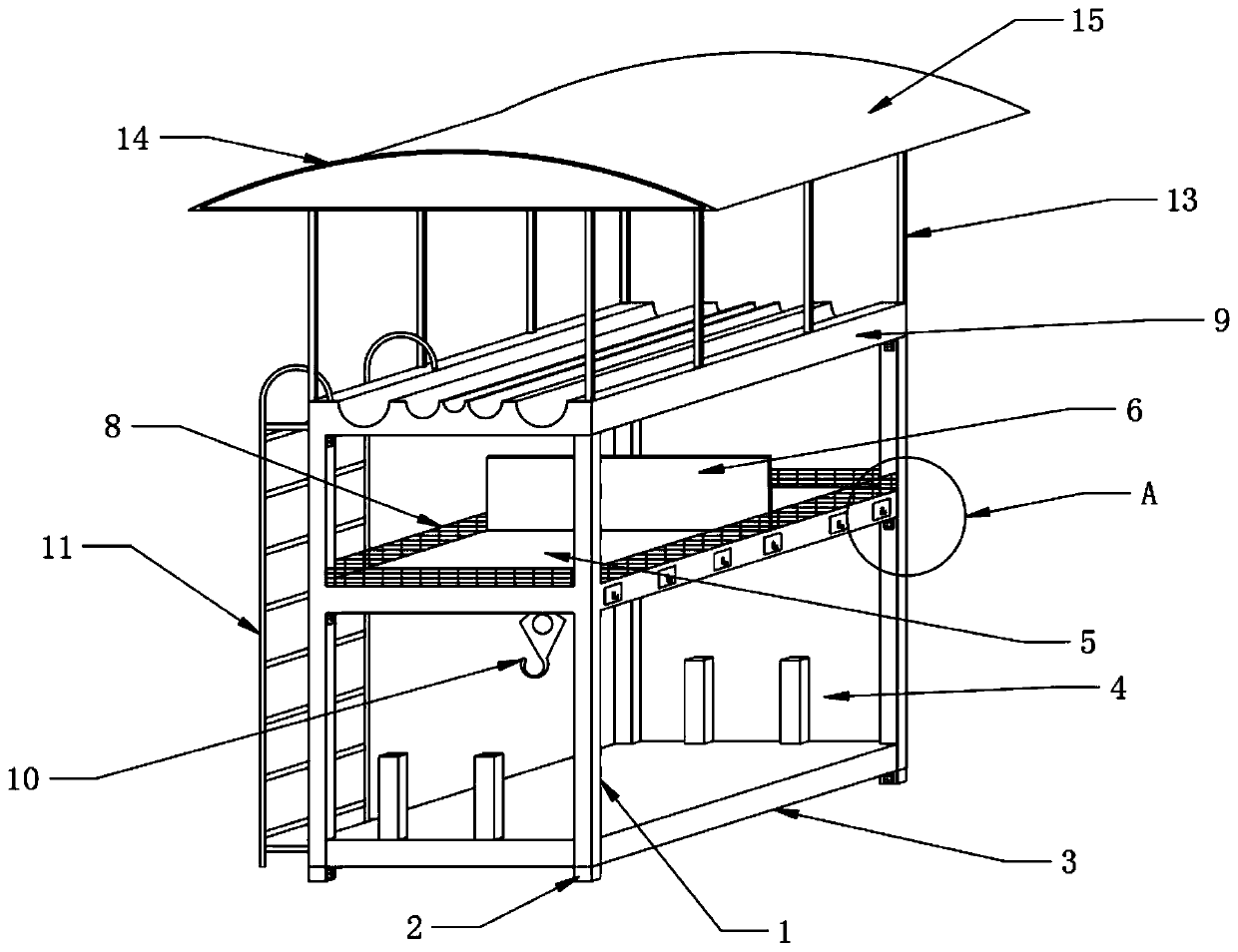

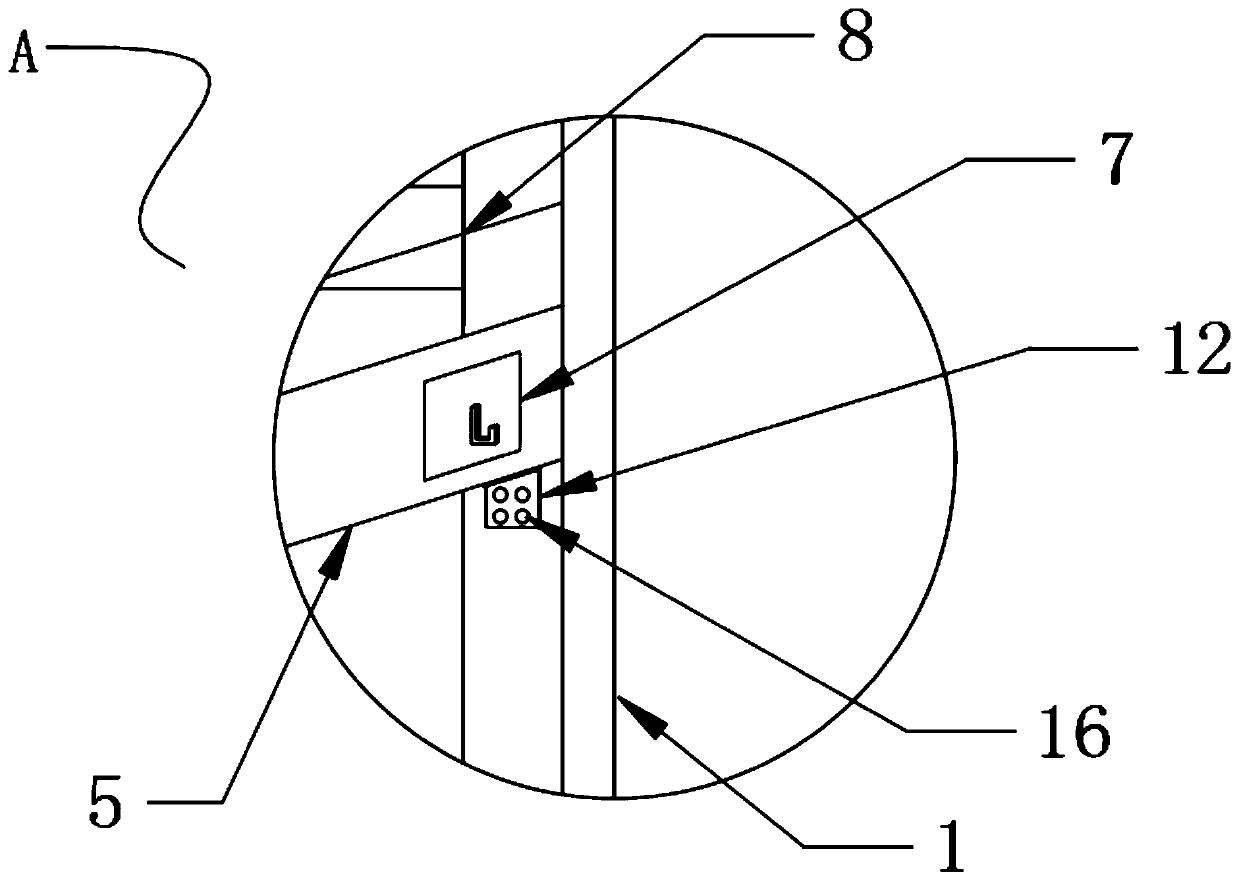

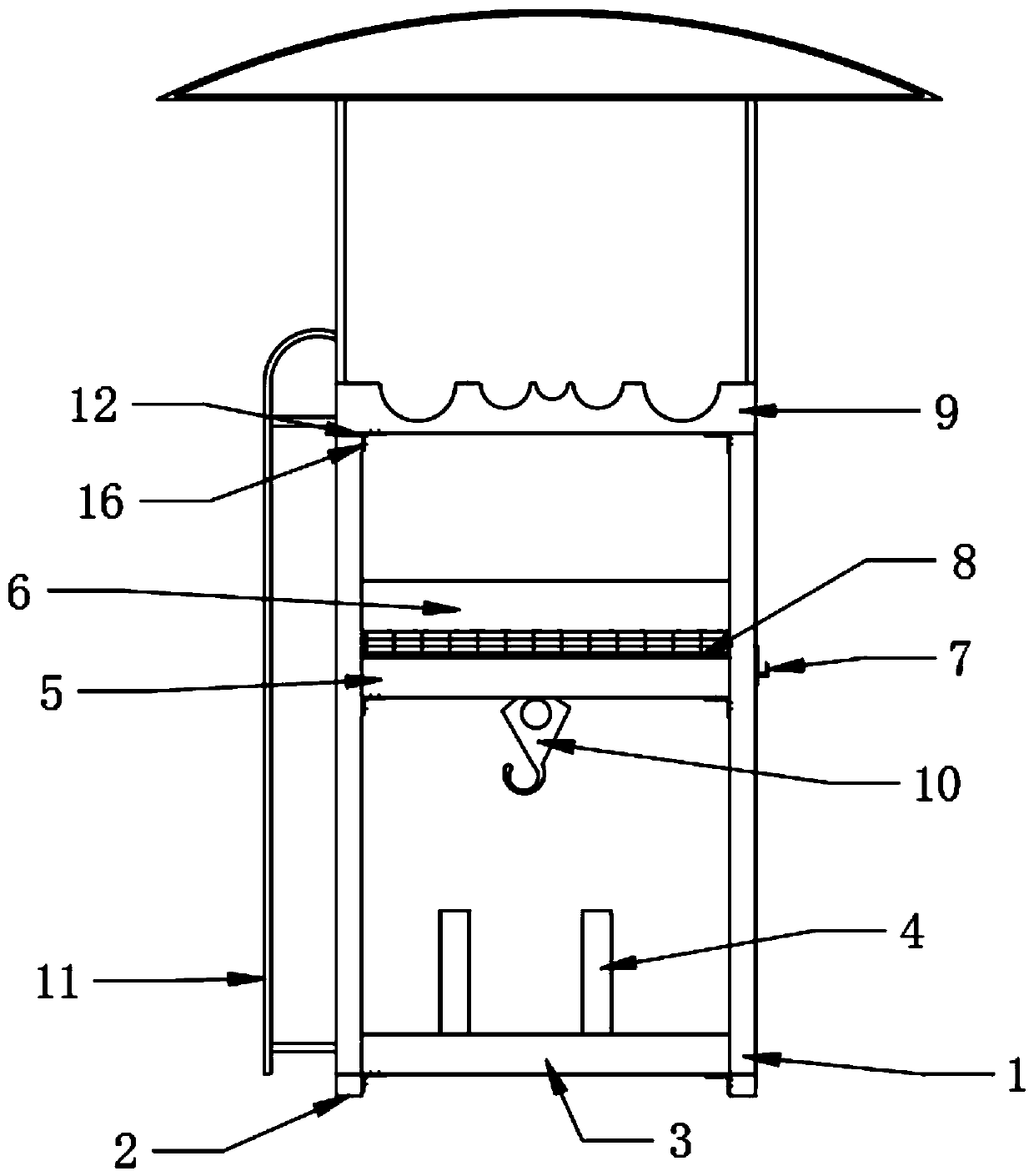

[0020] see Figure 1~4 , in an embodiment of the present invention, a stacking rack for building materials management includes four rectangular main poles 1, the bottom ends of the main poles 1 are connected with foot pads 2, and the lower ends of the four main poles 1 are connected by angle steel 12 and screws 16 are jointly fixedly connected to the No. 1 storage board 3, the middle parts of the four main poles 1 are jointly fixedly connected to the No. 2 storage board 5 by angle steel 12 and screws 16, and the tops of the four main poles 1 are connected by angle steel 12 and screws 16 Jointly fixedly connect the pipe fixing seat 9, the two sides of the top of the No. 1 storage board 3 are fixedly connected with four separation piles 4 by welding, the middle part of the No. 2 storage board 5 is provided with a partition plate 6 and fixed by welding, and the two sides of the No. 2 storage board 5 A grid net 8 is provided, and is fixed to the No. 2 storage board 5 by welding un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com