Organic material storage tank VOCs zero emission storage system and method

A technology for organic materials and storage systems, applied in the directions of containers, packaging, transportation and packaging, can solve problems such as environmental pollution, increase storage costs, hidden safety hazards, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

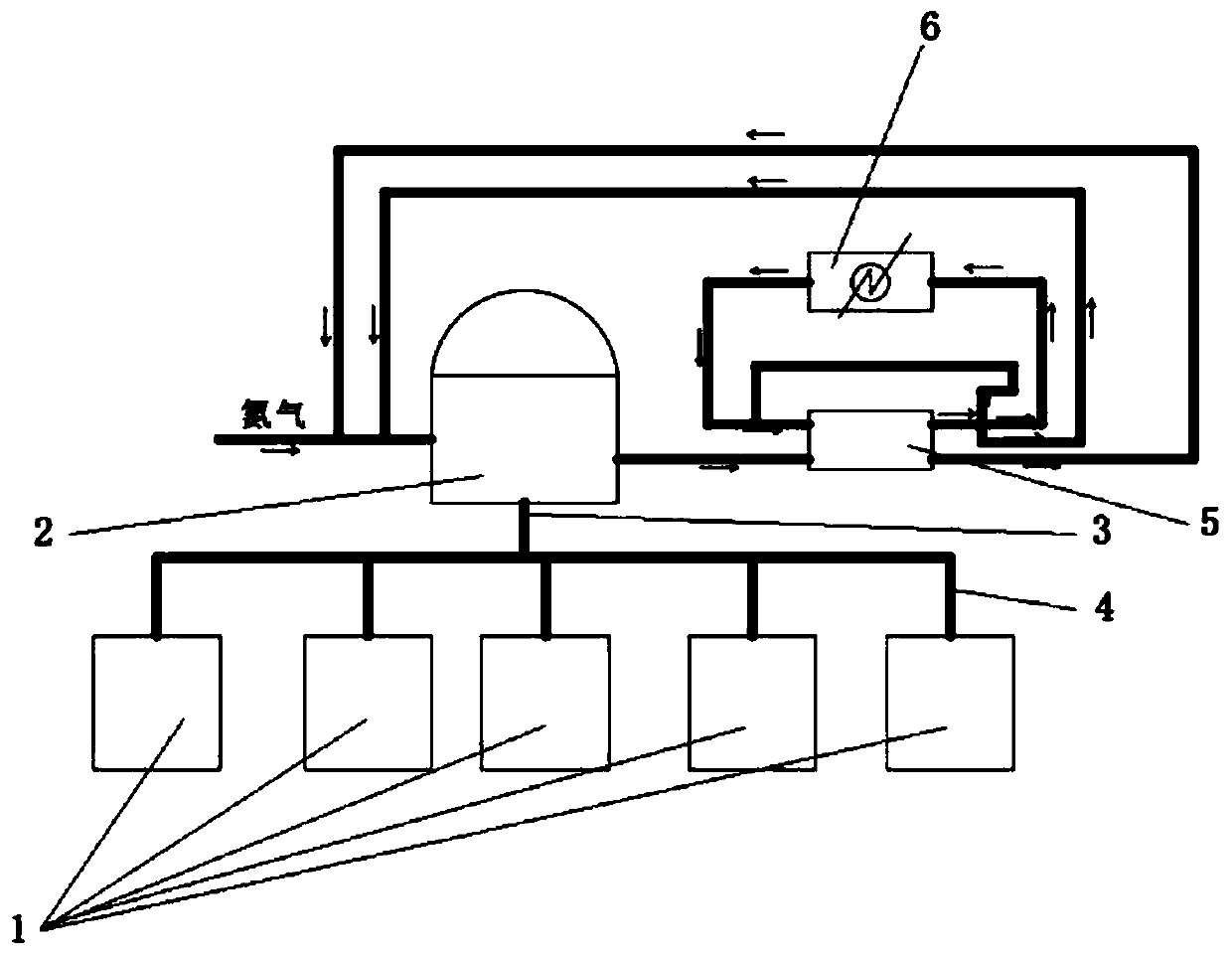

[0032] A VOCs zero-emission storage system for organic material storage tanks, comprising N storage tanks 1, a dry gas cabinet 2, a pressure balance main pipe 3, N pressure balance branch pipes 4, and a purification recovery device. The dry gas cabinet 2 has a high position limiting device and a pressure safety valve. The storage tank 1 is provided with a liquid level gauge for displaying its liquid level. The storage tank 1 has a feed port, a discharge port and an exhaust port. N storage tanks 1 pass through the pressure balance branch pipe 4 and the pressure balance main pipe 3. One end is connected, and the other end of the pressure balance main pipe 3 is connected with the dry gas cabinet 2. The dry gas cabinet 2 has a pressure balance pipe interface, a recycle gas inlet and a recovery gas outlet. A nitrogen replenishment pipe can also be externally connected to the connecting pipe of the circulating gas inlet.

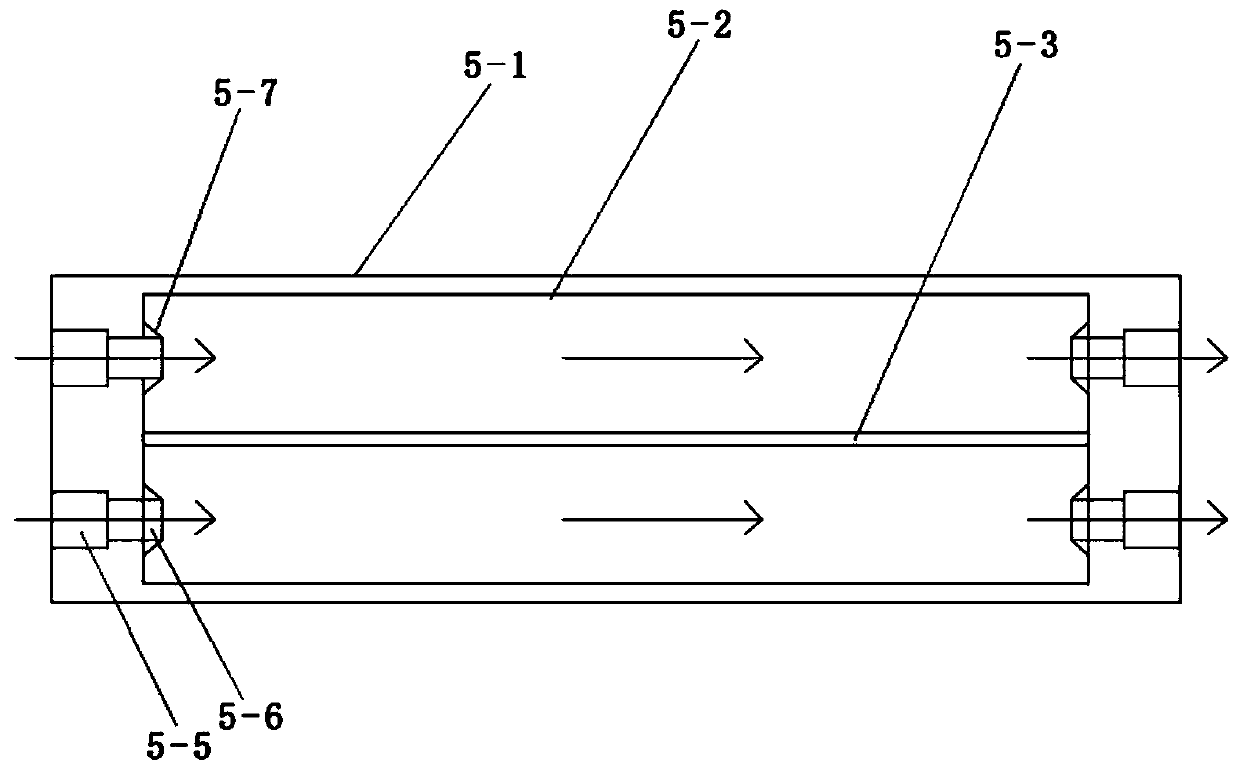

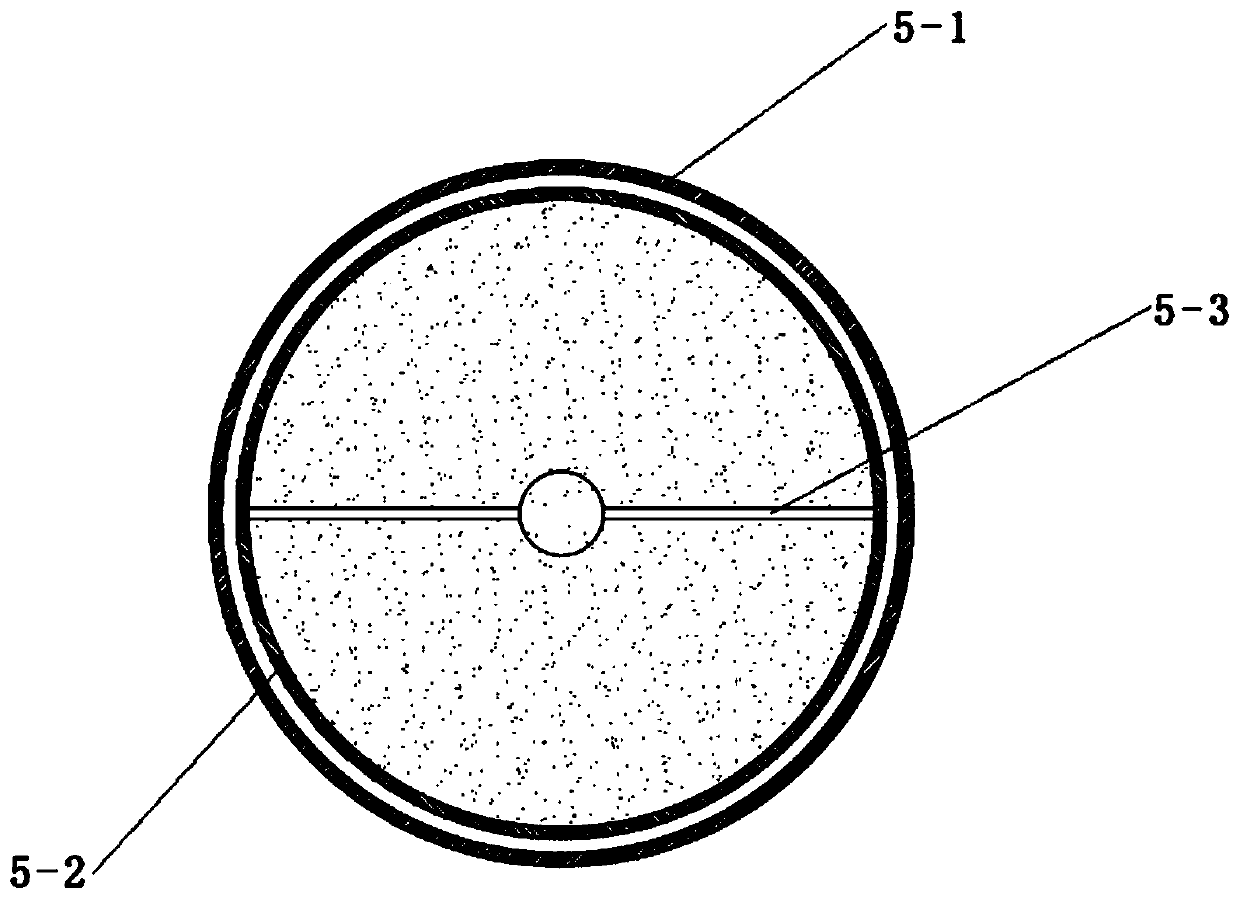

[0033] The purification recovery device includes an adsorp...

Embodiment 2

[0039] A zero-emission storage method for VOCs in an organic material storage tank:

[0040] S1. Sealed connection: connect the storage tank to the pressure balance main pipe through the pressure balance branch pipe, and then connect the pressure balance main pipe to the dry gas cabinet;

[0041] S2. Initial phase setting: Set the constant pressure value of the dry-type gas holder according to the storage capacity of the storage tank. When the storage tank is completely empty, the internal pressure connected between the storage tank and the dry-type gas holder is at the lowest position, which is the initial position , the gauge pressure inside the dry-type gas holder is zero at this time;

[0042] S3. Gas protection: before the storage tank enters the material, the internal air is replaced by a circulating gas discharge system, so that the inner cavity of the storage tank is completely filled with circulating gas, and the inner cavity of the tank forms an oxygen-free environme...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap