Airy craft beer with high clarity and production process thereof

A production process and clarity technology, applied in the field of ale craft beer and its production process, can solve the problems of dull appearance, unpalatable taste, low turbidity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

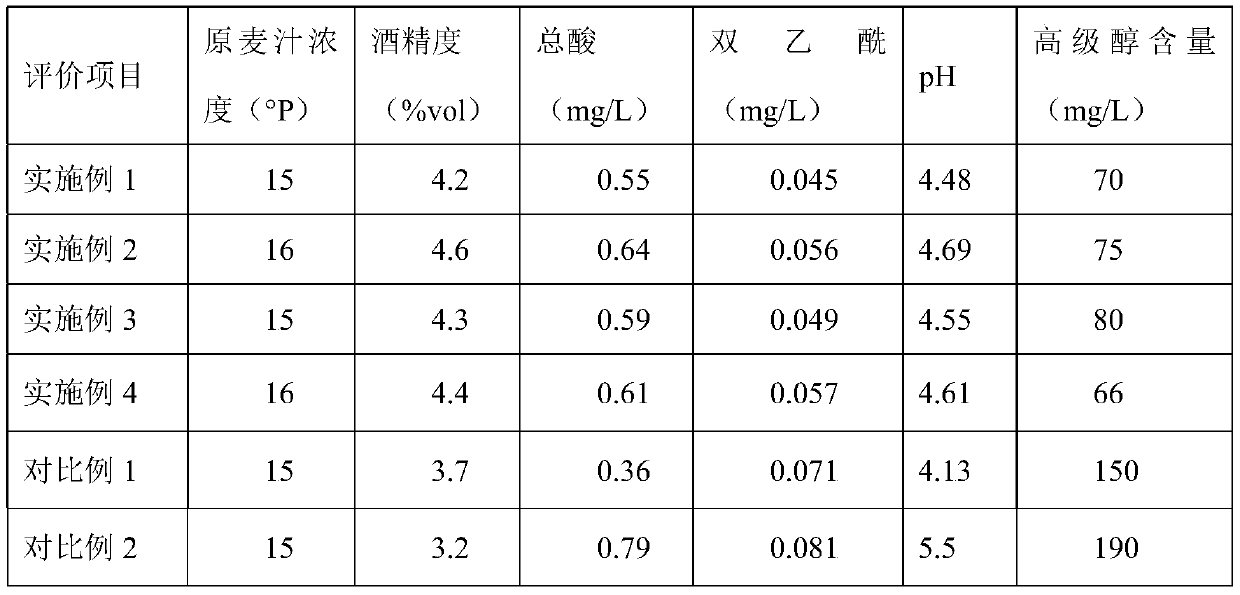

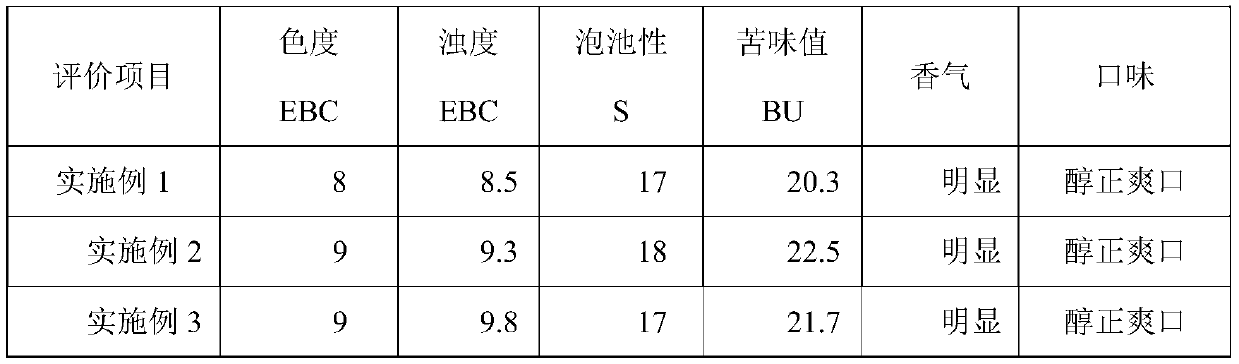

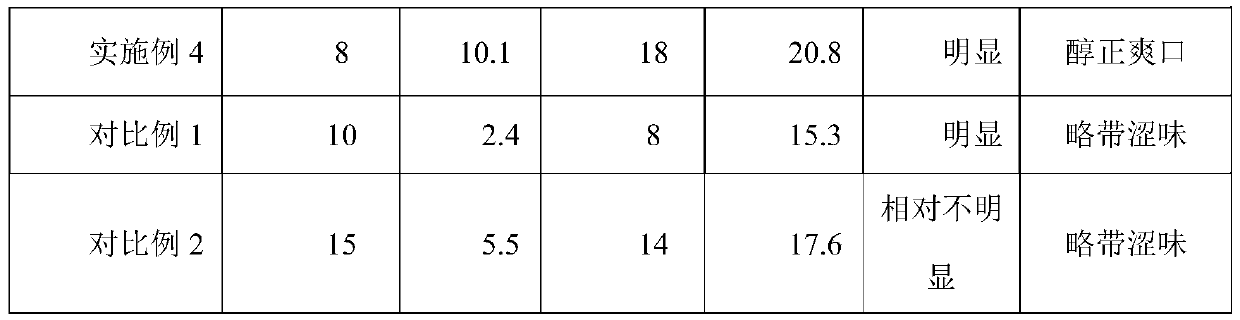

Examples

Embodiment 1

[0064] A craft ale beer with high clarity, in parts by weight, comprising the following raw materials:

[0065] 66 parts of malt, 1.2 parts of hops, 0.3 parts of ale yeast;

[0066] The malt, in parts by weight, includes the following raw materials: 20 parts of barley malt, 20 parts of wheat malt, 10 parts of caramel malt, 10 parts of Victoria malt, 3 parts of chocolate malt, and 3 parts of Munich malt;

[0067] The hops, in parts by weight, include the following components: 0.2 parts of Cascade hops, 0.2 parts of Magnummen hops, 0.2 parts of Century hops, 0.2 parts of Chinook hops, 0.2 parts of Czech Saaz hops, crystal 0.2 parts of granular hops.

[0068] A kind of production technology of ale craft beer with high clarity, comprising the following steps:

[0069] S1 Material preparation and saccharification: Grind the malt, pour it into the saccharification tank, add mountain spring water 3 times the weight of the malt, heat to 50°C, keep it for 10 minutes, then raise the t...

Embodiment 2

[0075] A craft ale beer with high clarity, in parts by weight, comprising the following raw materials:

[0076] 100 parts of malt, 3 parts of hops, 0.5 parts of ale yeast;

[0077] The malt, in parts by weight, includes the following raw materials: 30 parts of barley malt, 30 parts of wheat malt, 15 parts of caramel malt, 15 parts of Victoria malt, 5 parts of chocolate malt, and 5 parts of Munich malt;

[0078] The hops, in parts by weight, include the following components: 0.5 parts of Cascade hops, 0.5 parts of Magnummen hops, 0.5 parts of Century hops, 0.5 parts of Chinook hops, 0.5 parts of Czech Saaz hops, crystal Granular hops 0.5 part.

[0079] A kind of production technology of ale craft beer with high clarity, comprising the following steps:

[0080] S1 material preparation and saccharification:

[0081] Crush the malt, pour it into the saccharification tank, add mountain spring water 3-4 times the weight of the malt, heat to 55°C, keep it for 10 minutes, then rais...

Embodiment 3

[0087] A craft ale beer with high clarity, in parts by weight, comprising the following raw materials:

[0088] 80 parts of malt, 2 parts of hops, 0.4 parts of ale yeast;

[0089] The malt, in parts by weight, includes the following raw materials: 25 parts of barley malt, 25 parts of wheat malt, 11 parts of caramel malt, 11 parts of Victoria malt, 4 parts of chocolate malt, and 4 parts of Munich malt;

[0090] The hops, in parts by weight, include the following components: 0.3 parts of Cascade hops, 0.3 parts of Magnummen hops, 0.3 parts of Century hops, 0.3 parts of Chinook hops, 0.4 parts of Czech Saaz hops, crystal Granular hops 0.4 parts.

[0091] A kind of production technology of ale craft beer with high clarity, comprising the following steps:

[0092] S1 material preparation and saccharification:

[0093] Crush the malt, pour it into the mash tank, add mountain spring water 3.5 times the weight of the malt, heat it to 53°C, keep it for 10 minutes, then raise the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com