A warping machine for preventing warp damage

A warping machine and warp yarn technology, applied in the textile field, can solve problems such as yarn and equipment damage, shutdown, safety hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

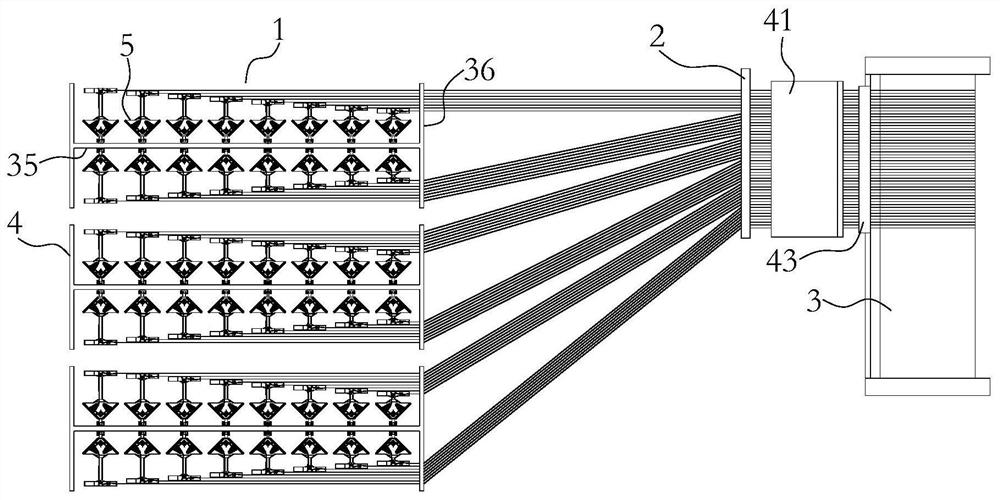

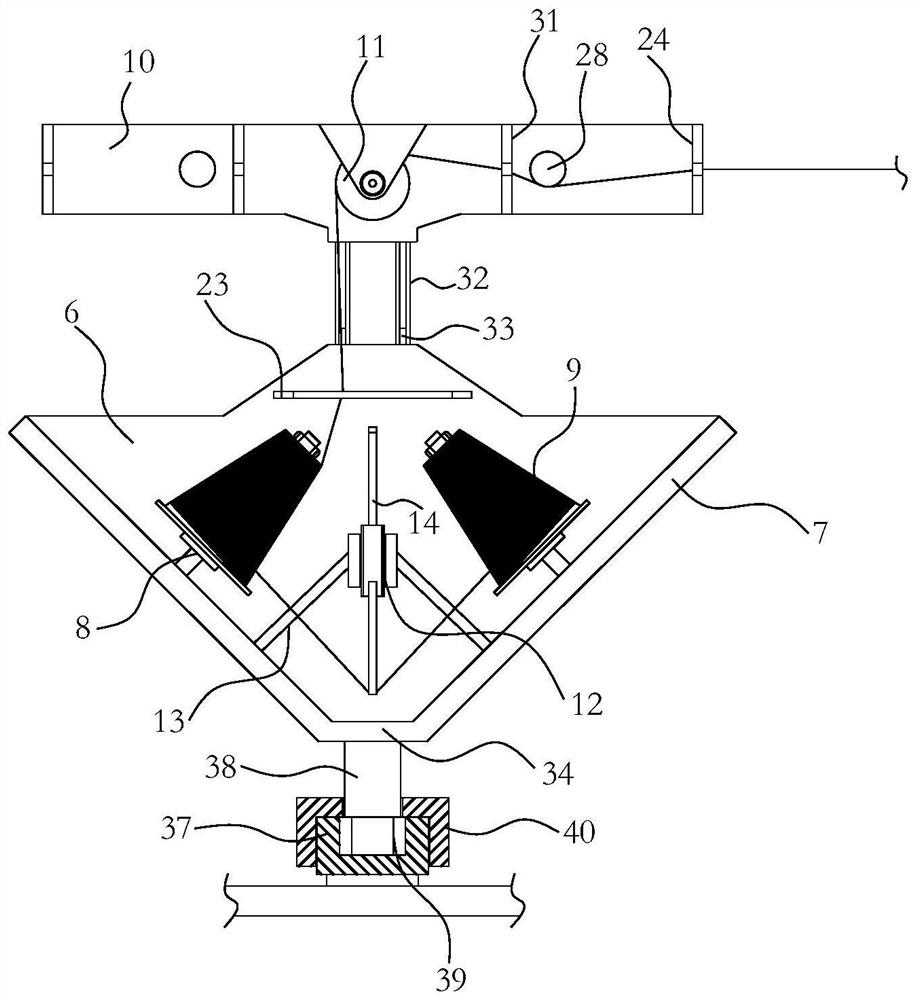

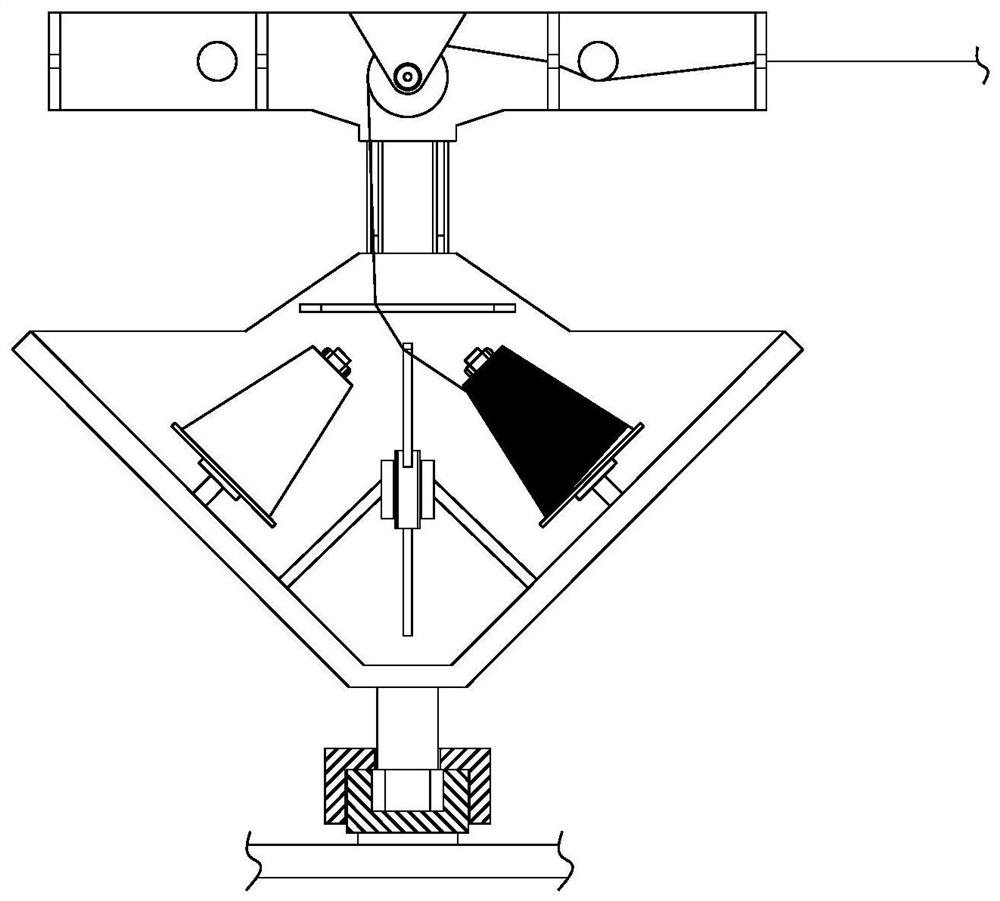

[0036] Such as Figure 1-15A warping machine shown to prevent warp damage is the same as a traditional warping machine in that the present invention also includes a creel 1 , a yarn collecting plate 2 and a warping machine main body 3 arranged in sequence. The creel 1 is used to install the yarn bobbin and is used for unwinding the bobbin; the yarn collecting plate 2 is used to guide the warp yarn unwound from the creel 1 so that it can enter the main body of the warping machine 3 normally The swimming device 43 can move along the length direction of the warp shaft of the warping machine main body 3, so that the warp yarns can be wound on the warp shaft in an orderly manner.

[0037] In combination with the various problems mentioned in the background technology, the present invention improves the existing warping machine in many aspects, so as to improve the overall working performance of the warping machine:

[0038] First, from the improvement of the creel structure:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com