Machine head structure of cylinder fabric joining machine

A technology of cloth splicing machine and machine head, which is applied in the direction of cloth feeding mechanism, sewing machine components, program-controlled sewing machines, etc., can solve the problems of unstable product qualification rate, increase the work intensity of workers, reduce the work efficiency of workers, etc., and achieve savings. Manpower, realize automatic operation, avoid the effect of manual handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

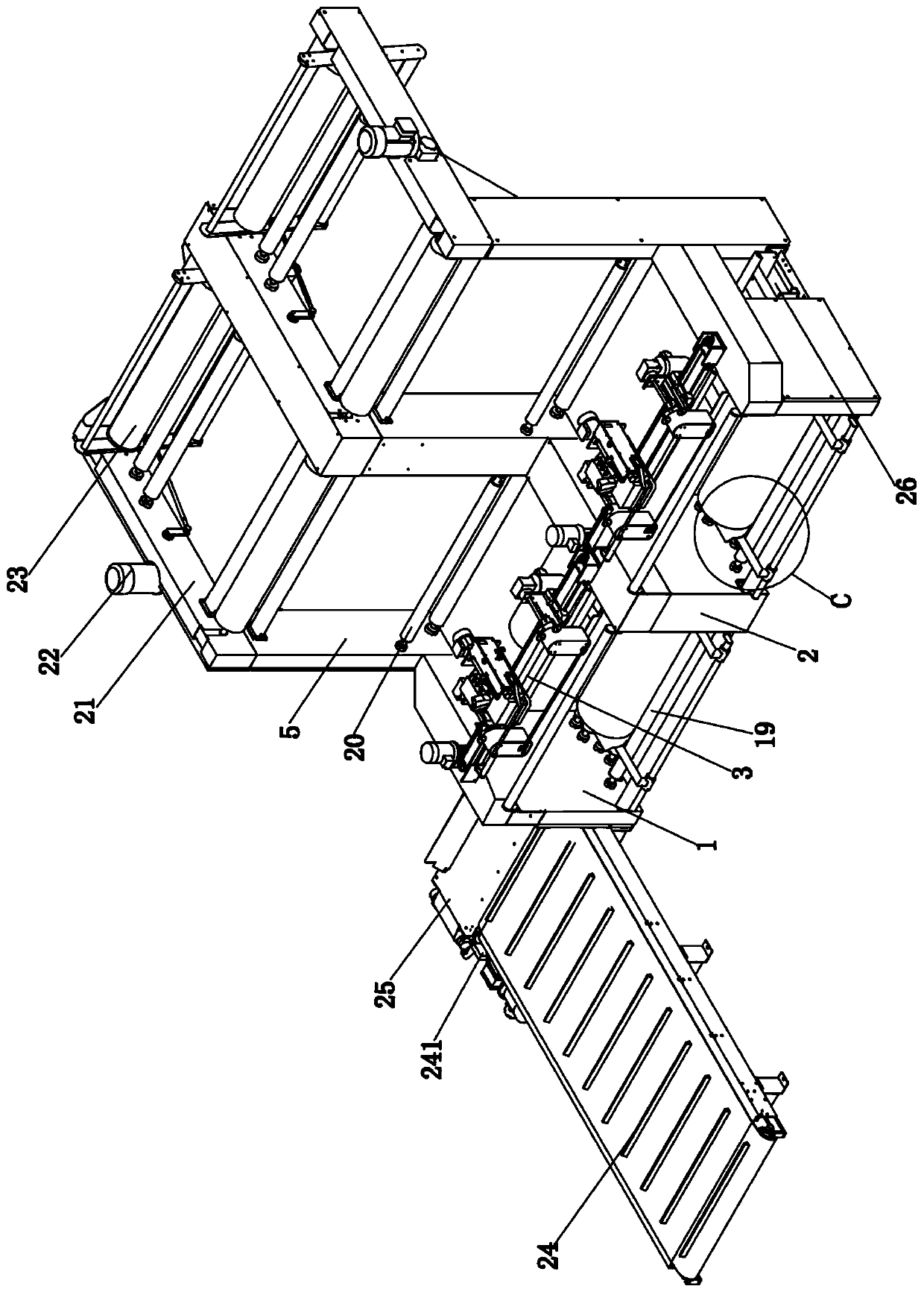

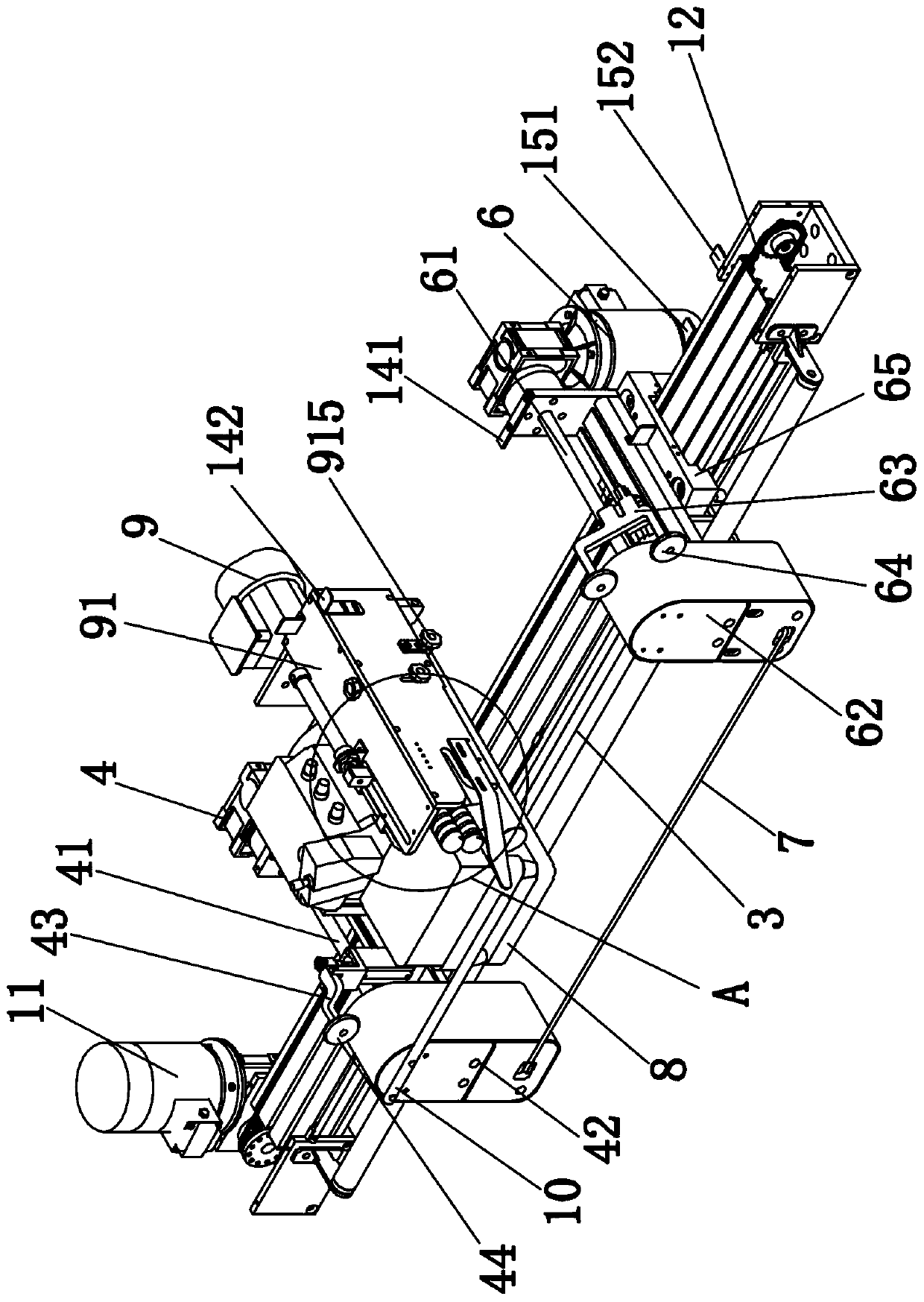

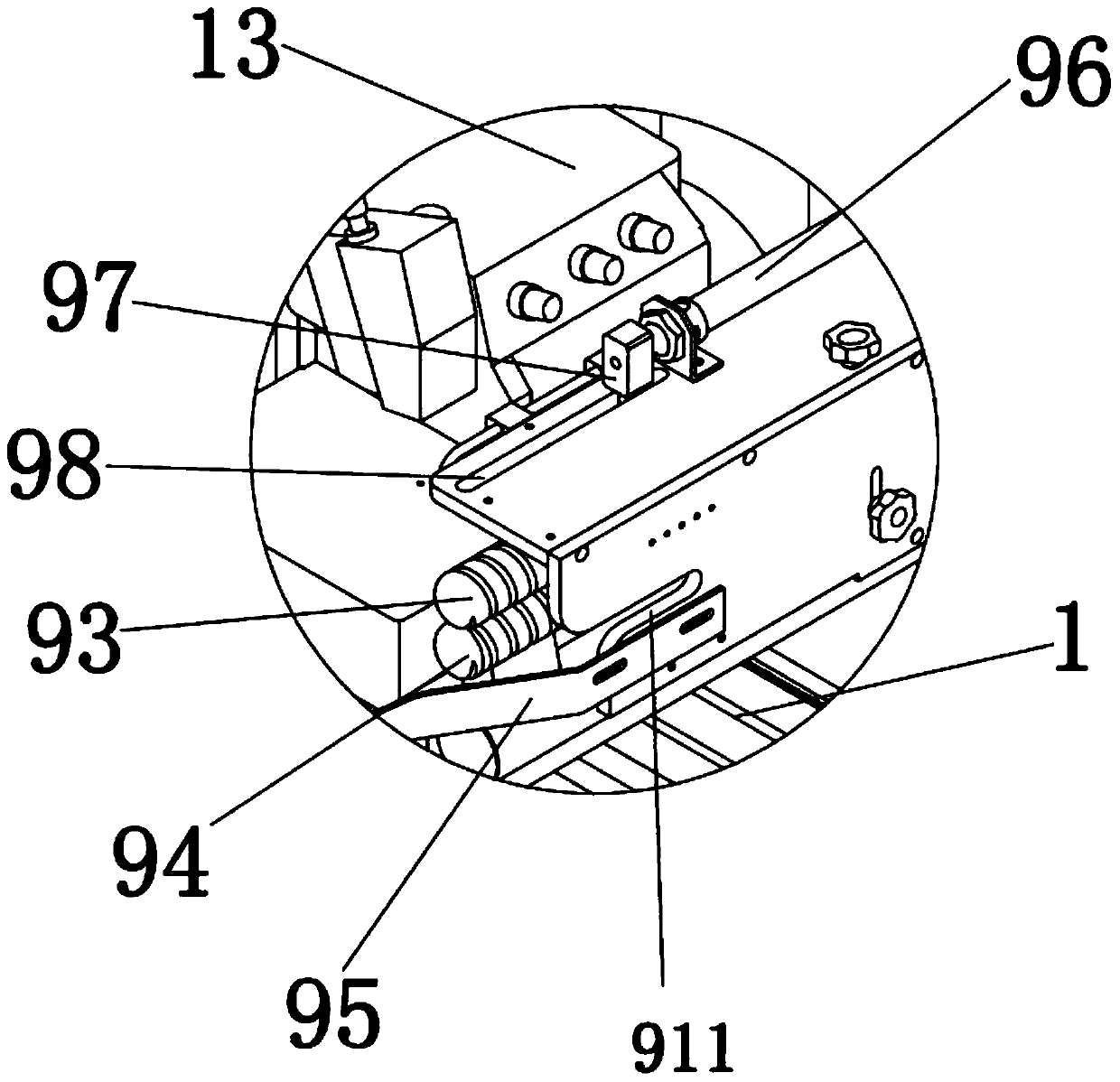

[0024] Embodiment: a kind of machine head structure of cylinder cloth splicing machine, as Figure 1-Figure 9Shown, comprise front vehicle frame 1 and rear vehicle frame 5, rear vehicle frame 5 is fixedly connected on the top of front vehicle frame 1 rear end, the left side of front vehicle frame 1 is provided with storage cloth conveyor belt 24, and the cloth storage conveyor belt 24 The rear end is provided with a cloth feeding conveyor belt 25, and the cloth storage conveyor belt 24 is provided with a first sensor 241 near one end of the cloth feeding conveyor belt 25, and two groups of cloth turning conveying mechanisms 26 are arranged on the rear side of the bottom of the front frame 1. The front side of the middle part of the cloth turning conveyor mechanism 26 is provided with a pneumatic pushing device 261, the right end of the cloth feeding conveyor belt 25 is connected with the cloth turning conveying mechanism 26, and the right end top of the cloth feeding conveyor b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com