Swing type compact snow removal roller brush

A compact, swing-type technology, applied in snow surface cleaning, cleaning methods, construction, etc., can solve the problems of narrow snow throwing space, complex control system, and uncompact structure, and achieve flexible control, reduced linkage mechanism, and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

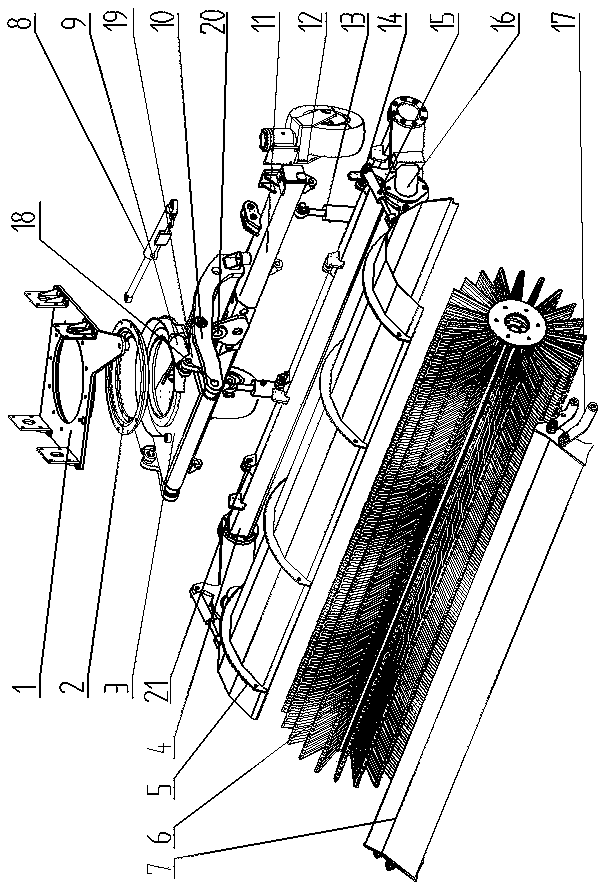

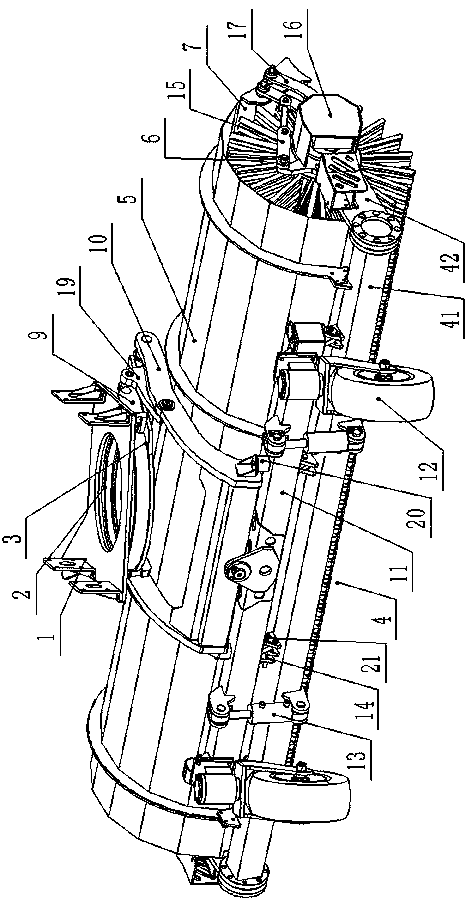

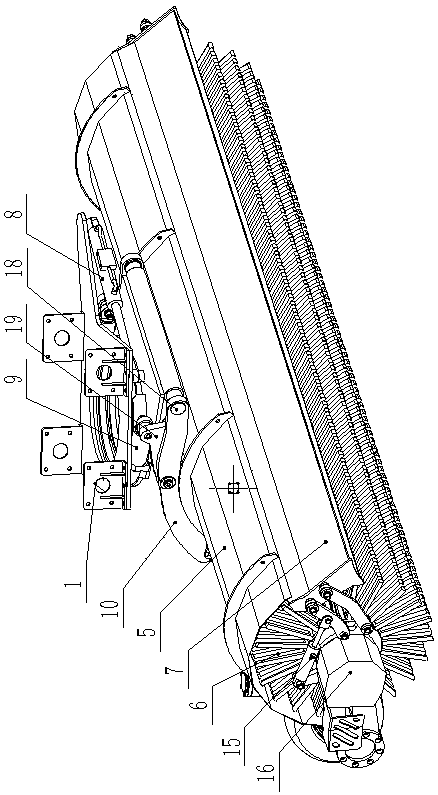

[0046] Such as Figure 1-6 Commonly shown, the present invention provides a swinging compact snow removal roller brush, comprising a horizontal swing mechanism, a vertical swing mechanism, and a brush shaft swing mechanism; the vertical swing mechanism is hinged on the horizontal swing mechanism; the brush shaft swings The mechanism is hinged on the vertical swing mechanism, and the brush shaft swing mechanism is connected with a hydraulic motor to drive the brush shaft assembly 6 to rotate, and the road snow is removed by the rotation of the brush shaft assembly 6 .

[0047]The horizontal swing mechanism is used to swing the roller brush at a certain angle in the horizontal direction to sweep the snow to both sides of the vehicle; the horizontal swing mechanism includes a slewing bearing 2, which is a standard part, and the slewing bearing 2 is provided with an outer disk and an inner disk that rotate with each other, and the outer disk of the slewing bearing 2 is fixedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com