Vertical well casing outer sand loss profile prediction and high-saturation gravel filling construction method

A gravel filling, vertical well technology, applied in earthwork drilling, wellbore/well components, image data processing, etc., can solve problems such as poor comprehensive effect and general construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

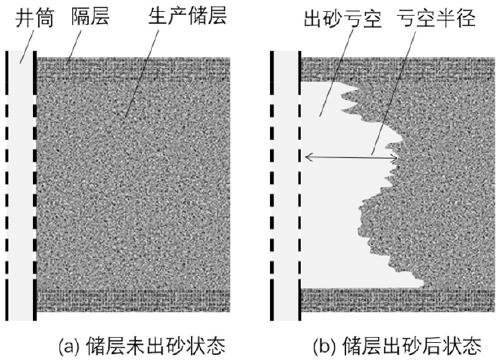

[0110] The construction method of gravel packing outside the vertical well pipe is applied to unconsolidated sandstone sand producing oil and gas reservoirs, and specifically includes the following steps:

[0111] (1) Prediction of longitudinal sand production profile deficit in production layers outside the vertical well pipe: use the above prediction method to predict the longitudinal sand production profile deficit of the production layer outside the vertical well pipe, and make a longitudinal sand production deficit profile;

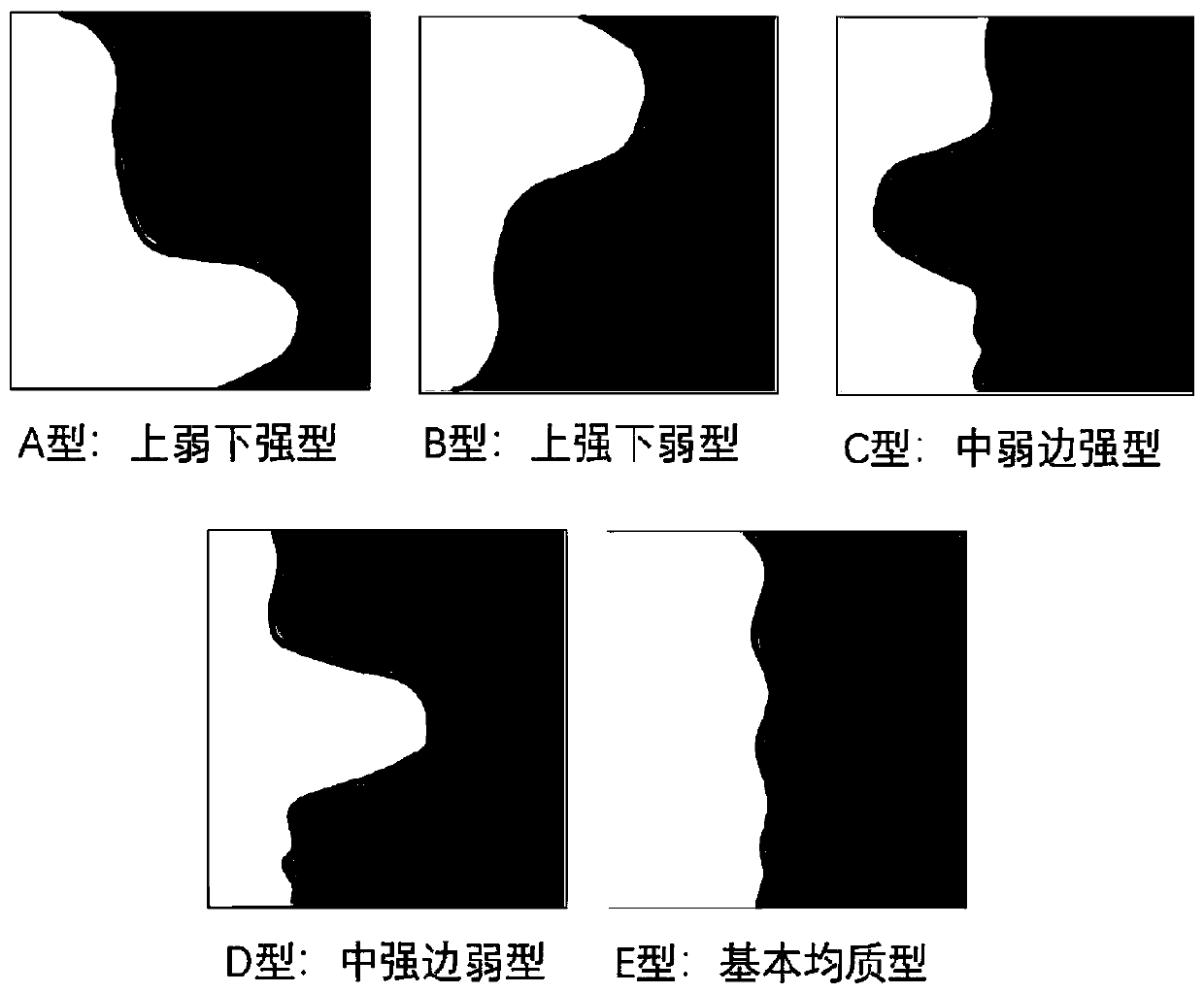

[0112] (2) Discrimination of heterogeneous mode of sand production deficit profile: according to the longitudinal sand production deficit profile obtained in step (1), the longitudinal distribution law of sand production profile deficit is analyzed, and it is judged that it belongs to or is close to type A: the weak deficit in the upper part and the weak deficit in the lower part The up-weak-down-strong pattern formed by strong shortfalls, see figur...

Embodiment 2

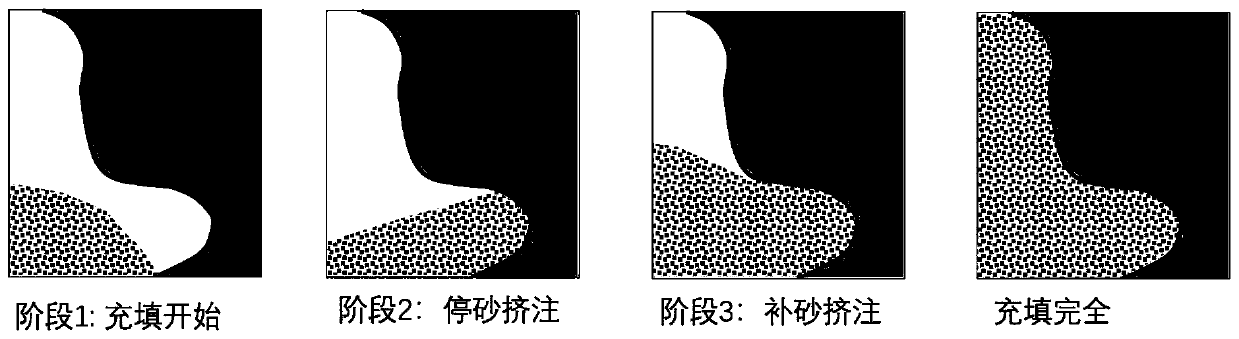

[0123] According to the discrimination of the heterogeneity mode of the sand production deficit profile, it is judged that it belongs to or is close to type B: a strong upper part and a weaker lower part composed of a strong deficit in the upper part, see figure 2 ; According to the class division of displacement and sand ratio described in embodiment 1, in combination with the characteristics of the above-mentioned B-type heterogeneous model, design the following staged pump injection construction procedures:

[0124] Stage 1: Filling begins, using Class II medium displacement, Class II medium sand ratio or Class III high sand ratio construction to fill the lower weak deficit area.

[0125] Stage 2: Use Class III high displacement, Class II medium sand ratio or Class I low sand ratio for enhanced squeeze injection, and construct and fill most of the bottom of the upper strong deficit area.

[0126] Stage 3: Use Class III high displacement, Class II medium sand ratio or Class...

Embodiment 3

[0128] According to the discrimination of the heterogeneity mode of the sand production deficit profile, it is judged that it belongs to or is close to type C: the middle-weak edge-strong type composed of a weak deficit in the middle and strong deficits on the upper and lower sides, see figure 2 ; According to the class division of displacement and sand ratio described in embodiment 1, in conjunction with the characteristics of the above-mentioned C-type heterogeneous model, design the following staged pump injection construction procedures:

[0129] Stage 1: Filling begins, using Class II medium displacement and Class I low sand ratio construction.

[0130] Stage 2: Stop adding sand to stop sand injection, increase the displacement to the high displacement of Class III, and continue construction.

[0131] Stage 3: Reduce the displacement to level II medium displacement, increase the sand ratio to level II medium sand ratio or level III high sand ratio for sand filling and ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com