One-hole dual-purpose technology capable of meeting underground pressure relief and hydrogen sulfide treatment

A hydrogen sulfide and dual-purpose technology, applied in chemical instruments and methods, mining equipment, mining equipment, etc., can solve problems such as large consumption, physical hazards, personal safety and health hazards of underground operators, and achieve cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

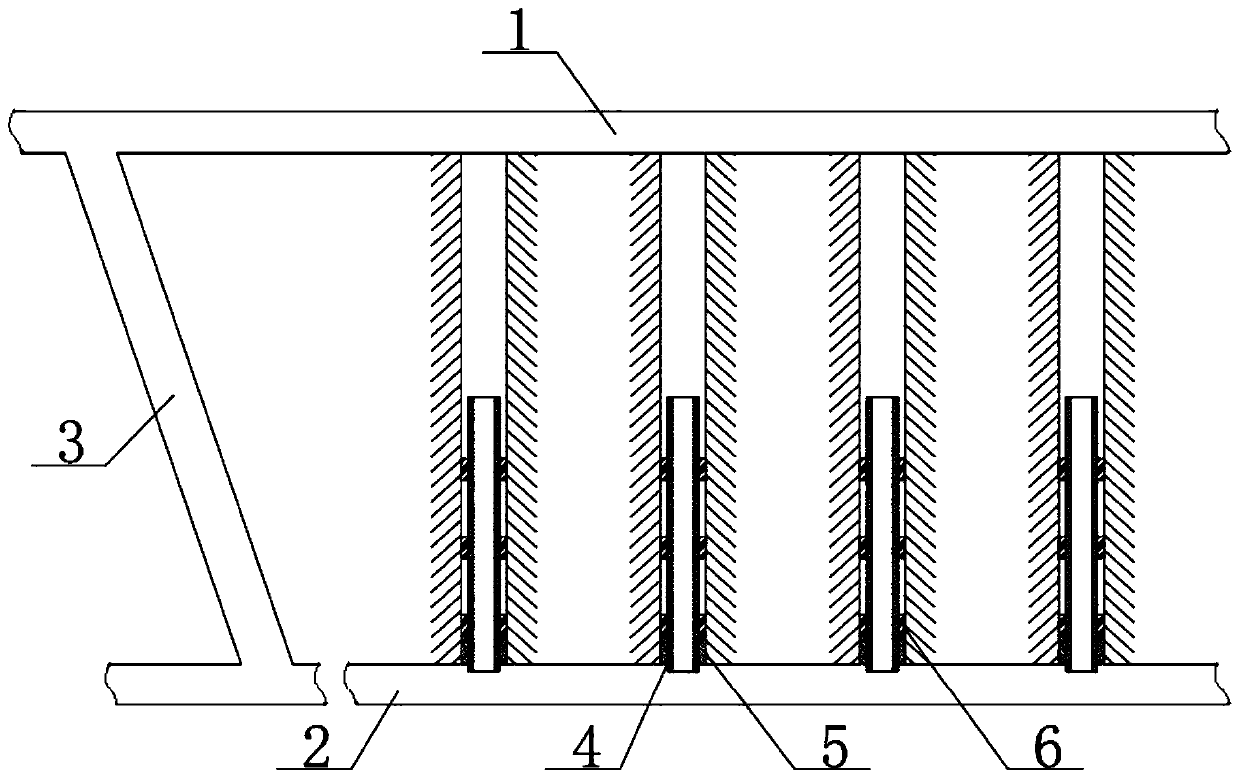

[0016] see figure 1 , the present invention provides a technical solution:

[0017] A one-hole dual-purpose technology that can satisfy downhole pressure relief and hydrogen sulfide treatment, including a transport channel 1, a return air channel 2 and a measure channel 3, and a return air channel 2 is provided below the transport channel 1, The transportation chute 1 and the return air chute 2 are connected through a measure trough 3, and a drill hole is opened between the transportation chute 1 and the return air chute 2, and a PVC pipe 4 is arranged inside the borehole , the top of the air return trough 2 is connected with a PVC pipe 4 , and the outer side of the PVC pipe 4 is covered with a first wrapping layer 5 and a second wrapping layer 6 .

[0018] The first wrapping layer 5 is made of cement material, and the bottom end of the first wrapping layer 5 fits with the air return slot 2, and the width of the first wrapping layer 5 is 500 mm; The second wrapping layer 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com