A welding method for friction stir welding of dissimilar materials

A friction stir and welding method technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of high replacement cost, high mixing head cost, mixing head wear, etc., and achieve overall cost reduction and welding quality. The effect of reducing and improving time efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A stirring head for friction stir welding of dissimilar materials, comprising a shoulder 1 and a stirring pin 2 arranged at the center of the bottom of the shoulder 1 and protruding downward. The material of the shoulder 1 is H13 steel, and the material of the stirring pin 2 is Tungsten-rhenium alloy.

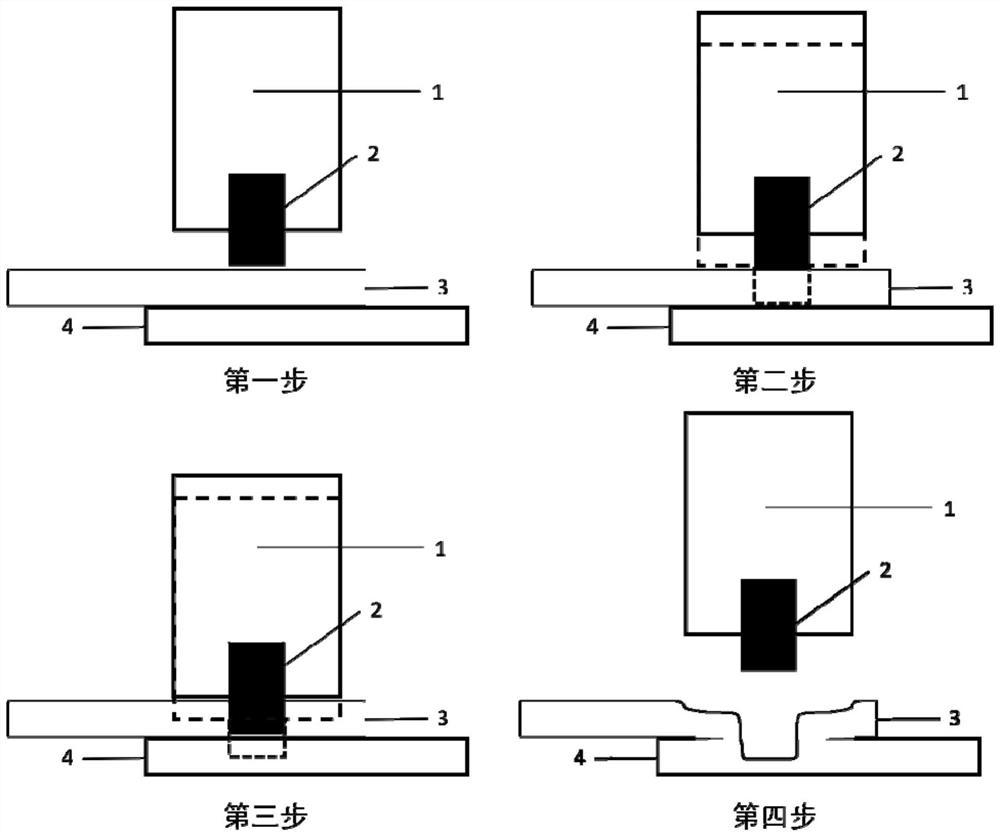

[0019] The above stirring head is used for the welding of two dissimilar materials, wherein the upper layer metal 3 is AM60B magnesium alloy material, and the lower layer metal 4 is DC01 low carbon steel material, the specific steps are as follows figure 1 Shown:

[0020] In the first step, the softer AM60B magnesium alloy material is placed on the upper side, and the harder DC01 low-carbon steel material is placed on the bottom;

[0021] The second step: rotate the stirring head, use a higher pressing speed to make the stirring needle 2 part of the composite stirring head move inside the softer material, wherein the rotating speed of the stirring head is selected as 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com