Multichannel heat exchanger flow distribution prediction method

A flow distribution and prediction method technology, applied in the field of heat exchanger design, can solve problems such as deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

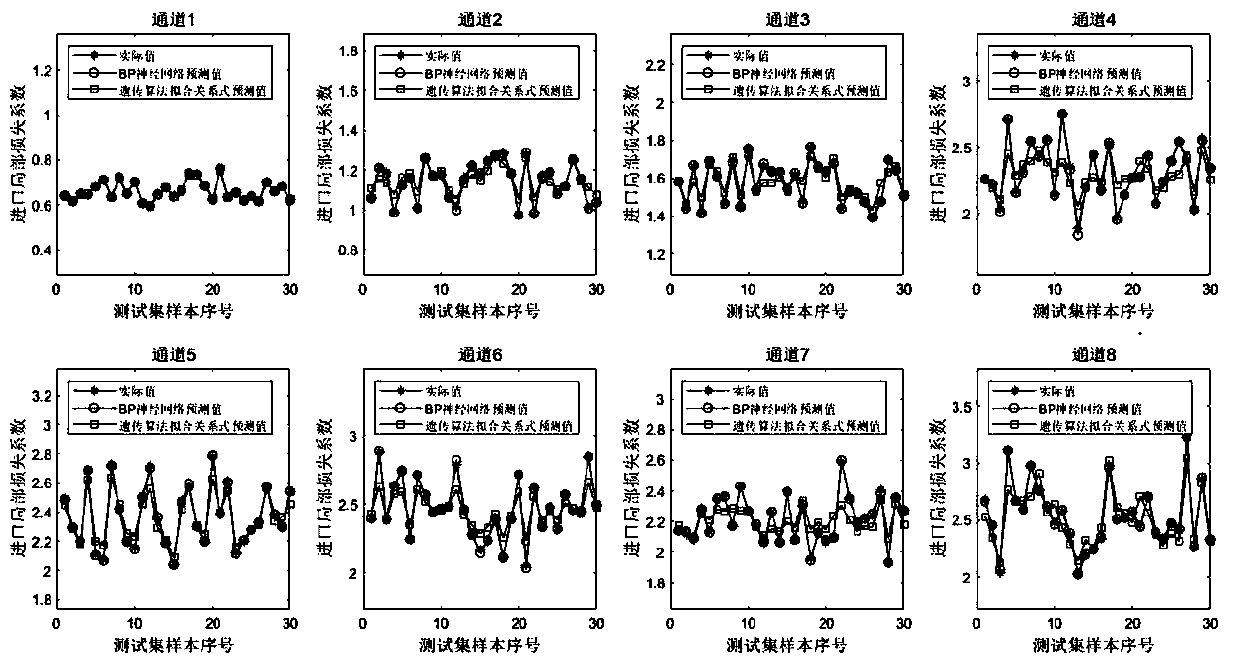

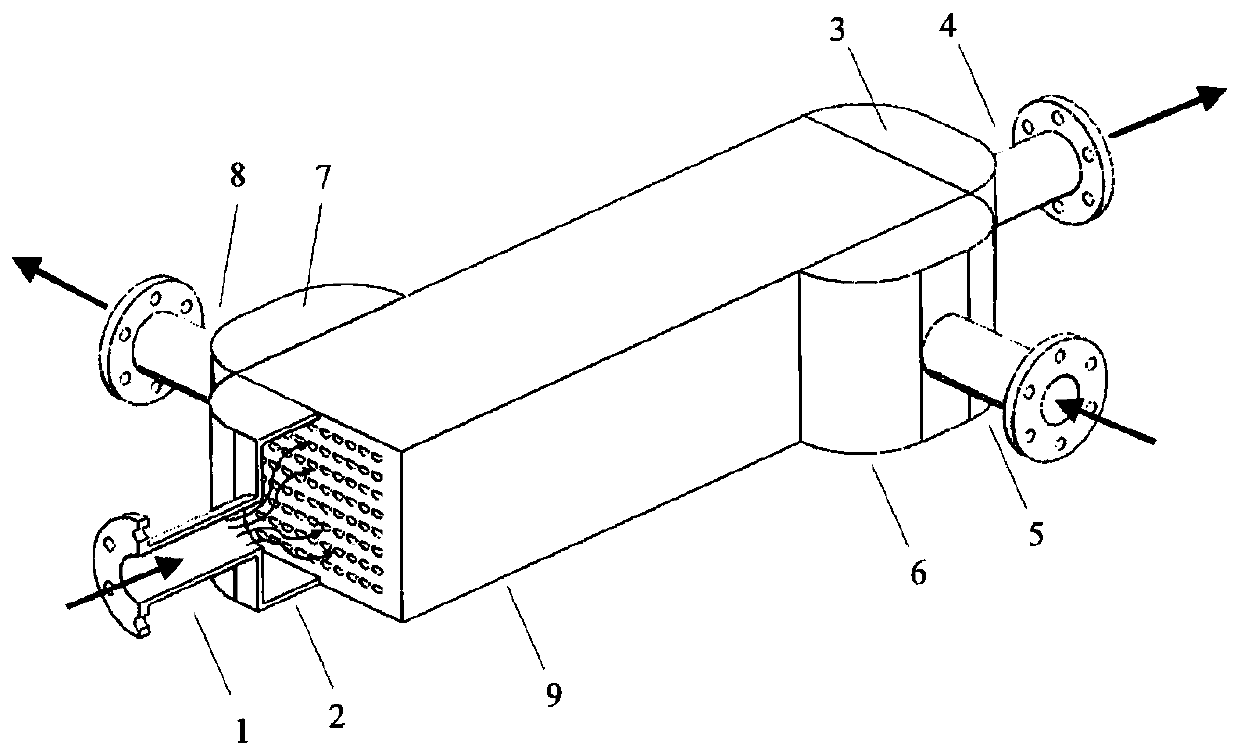

[0047] Provide the embodiment of the present invention below, Figure 4 In the multi-channel heat exchanger shown, the fluid on one side flows through the inlet pipe successively and enters the inlet head cavity, and then splits to each heat exchange channel, exchanges heat in the heat exchange core, and then converges to the outlet head cavity , and finally enters the outlet pipe and flows out of the heat exchanger. Its heat exchange channels are arranged in 8×4. Considering the symmetry, in the CFD calculation, it can be simplified by taking a quarter of it and then taking the symmetrical boundary treatment. Follow the steps below to Figure 4 The flow distribution of the multi-pass heat exchanger shown is predicted by:

[0048] 1) Determine if Figure 4 The shown multi-channel heat exchanger core channel and inlet and outlet structure, determine the geometric parameters;

[0049] 2) Use Solidworks to establish such as Figure 5 The geometric model of the inlet part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com