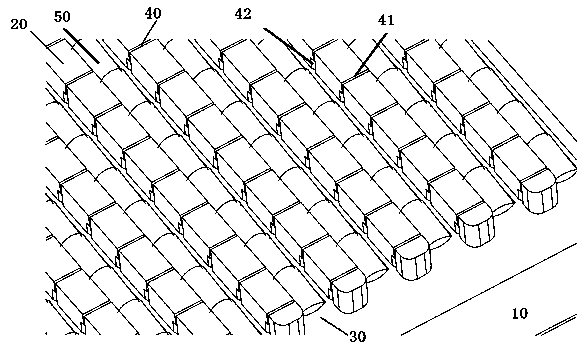

Bipolar plate for squamous flow-diversion fuel cell containing capillary groove ridges

A fuel cell and bipolar plate technology, applied in the direction of fuel cells, fuel cell components, circuits, etc., can solve the problems of low water carrying capacity and water discharge efficiency of fuel cells, affecting the overall performance of fuel cells, etc., to achieve improved moisture Effects of discharge efficiency, improvement of gas mass transfer performance, and improvement of water-carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for preparing a bipolar plate for a fuel cell according to the present invention is provided, comprising the steps of:

[0038] Step 1. Use a graphite plate with a thickness of 1.5mm as the substrate;

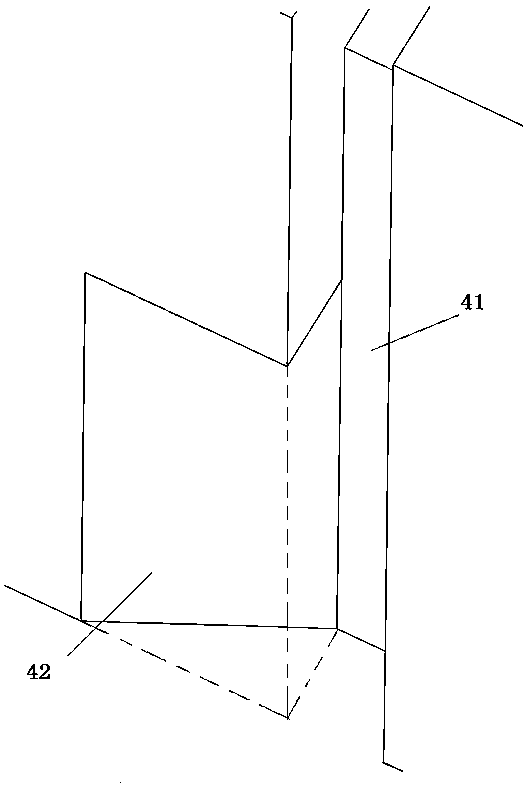

[0039] Step 2. The flow field of the bipolar plate adopts parallel flow channel design, the width of the ridge of the flow channel is 0.6mm, the width of the flow channel groove is 0.8mm, and the depth of the flow channel groove is 0.6mm;

[0040] Step 3, the capillary groove design is as follows: ①The upper rectangular groove of the capillary groove is on the three surfaces of the runner ridge, the groove width is 0.05mm, the groove depth is 0.1mm, and the first rectangular groove is 0.4mm away from the top of the runner ridge;② The right-angled triangular groove at the lower part of the capillary groove ridge is on the two sides of the runner ridge, the lengths of the two right-angled sides of the right-angled triangle are 0.1mm and 0.05mm respectively, and th...

Embodiment 2

[0044] Step 1, using a graphite plate with a thickness of 1.5mm as the base material;

[0045] Step 2. The flow field of the bipolar plate adopts parallel flow channel design, the width of the ridge of the flow channel is 0.6mm, the width of the flow channel groove is 0.8mm, and the depth of the flow channel groove is 0.6mm;

[0046] Step 3. The design of the capillary ridge is as follows: ①The upper rectangular groove of the capillary ridge is on the three surfaces of the runner ridge, the groove width is 0.06mm, the groove depth is 0.15mm, and the first rectangular groove is 0.5mm away from the top of the runner ridge; ② The right-angled triangular grooves at the lower part of the capillary ridges are on the two sides of the runner ridges, the lengths of the two right-angled sides of the right-angled triangles are 0.15mm and 0.06mm respectively, and the groove depth is 0.2mm;

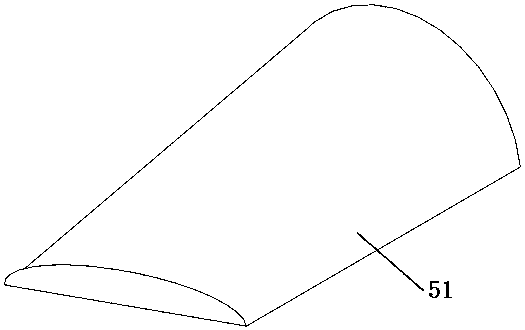

[0047] Step 4, the design of the squamous ridge is as follows: ①The length of the squamous ridge i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com