Ethyl acetate energy-saving production system and corresponding energy-saving production process

A technology of ethyl acetate and production process, which is applied in the field of organic compound preparation, can solve the problems that the moisture index of finished ethyl acetate cannot be directly achieved, the production capacity of the esterification tower is reduced, and the ability of reflux to carry water is poor, so as to achieve simple structure and reduce reflux Ratio, the effect of reducing the gas-liquid phase load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

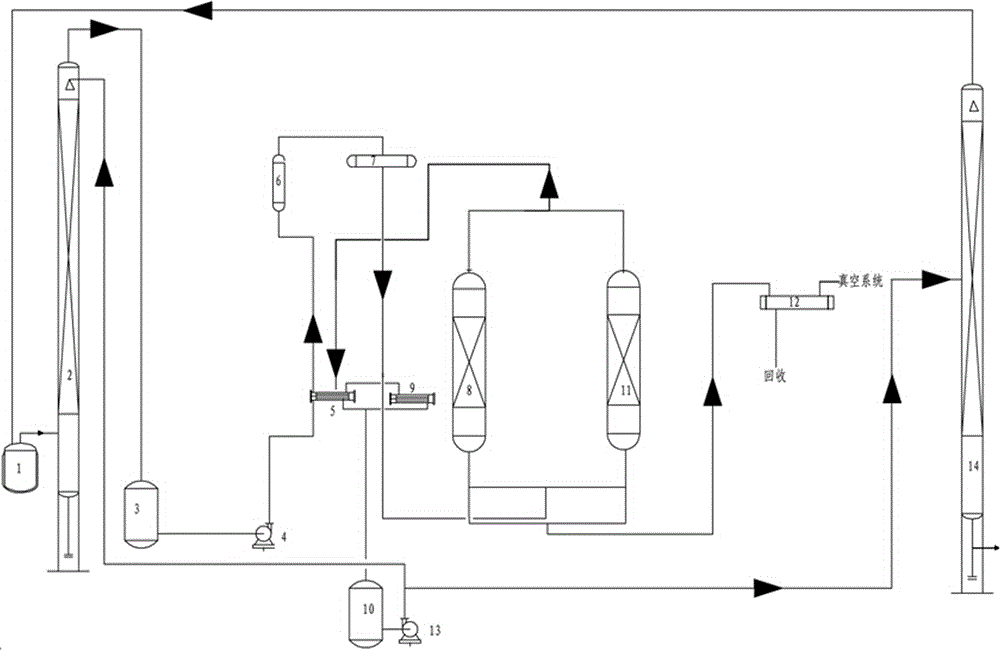

[0035] Example 1 A kind of energy-saving production system of ethyl acetate

[0036] The energy-saving production system of ethyl acetate of the present embodiment is as figure 1 As shown, it includes an esterification tank 1 for carrying out the esterification reaction, and an esterification tower 2 connected to the esterification tank 1 through a pipeline.

[0037] The esterification kettle 1 is provided with a discharge inlet and a feed inlet. The esterification tower 2 is provided with a feed inlet, a return inlet and a steam outlet.

[0038] The vapor outlet of the esterification tower 2 is connected to the esterification buffer tank 3 and the molecular sieve tower feed pump 4 through pipelines in sequence.

[0039] This embodiment also includes a molecular sieve dehydration device composed of a preheater 5 , an evaporator 6 , a superheater 7 , a first molecular sieve bed 8 , a condenser 9 and a regeneration condenser 12 .

[0040] The molecular sieve feed pump 4 ...

Embodiment 2

[0054] Example 2 A kind of energy-saving production process of ethyl acetate

[0055] The energy-saving production process of ethyl acetate provided in this example includes esterification process, molecular sieve dehydration process, light removal process, refining process and recovery process carried out in sequence. This technology relies on the energy-saving production system of the ethyl acetate provided in the embodiment 1 to realize, and technological process is as follows:

[0056] After the raw materials are heated and catalyzed in the esterification kettle 1, ethyl acetate and water are generated. Ethyl acetate, water and unreacted ethanol can form ethyl acetate-water-ethanol ternary azeotrope or ethyl acetate-water, Water-ethanol, ethyl acetate-ethanol binary azeotrope, the mixture A extracted from the top of the tower is sent to the esterification tower 2 for rectification and separation; in order to improve the moisture content of the gas phase extracted from...

Embodiment 3-7

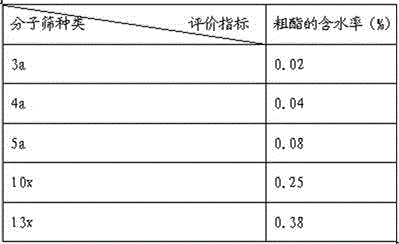

[0060] Example 3-7 Energy-saving Production Process of Ethyl Acetate

[0061] Embodiment 3-7 is respectively a kind of energy-saving production technology of ethyl acetate, and the technological parameter of technological process and relevant operation is identical with embodiment 2, and the type of molecular sieve is 3a, and difference is only in esterification tower pressure and molecular sieve The corresponding control parameters in the dehydration section are different, see Table 1 for details.

[0062]

[0063] In Example 3-7, after the crude esters generated are dehydrated in the molecular sieve section, the water content of the crude esters is ≤0.05%, and the ethanol content of the organic phase extracted from the top of the light removal tower is about 25%, and the corresponding ethyl acetate they provide The energy-saving production process of esters has the characteristics of simple process flow and easy control. The dehydrated ethyl acetate directly reaches ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com