Fully automatic ridge cropping strawberry picking robot and use method thereof

A picking robot and fully automatic technology, applied in picking machines, applications, manipulators, etc., can solve the problems of low work efficiency and high labor intensity of operators, and achieve the effect of high work efficiency and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

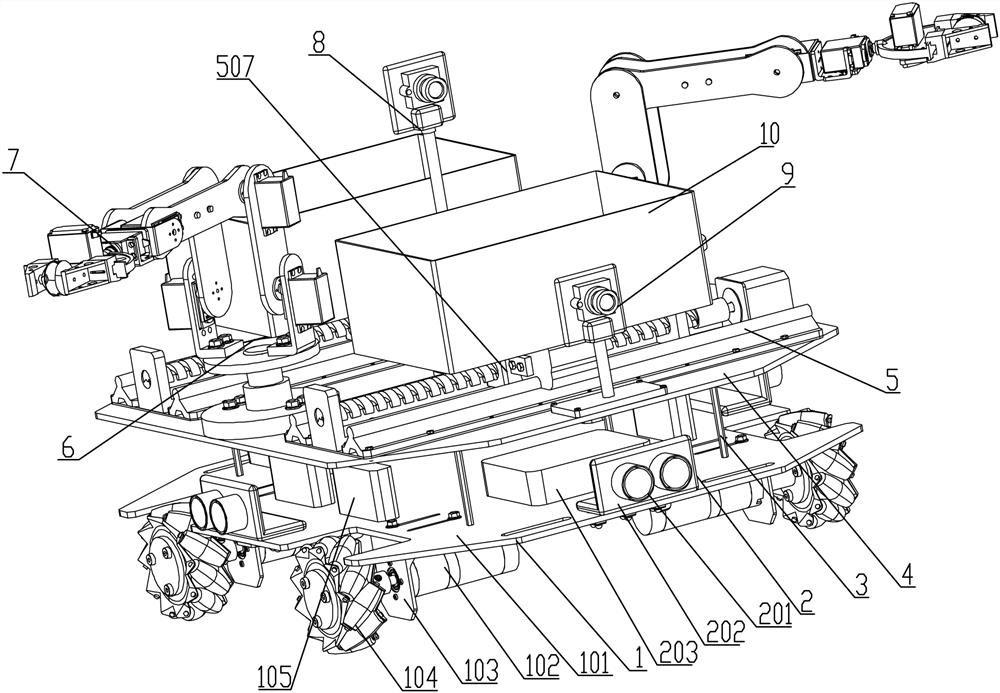

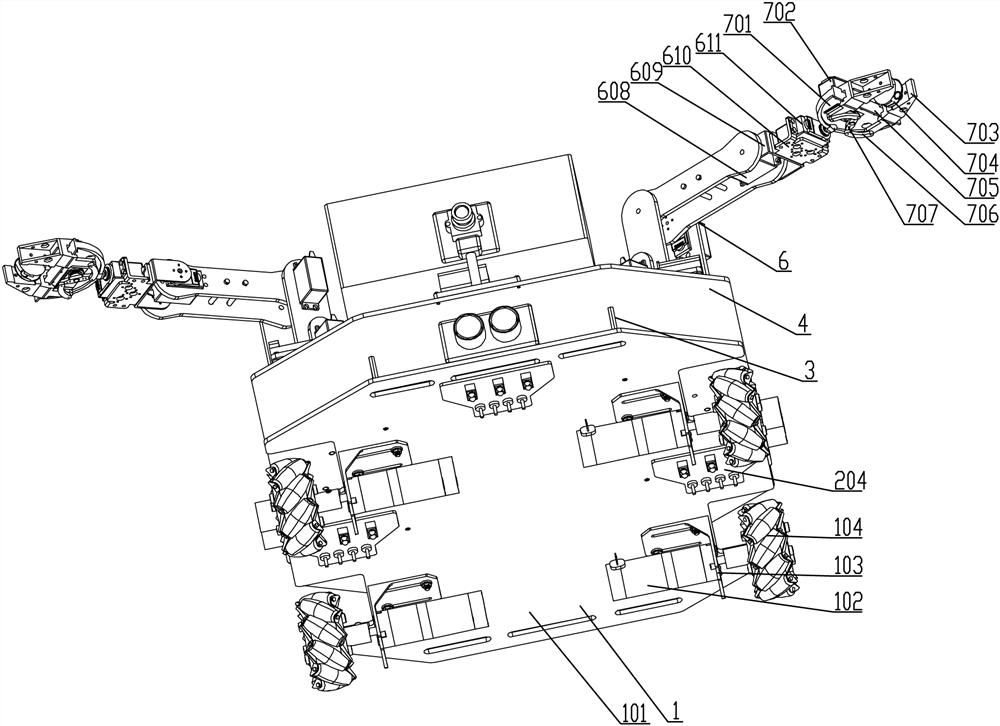

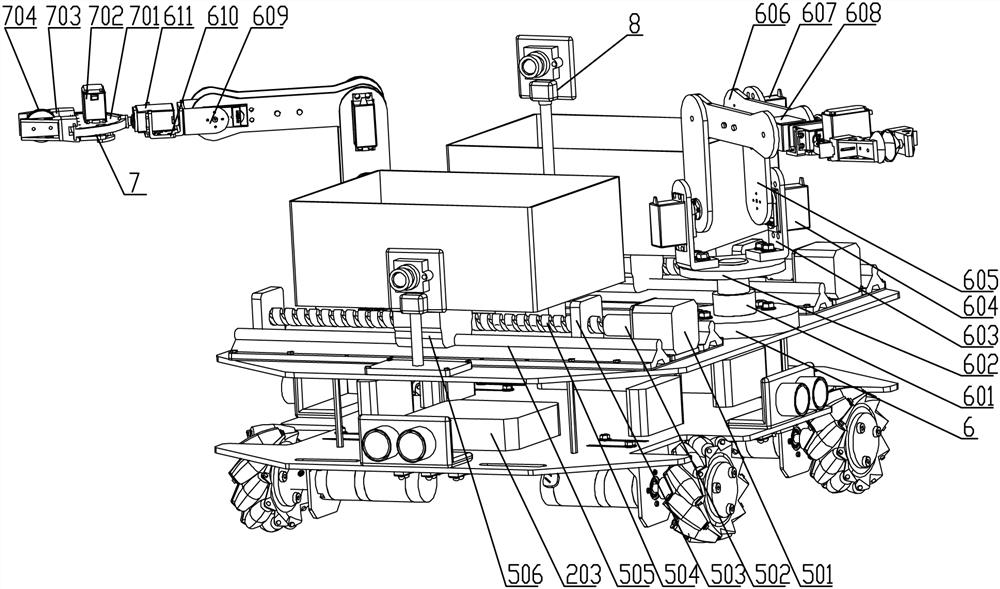

[0043] see Figure 1-4, a fully automatic ridge-type strawberry picking robot, which includes a mobile chassis device 1 for driving the entire robot to walk; the mobile chassis device 1 is equipped with an automatic tracking device 2 for controlling the moving path of the robot; the mobile chassis device 1 The top of the top is supported with a top plate 4 by a plurality of supporting columns 3, and a multi-degree-of-freedom mechanical arm 6 is installed symmetrically on both sides of the top of the top plate 4, and the end of the multi-degree-of-freedom mechanical arm 6 is equipped with a manipulator for picking strawberries. 7; The two sides of the multi-degree-of-freedom mechanical arm 6 are arranged symmetrically on the top of the top plate 4, and a screw mechanism 5 is installed, and a strawberry storage frame 10 for holding strawberries is installed on the screw mechanism 5, and the top plate 4 is installed with the fruit identification detection device that is used to i...

Embodiment 2

[0052] The method for using the fully automatic ridge farming strawberry picking robot comprises the following steps:

[0053] Step 1: put the above-mentioned robot into the position between the planting ridges of the strawberry plantation;

[0054] Step 2: Start the above-mentioned robot, and control the robot to walk inside the plantation through the mobile chassis device 1 and the automatic tracking device 2, and walk along the strawberry planting ridge;

[0055] Step 3: In the process of walking, start the above-mentioned fruit identification and detection device, identify the stems, leaves, flowers, and fruit colors of the strawberry crop through the first camera 9 and the second camera 801 of the fruit identification and detection device, and according to the preset strawberry Shape contour threshold and color threshold to realize strawberry recognition;

[0056] Step 4: After the strawberry identification is completed, the controller 203 controls the action of the mult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com