High-speed dispersion machine for chemical engineering

A high-speed dispersing machine, chemical technology, applied to mixers with rotating stirring devices, mixers, mixer accessories, etc., can solve the problems of inconvenient removal of paint, unfavorable paint dispersion, etc., and achieve the effect of accelerating fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

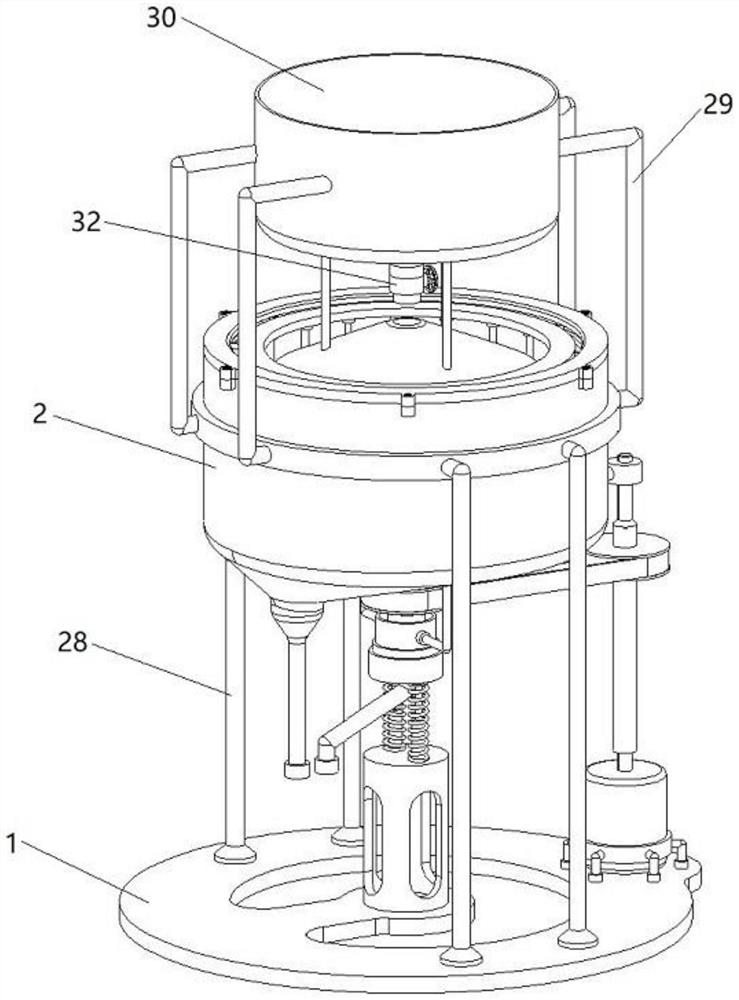

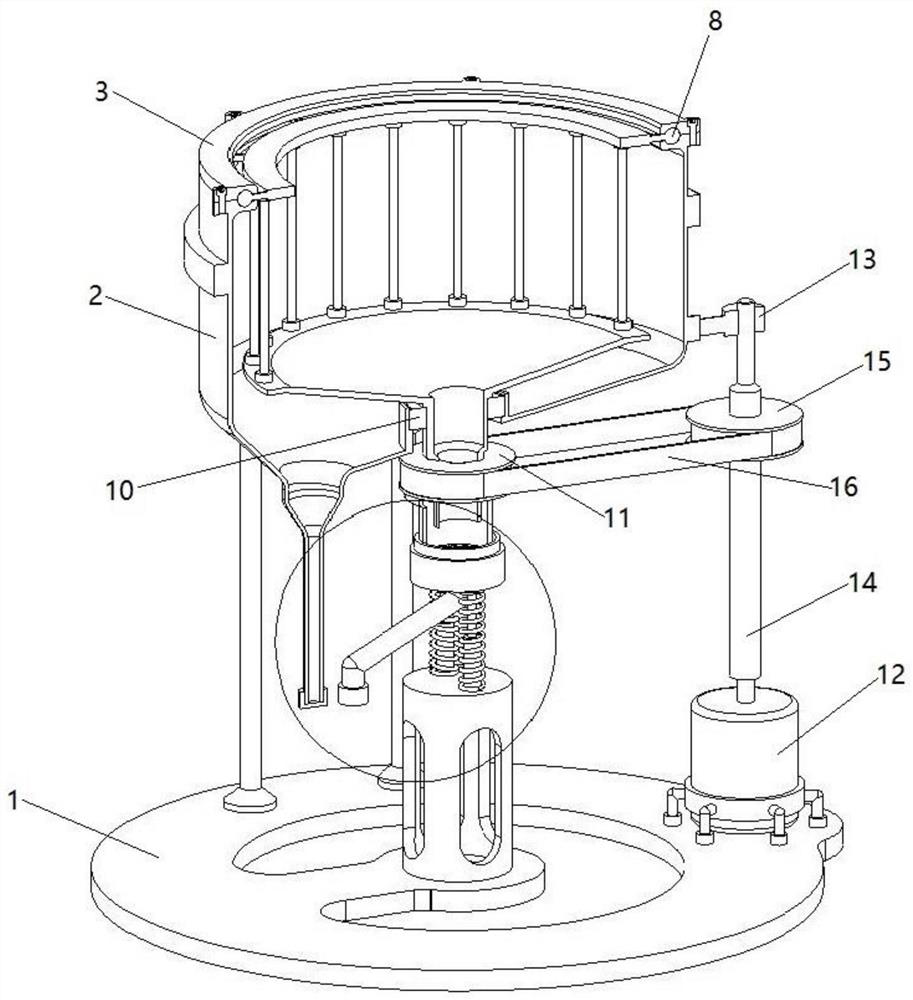

[0030] A high-speed dispersing machine for chemical industry, such as Figure 1-Figure 4 As shown, it includes a support frame 1, a funnel-shaped cylinder 2, a dispersion mixing assembly, a power assembly and a feeding assembly. The dispersing and mixing assembly for dispersing and mixing materials in a rotating manner, the power assembly powered by a motor for rotation is provided on the rear side of the support frame 1, and the unloading assembly is provided below the dispersing and mixing assembly for unloading through a pipeline.

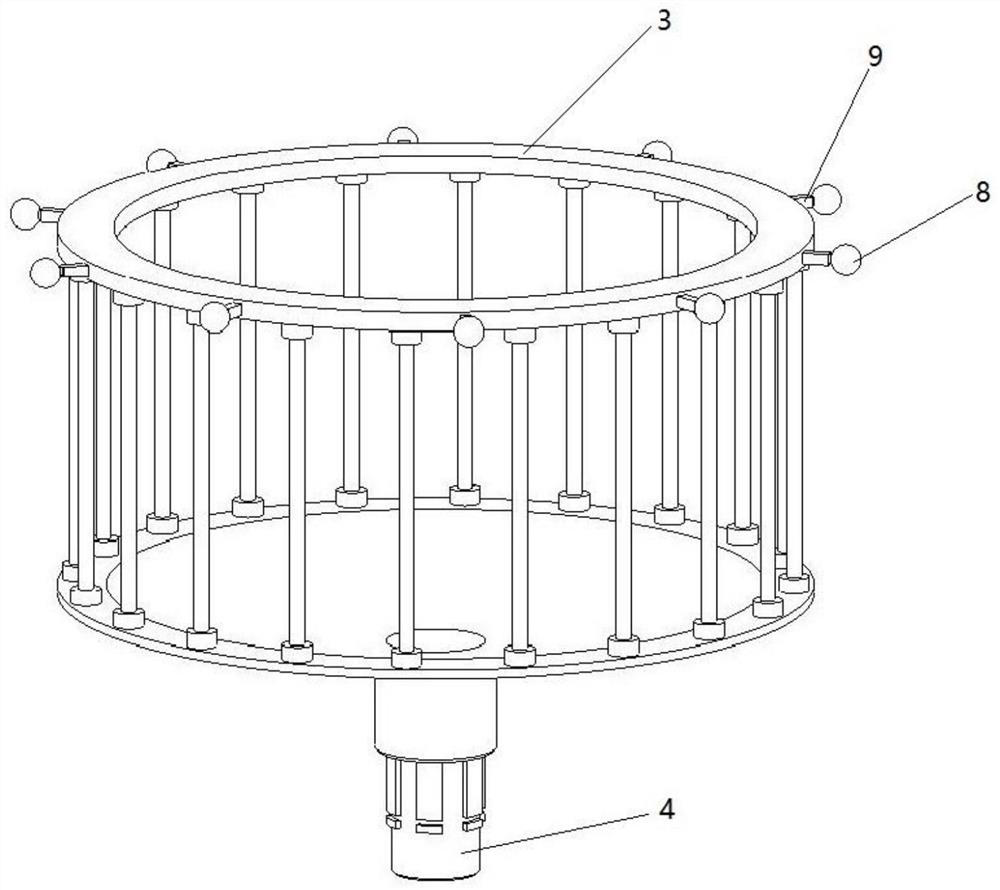

[0031] Such as figure 2 , image 3 , Figure 6 , Figure 7 and Figure 12 As shown, the dispersion mixing assembly includes an annular frame 3, a liquid outlet pipe 4, a sliding ball fixing ring 6, a sliding ball 8, a connecting rod 9, and a bearing 10. The top of the funnel-shaped cylinder 2 is provided with a first semicircular sliding groove 5, and the funnel A sliding ball fixing ring 6 is installed on the top of the type cylinder 2, a...

Embodiment 2

[0039] On the basis of Example 1, such as image 3 , Figure 4 , Figure 8 , Figure 9 , Figure 10 , Figure 11 and Figure 12 As shown, it also includes a liquid outlet support 19, a filter frame 20, a support column 21, a lifting pipe 22, a liquid outlet frame 23, a second cover 24, a liquid outlet inclined pipe 25, a lifting rod 26, a spring 27, and a funnel The bottom of the type cylinder 2 is suspended and welded with a liquid outlet bracket 19, a filter frame 20 is installed below the liquid outlet bracket 19, a liquid outlet frame 23 is installed below the filter frame 20, and a lifting rod 26 and a lifting rod 26 are welded below the liquid outlet frame 23. Liquid outlet inclined pipe 25, the end of liquid outlet inclined pipe 25 is equipped with a second cover 24, support column 21 is equipped with on the support frame 1, is welded with lifting pipeline 22 on the support column 21, between lifting pipeline 22 and lifting rod 26 Spring 27 is housed between.

[00...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap