T-shaped track cleaning device for precision electromechanical equipment

A precision electromechanical and cleaning device technology, applied in the field of track cleaning, can solve the problems of waste of resources, waste of cleaning fluid, inconvenience for users, etc., and achieve the effects of reducing consumption, improving utilization rate, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

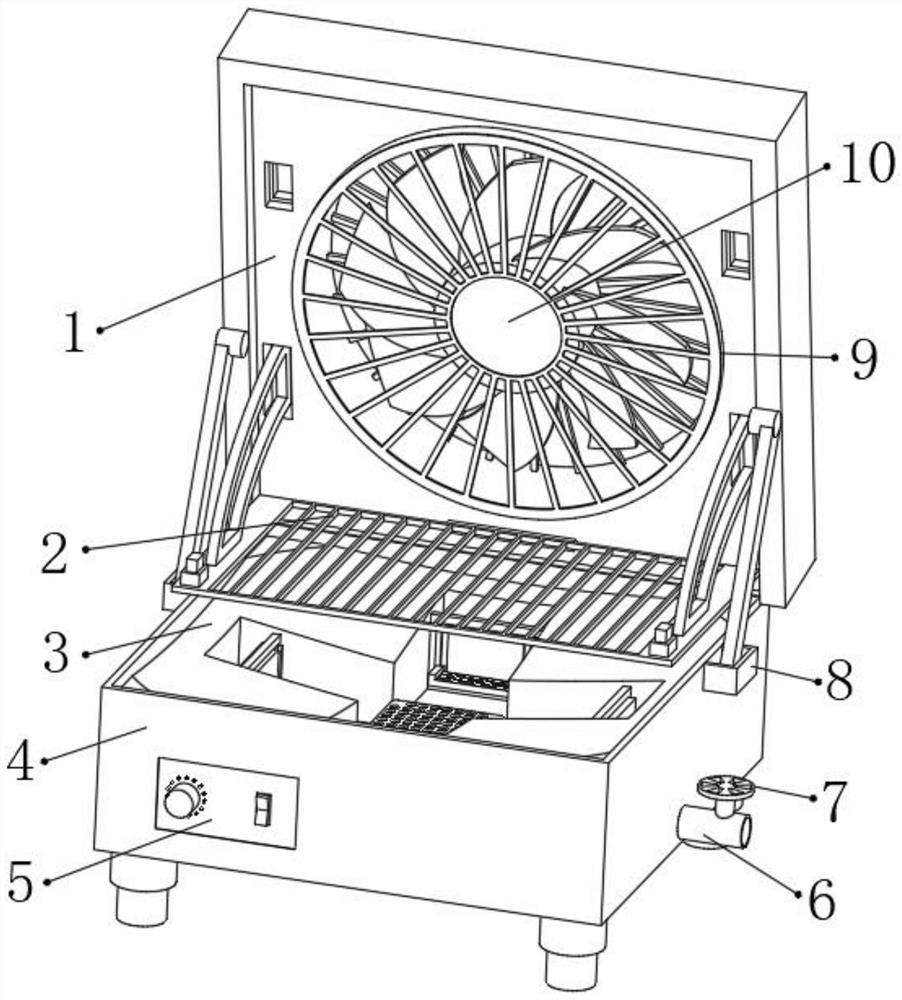

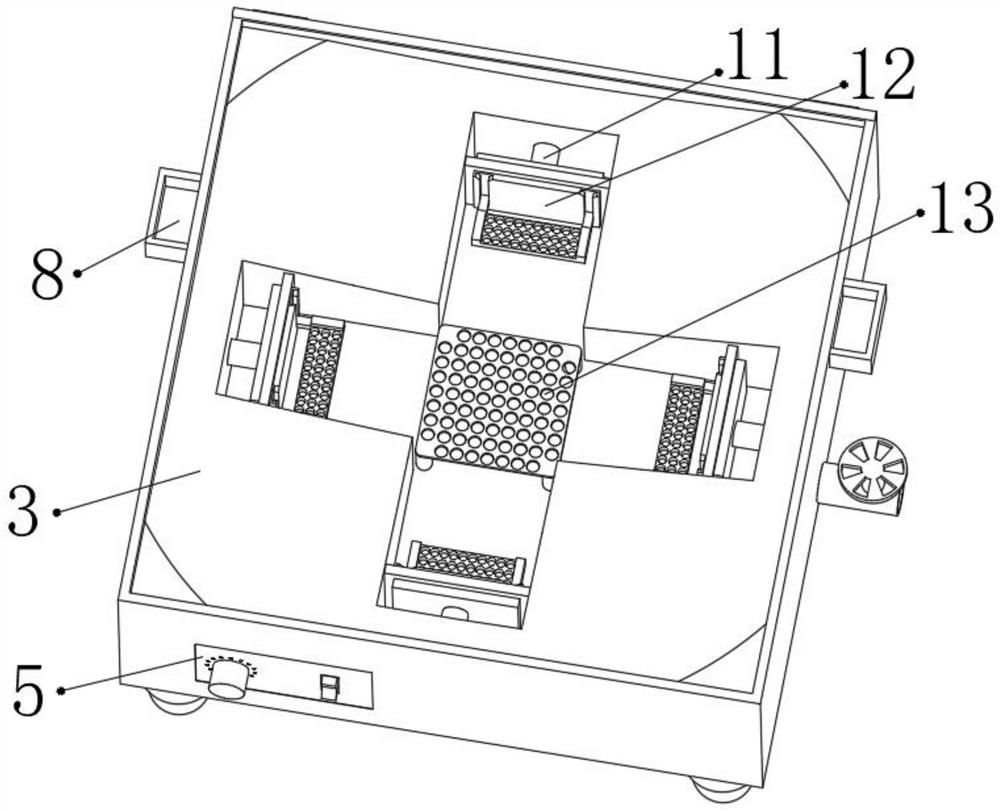

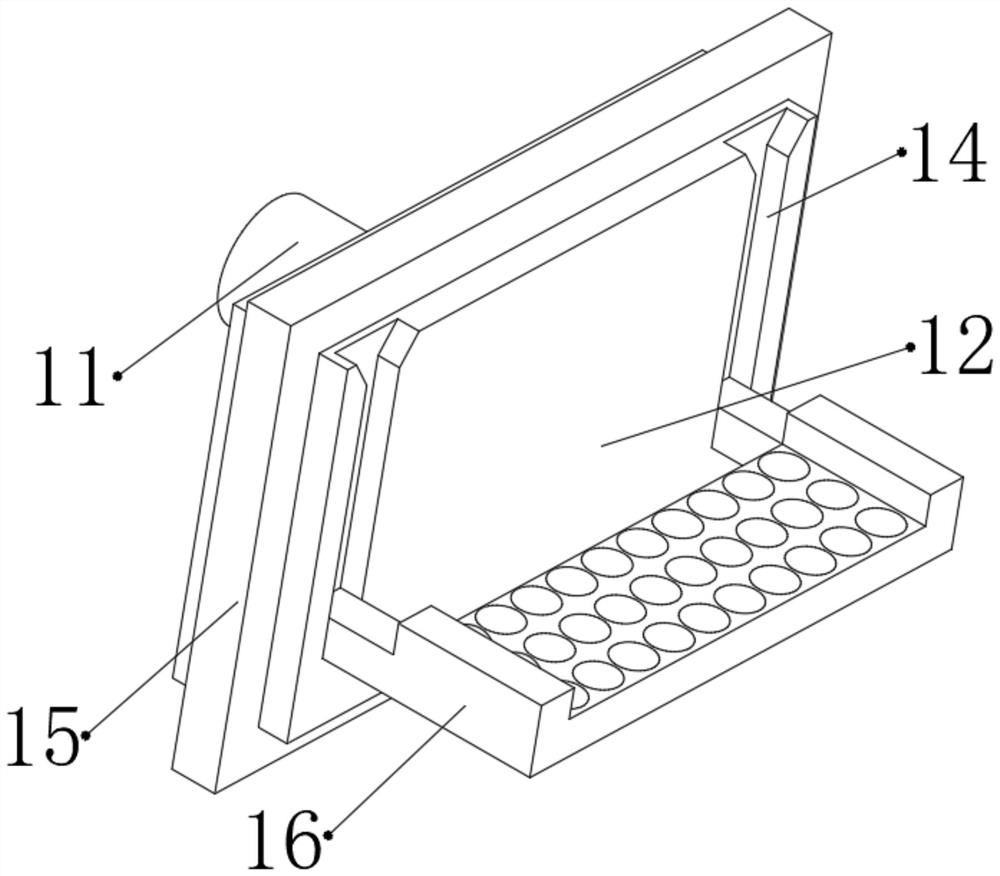

[0033] refer to Figure 1-6 , a T-shaped track cleaning device for precision electromechanical equipment, including a housing 4, the inner wall of the housing 4 near the top is connected with a cleaning table 3 by screws, and the top outer wall of the cleaning table 3 is provided with a "ten"-shaped cleaning tank for cleaning The top outer wall of the table 3 is set as an inwardly inclined slope. The inside of the cleaning table 3 is located at the four ends of the "ten" shape and is connected with an electric telescopic rod 11 by screws, and one end of the electric telescopic rod 11 is connected with an adjustment plate 12 by a screw. And the outer wall of the adjusting plate 12 is connected with a sealing gasket 15 by screws, and the periphery of the sealing gasket 15 is compatible with the cleaning tank, and the outer wall of one side of the adjusting plate 12 has a Y-shaped limiting groove 14, and the limiting groove 14 The inner wall is slidably connected with a second pl...

Embodiment 2

[0037] refer to Figure 7 , a T-shaped track cleaning device for precision electromechanical equipment. Compared with Embodiment 1, this embodiment has a barrier plate 24 placed on the outer wall of the top of the cleaning table 3, and the outer wall of the barrier plate 24 has a water leakage hole 23. The barrier plate 24 The top outer wall is fixed with a handle 25.

[0038] Working principle: when in use, turn over the cover 1 and insert one end of the fixing rod 21 on the cover 1 into the fixing hole on the fixing block 8, the fixing rod 21 supports the cover 1 to fix the position of the cover 1, When cleaning, place the first placing plate 13 in the center of the "ten" of the cleaning tank, and snap the second placing plate 16 into the limit groove 14, and then adjust the electric telescopic rod 11 to expand and contract according to the size of the T-shaped track, so as to move Adjust the position of the plate 12 to adjust the size of the cleaning tank, so that the amou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com