Graphene/silicon dioxide ionic liquid layered liquid crystal lubricant and preparation method thereof

A silicon dioxide and ionic liquid technology, applied in the field of lubrication, can solve problems such as restricted application and poor dispersion, and achieve the effect of simple method and good lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

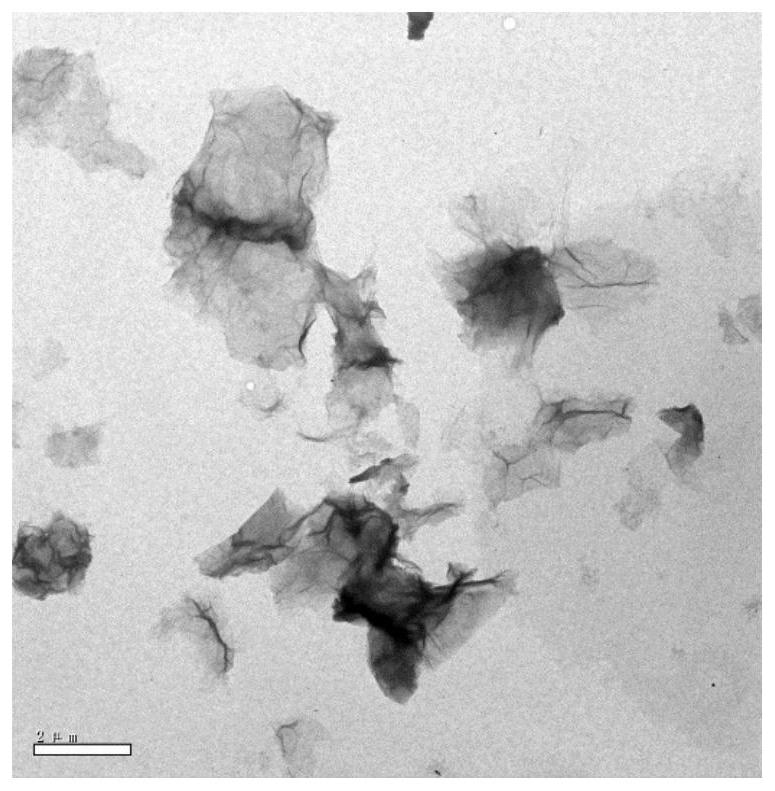

[0034] (1) prepare graphene dispersion liquid (H 2 o Graphene ): Weigh 0.2 g of Triton X-100 in a 100mL beaker to obtain an aqueous solution of 0.2 wt% Triton X-100, and then add graphene to the solution to prepare 0.1, 0.2, 0.3, 0.4, 0.5 mg / mL of the mixture, ultrasonicated in an ultrasonic cleaner for 24 hours, and finally a uniform black dispersion was obtained.

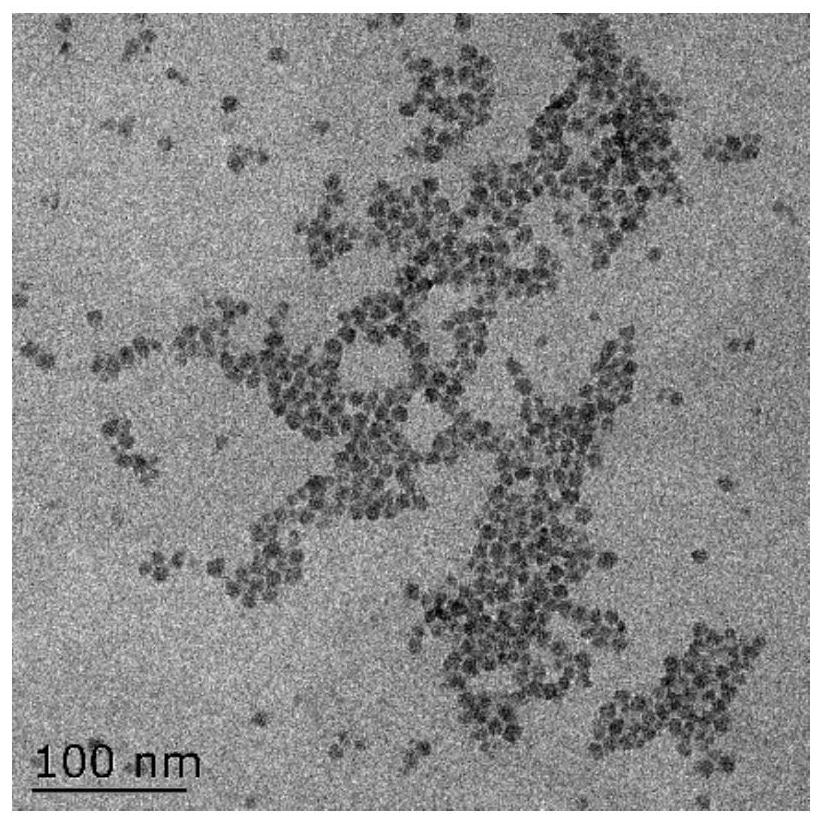

[0035] (2) prepare silicon dioxide dispersion liquid (H 2 o SiO2 ): Dissolve silica sols with particle sizes of 4.2 nm, 11.5 nm, and 25.6 nm in water and dilute them into a series of dispersions with mass concentrations of 0, 0.5, 1.0, 1.5, 2.0, and 2.5 wt%.

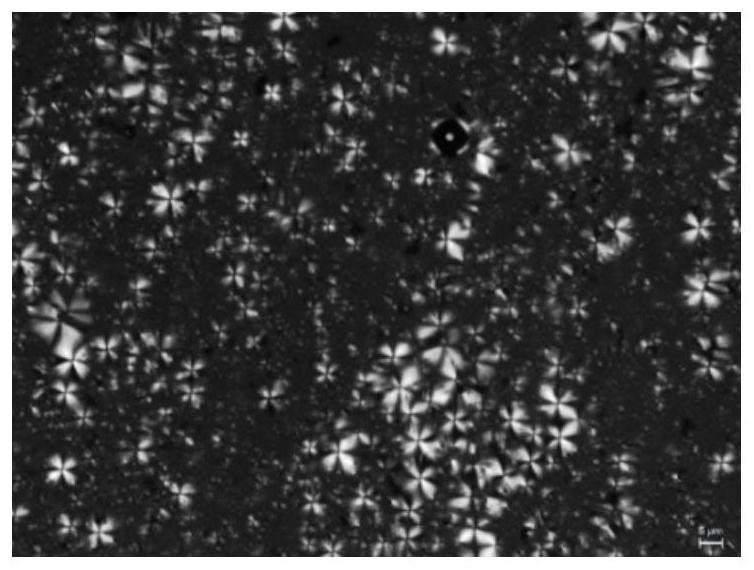

[0036] (3) Preparation of graphene / silica ionic liquid layered liquid crystal: fixed component Triton X-100:C 16 mimNTf 2 : H 2 o Graphene : H 2 o SiO2 = 54.6: 16.5: 14.3: 14.3. Add surfactant Triton X-100 and ionic liquid C 16 mimNTf 2 , first fix the mass fraction of silica to 1.0 wt%, add different concentrations of graphene dispersions to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com