Shaft bottom stress-induced unloading drill bit and method for increasing drilling speed

A stress unloading and drill bit technology, which is applied in the direction of drill bits, drilling equipment, drill pipes, etc., can solve the problems of rock breaking energy attenuation at the bottom of the well, complex tool structure, and low drilling efficiency. Facilitate the effect of promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

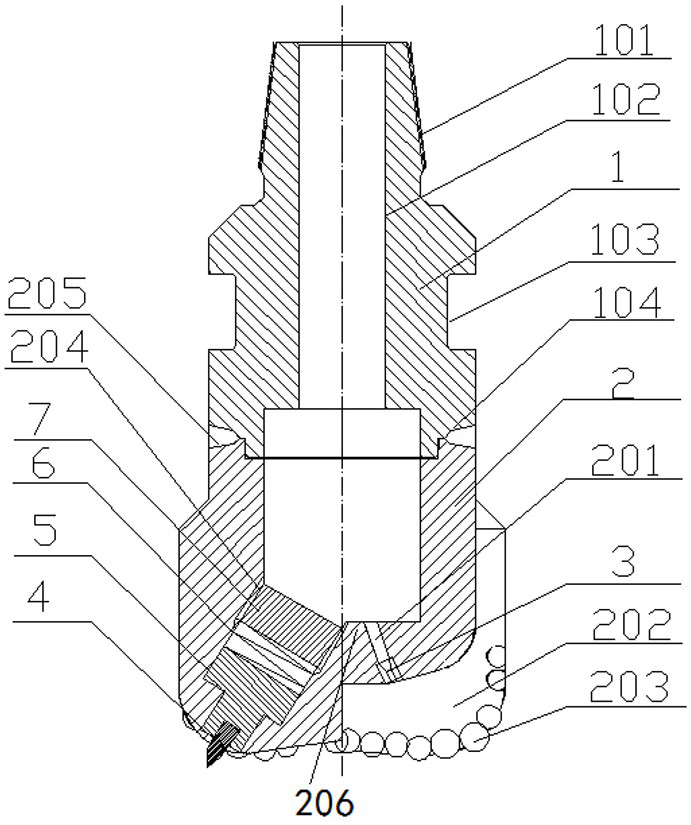

[0032] Embodiment 1, with reference to attached figure 1 , a bottom hole stress-induced unloading drill bit mentioned in the present invention includes a drill bit body 2, a support block 7, a spring 6, a stress unloading tooth matrix 5 and a stress unloading tooth 4, the support block 7, the spring 6, The stress unloading tooth parent body 5 is all installed in the special installation hole 204 of the shoulder of the drill bit body 2, and the stress unloading tooth 4 is installed on the stress unloading tooth parent body 5 and is located outside the drill bit body 2; the spring 6 is installed on the side of the stress unloading tooth body 5 close to the inside of the drill body, and is located between the support block 7 and the stress unloading tooth body 5; the combination of the stress unloading tooth body 5 and the stress unloading tooth 4 can be relatively Sliding in the direction of the spring axis; the special mounting hole 204 is located at the shoulder of the drill b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com