Pulse solenoid valve

A solenoid valve, pulse type technology, applied in the direction of valve lift, valve details, valve device, etc., can solve the problem of continuous power supply of the valve, and achieve the effect of good heat dissipation, simple and compact structure, and easy manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

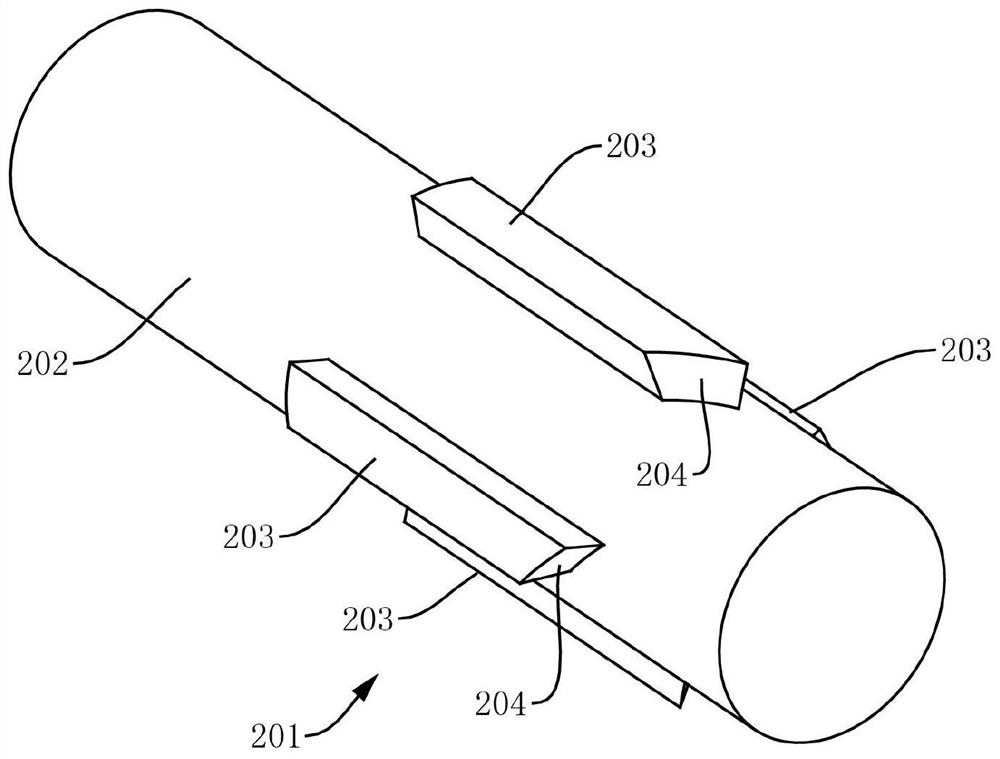

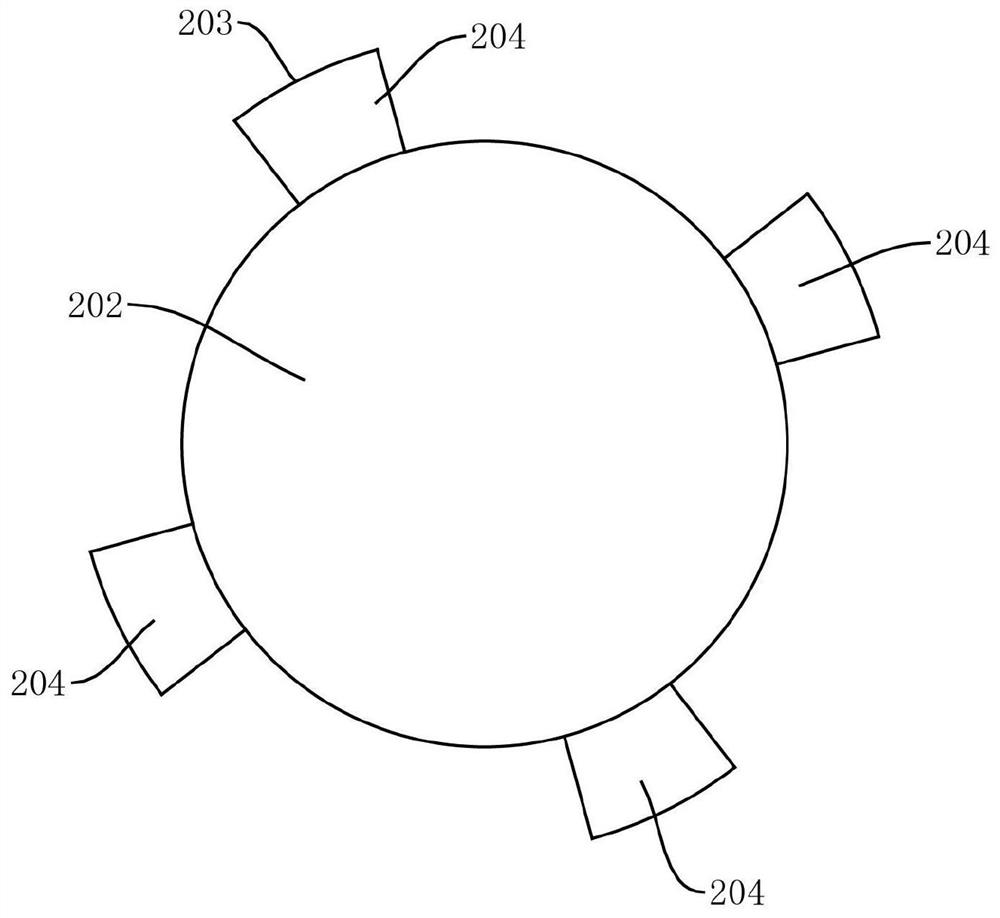

[0055] see Figure 1-Figure 10 In this embodiment, a pulse solenoid valve is provided, including a valve body 300, an electromagnetic mechanism, and an angle control mechanism 200. The valve body 300 is provided with an inlet 301 and an outlet 302, and the inlet 301 and the outlet 302 are arranged on the valve The internal channel 303 in the body 300 is connected, and the internal channel 303 is provided with a valve core 304, the valve core 304 is connected with the angle control mechanism 200 through the valve stem 305, and the electromagnetic mechanism is connected with the angle The control mechanism 200 is connected, wherein,

[0056] The electromagnetic mechanism is used to generate a magnetic force when receiving a pulse electric signal, and drive the angle control mechanism 200 to act through the magnetic force (one pulse electric signal acts once),

[0057] The angle control mechanism 200 is used to drive the valve stem 305 to rotate at a set angle under the drive of...

Embodiment 2

[0083] The main difference between this embodiment 2 and the above-mentioned embodiment 1 is that, in the pulse solenoid valve provided by this embodiment, a transmission mechanism is also provided between the valve stem 305 and the angle control mechanism 200, and the transmission mechanism One end of one end is connected with the valve rod 305, and the sliding sleeve 215 is arranged at the other end of the transmission mechanism, and the transmission ratio of the transmission mechanism can be greater than 1 or equal to 1.

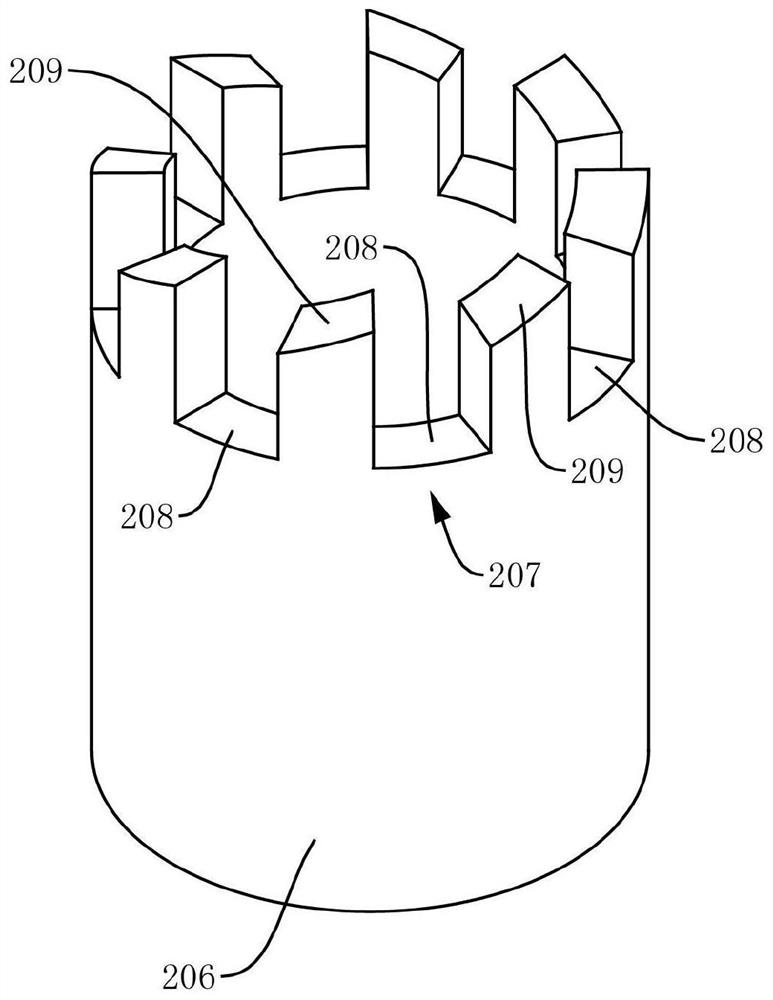

[0084] In principle, the more the number of constraining parts 207 arranged in the limit sleeve 206 along the circumferential direction, the smaller the rotation angle of the spool 304 under the action of a single pulse electric signal, and the higher the precision. However, in practice, due to processing Due to the accuracy and the dimensional parameters of the spacer sleeve 206, the number of the constraining parts 207 cannot be too large. For this reaso...

Embodiment 3

[0088] Since in the existing solenoid valve, whether the electromagnet and the armature 104 act (or engage) cannot be judged from the outside of the housing 101, so in the solenoid valve provided in this embodiment, the pushing part 210 (such as extending Rod 214) is also provided with state detection contact 601, as Figure 10 As shown, it can be preferentially arranged on the side of the extension rod 214. The housing 101 is provided with a fixed contact 602. 603 connected, the detection terminal 603 can be used to connect controllers, such as single-chip microcomputers, PLCs, etc.; 601 is in contact with the fixed contact 602. At this time, the state detection circuit is connected, and the controller can receive the corresponding signal through the detection terminal 603, indicating that the electromagnet and the armature 104 in the solenoid valve have been activated, so that the internal Whether or not the electromagnet and the armature 104 act (or engage) cannot be judge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com