Pantograph abrasion measuring method and system based on 3D imaging

A measurement method and pantograph technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problem of inability to realize rapid and automatic detection of pantograph wear, limited accuracy of wear calculation, and difficulty in extracting fine three-dimensional information of pantographs, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

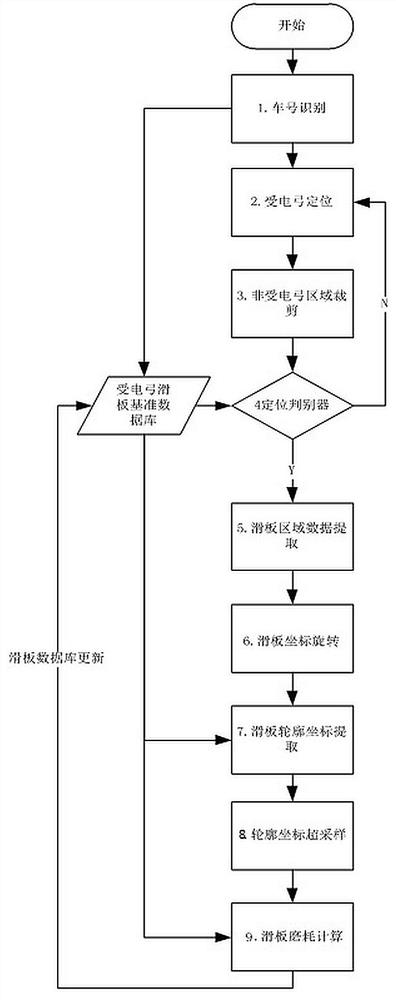

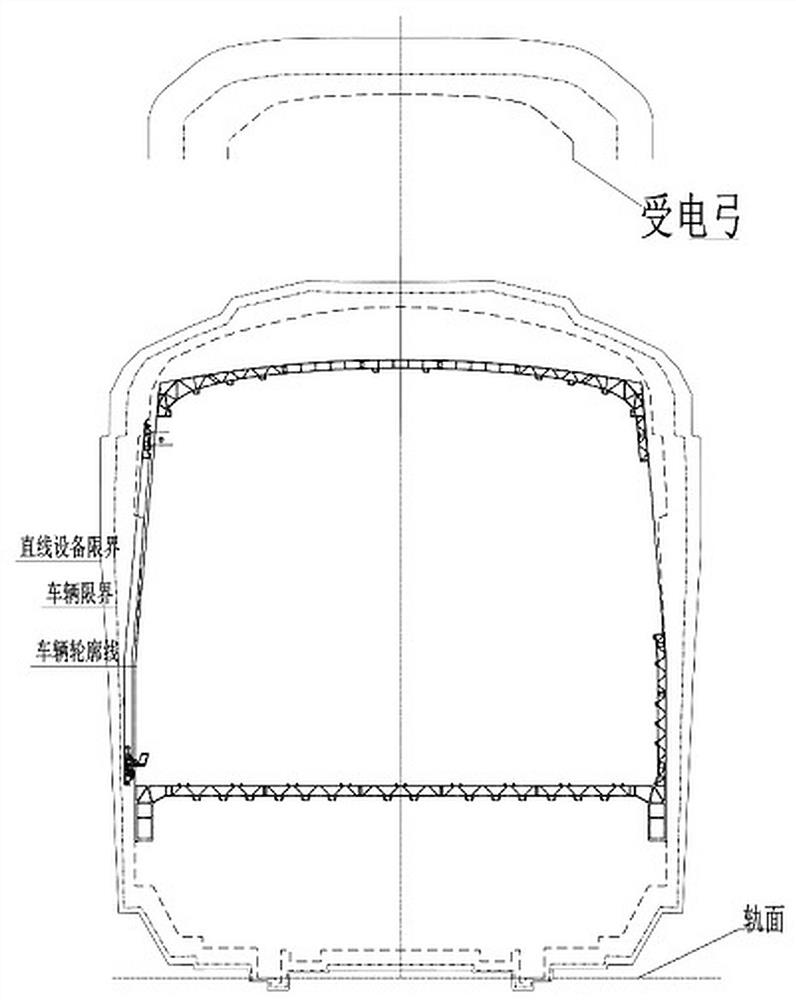

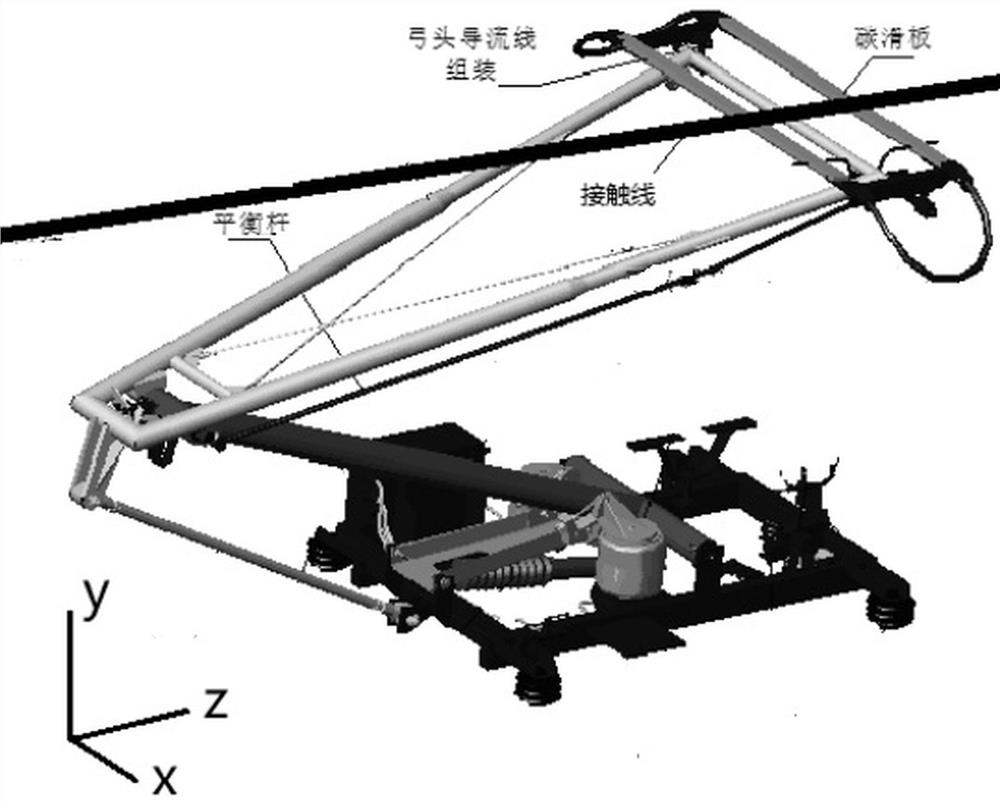

[0074] This embodiment discloses a method for measuring pantograph wear based on 3D imaging, such as figure 2 and 3 , in the imaging data based on the high-speed 3D imaging device, the pantograph and the catenary are discretized into three-dimensional data points containing three coordinates of X, Y, and Z. The original image is a grayscale image, which can be converted into a 2D edge profile. Or rendered as a three-dimensional image. In this scheme, one 3D imaging device captures half of the pantograph axis-symmetric line as the center, and the other 3D imaging device captures the other half of the pantograph, and the method of use is the same. Therefore, in this scheme The methods involved all take one 3D imaging unit as an example. During the long-term operation of the subway line, the pantograph skateboard will inevitably experience normal or abnormal wear, which is manifested in the imaging data as the subtraction of the y-coordinate value of the skateboard outline. Wh...

Embodiment 2

[0119] Further, corresponding to the wear measurement method in the above-mentioned embodiment 1, this embodiment also provides a pantograph wear measurement system based on 3D imaging, including:

[0120] The car number acquisition unit is set at the trackside and is used to acquire the car number image of the vehicle to be checked;

[0121] A reference profile acquisition unit, configured to identify the vehicle number image on the vehicle number image by using the OCR method, obtain the vehicle number of the vehicle to be detected, and retrieve the vehicle number corresponding to the vehicle to be detected in the pantograph slide reference database according to the vehicle number. datum profile history set;

[0122] The 3D imaging acquisition unit includes 2 3D imaging devices, the 2 3D imaging devices are located on the same vertical calibration plane and arranged along the horizontal direction, and are used to obtain the 3D point cloud data of the vehicle to be detected; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com