Visual management method for mechanical equipment and enterprise asset management method

A technology of mechanical equipment and management methods, applied in the directions of image data processing, electrical digital data processing, special data processing applications, etc., can solve the problems of no breakthrough development of terminal equipment management technology, inconvenient use of management methods, etc., to improve management efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

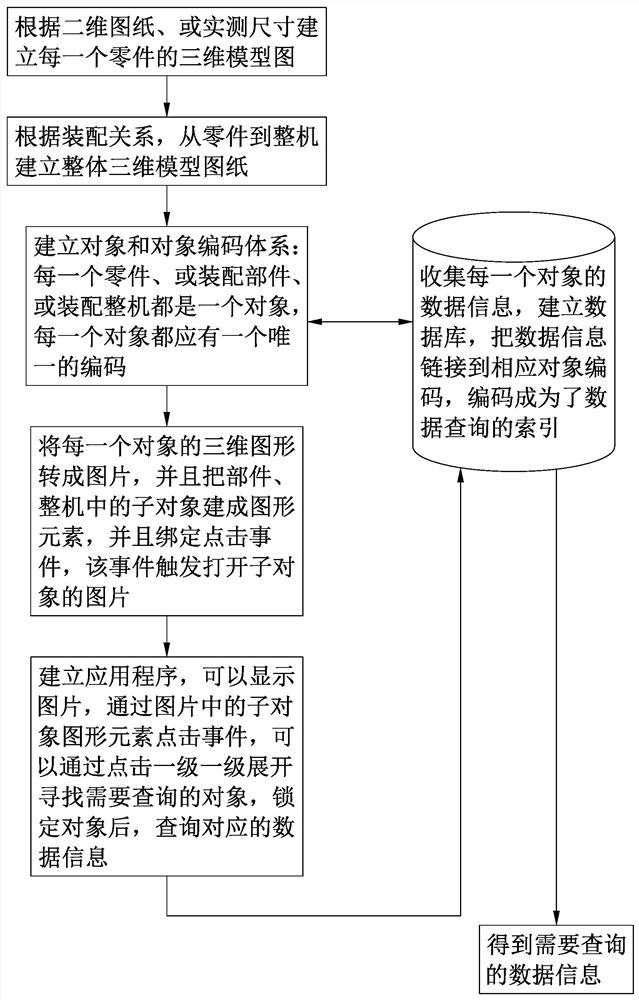

[0024] Such as figure 1 As shown, the present invention discloses a visual management method of mechanical equipment, which includes the following steps:

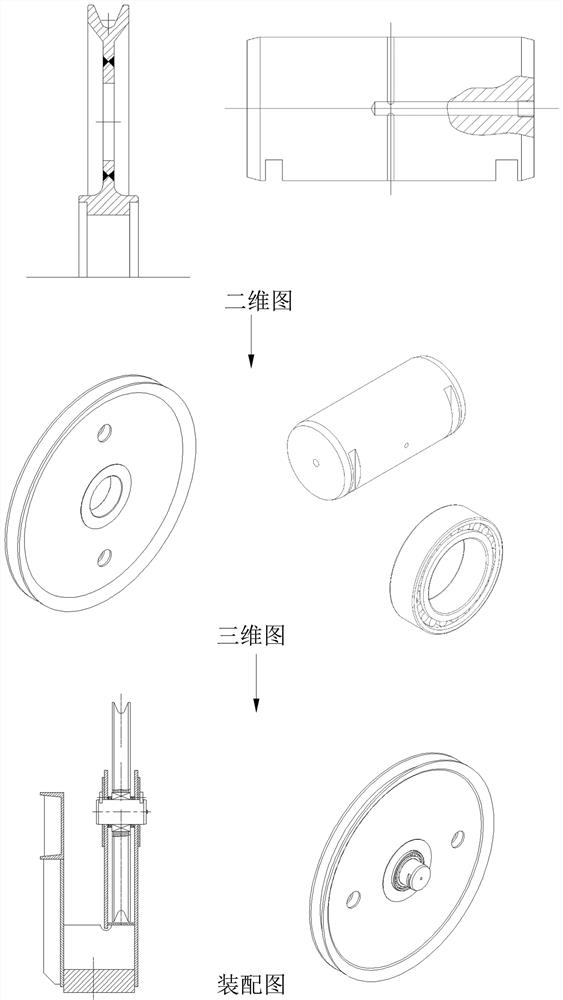

[0025] Step 1, such as figure 2 As shown, according to the two-dimensional drawings or measured dimensions of the mechanical equipment, construct the three-dimensional model diagram of each part in the mechanical equipment; then, according to the assembly relationship, construct the assembly, component, component, assembly and whole 3D model of the machine.

[0026] Step 2. Establish the object and object coding system: take each part, assembly, assembly, component and complete machine of the mechanical equipment as an object, and assign a unique code to each object, that is, the object code.

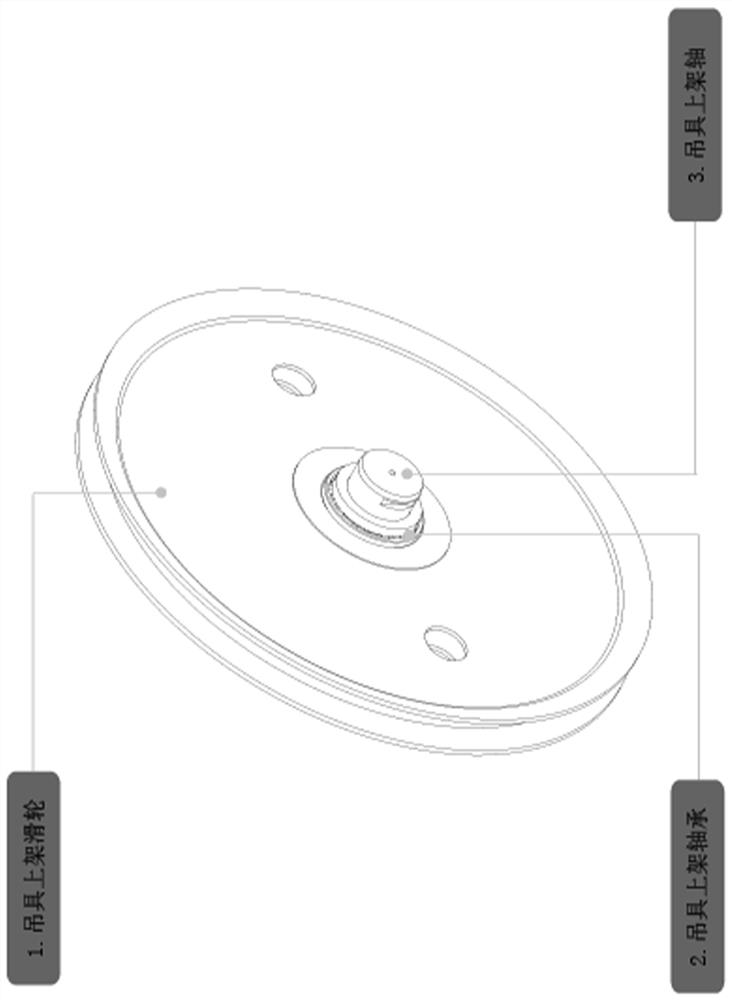

[0027] Step 3, if image 3 As shown, the 3D model diagram of each object is converted into an SVG diagram, and the sub-objects in the assembly, component, part, and whole machine are built into graphic elements, and a click event...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap