High Voltage Generator Based on MOS Tube Series Discharge

A high-voltage generator and MOS tube technology, which is applied to the parts, instruments, and measuring electronics of electrical measuring instruments, can solve the problems of reducing the output capacity of the booster and waveform distortion, so as to reduce the circuit response speed and value reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

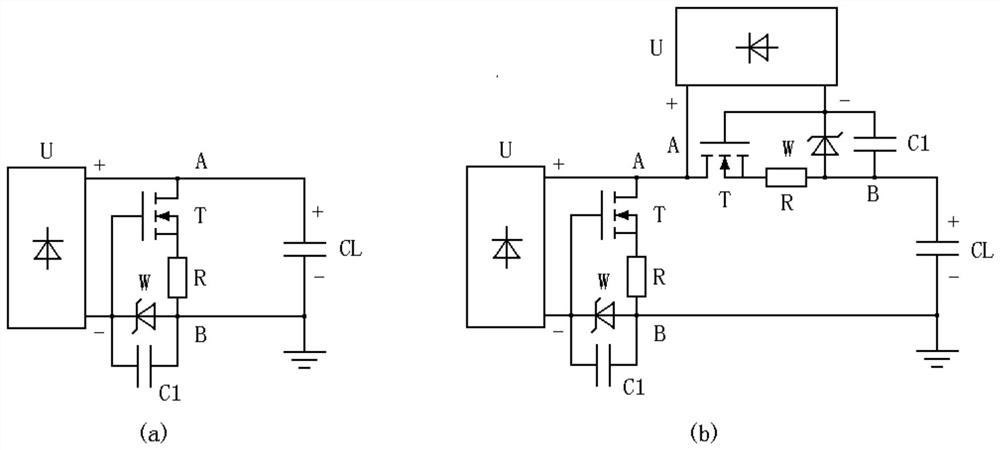

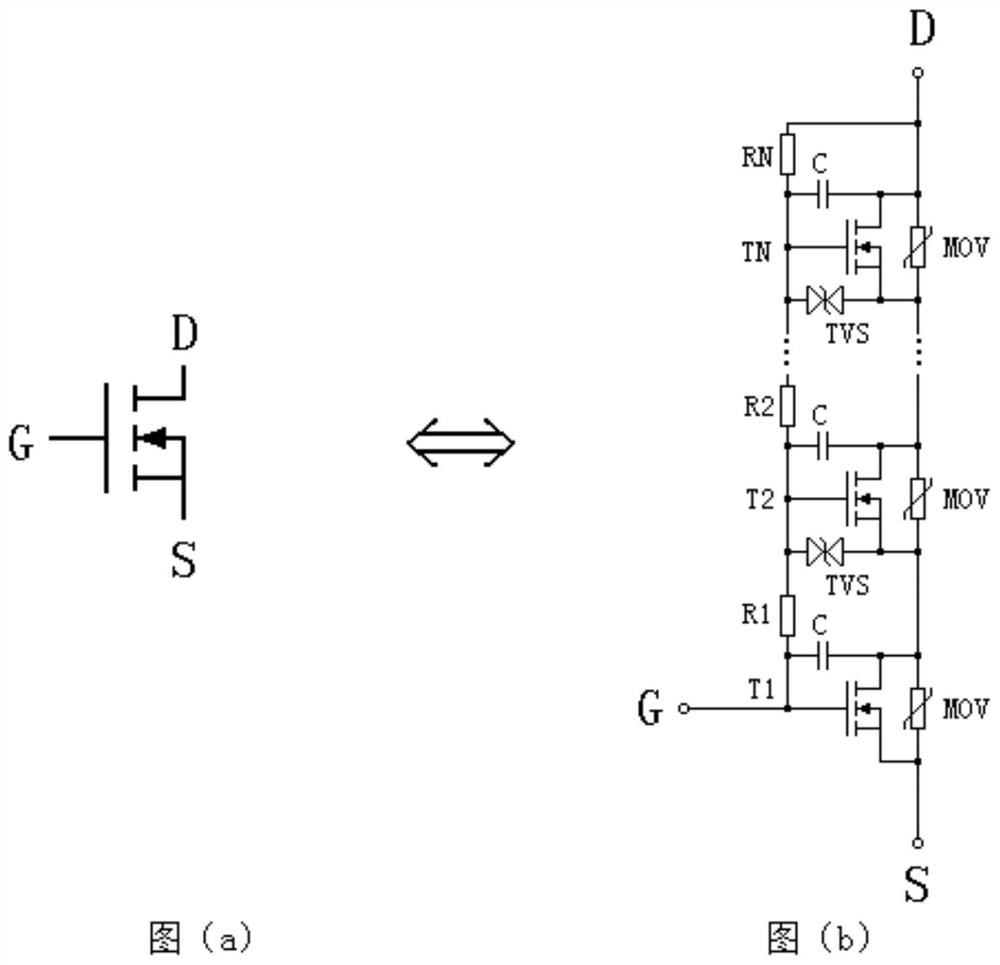

[0043] A high-voltage generator based on MOS tube series discharge, such as figure 1 As shown, it includes MOS tube series discharge circuit T, booster U, current limiting resistor R, voltage stabilizing element W and anti-interference capacitor C1, such as figure 2As shown in (b), the MOS tube series discharge circuit T includes N voltage equalizing resistors and N series connected MOS tubes. The N MOS tubes are respectively T1, T2, ..., TN, and the N voltage equalizing resistors are respectively R1 , R2, ..., RN, in the above N MOS transistors, the source of Ti is electrically connected to the drain of Ti+1, the gate of Ti is electrically connected to the first end of Ri, and the second end of Ri is electrically connected to Ti+1 The gate of 1 is electrically connected, the gate of TN is electrically connected to the first end of RN, the second end of RN is electrically connected to the source of TN, and a capacitor C is connected in parallel between the gate and source of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com