Bone screw with anti-regression and slow-release nutrient solution

A nutrient solution and bone screw technology, which is applied in the field of bone screws, can solve the problems of high screw production cost, difficult application, and loss of slow-release factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The invention will be described in detail below in conjunction with the accompanying drawings.

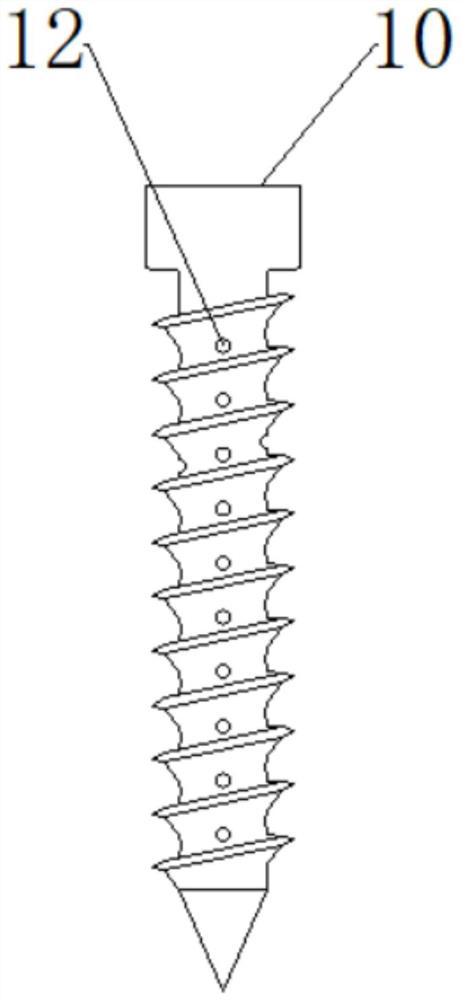

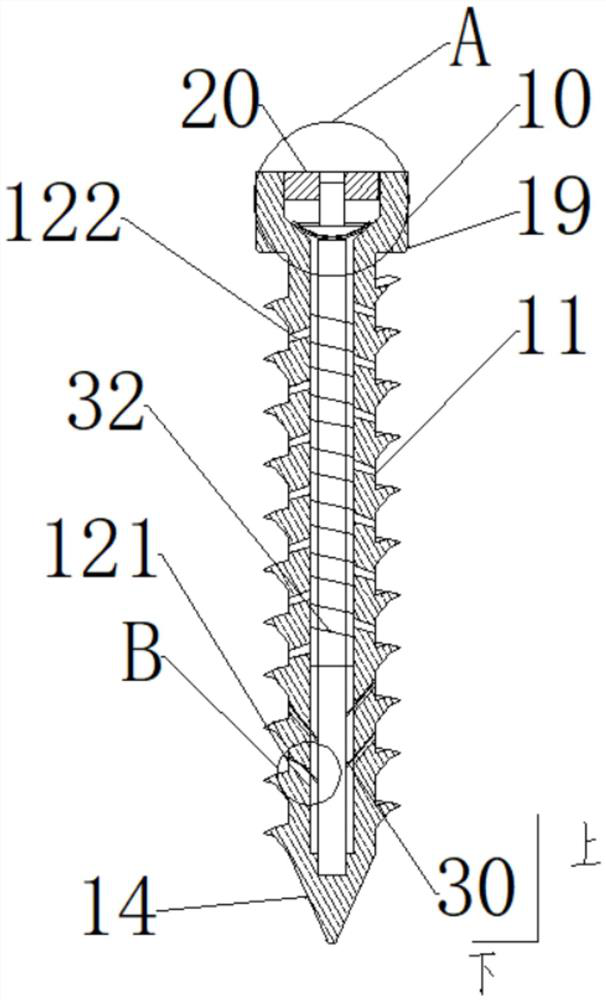

[0035] like Figures 1 to 9 As shown, a bone screw for anti-back and slow-release nutrient solution includes a main body 10, the main body 10 includes a nut head 19 and a screw rod 11, the nut head 19 and the screw rod 11 are coaxial, the nut head 19 is fixedly connected to one end of the screw rod 11, and the screw rod 11 One end away from the nut head 19 has a conical head 14, which is characterized in that:

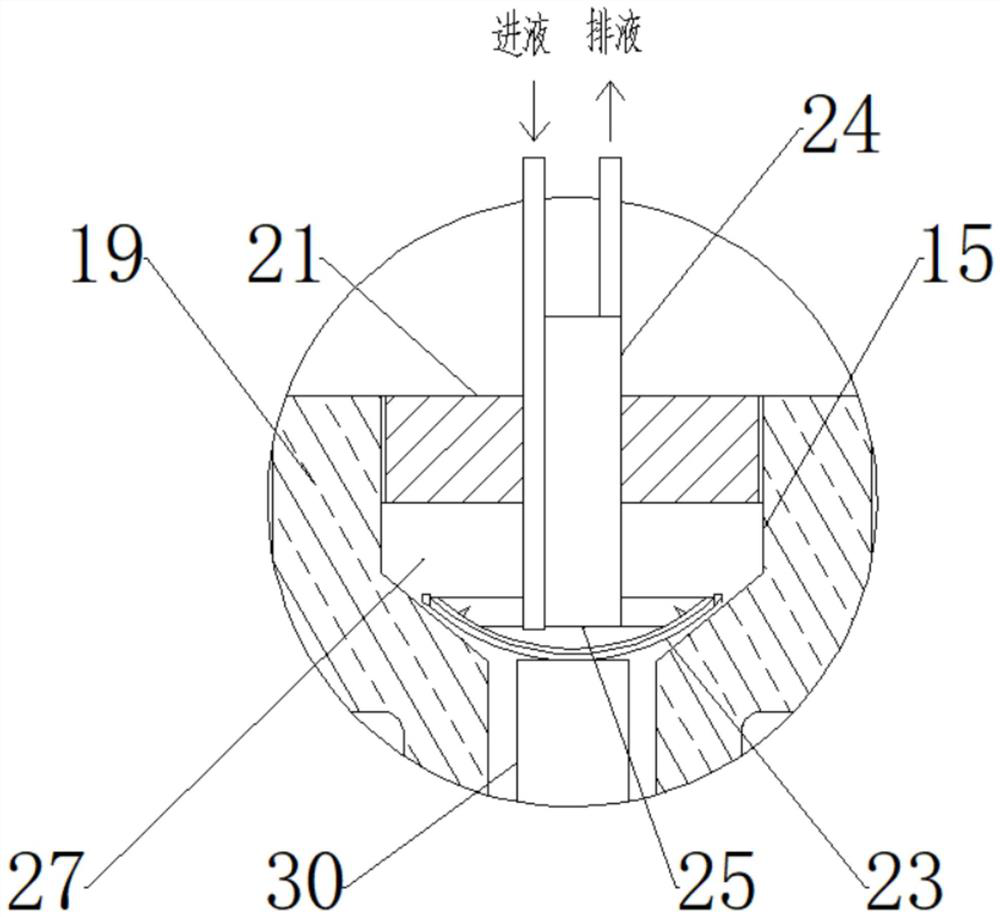

[0036] Described nut head 19 has a coaxial inner hole 15, and inner hole 15 is far away from one end opening of screw rod 11, and has coaxial blind hole 18 in described screw rod 11 with inner hole 15, and blind hole 18 is adjacent to nut head One end of 19 is open and communicates with the inner hole 15;

[0037] An inner rod 30 is inserted into the blind hole 18, and a plurality of fixed pins 31 are fixed on the inner rod 30. The plane where the axes of the fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com