Exoskeleton leg length adjusting mechanism

A technology of length adjustment and exoskeleton, which is applied in the field of rehabilitation robots, can solve the problems that the length of the patient's legs cannot be fully adapted, and the stepless adjustment mechanism cannot be completely locked, so as to achieve simple and convenient maintenance and replacement of parts, and a simple structure , Push-pull operation is easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

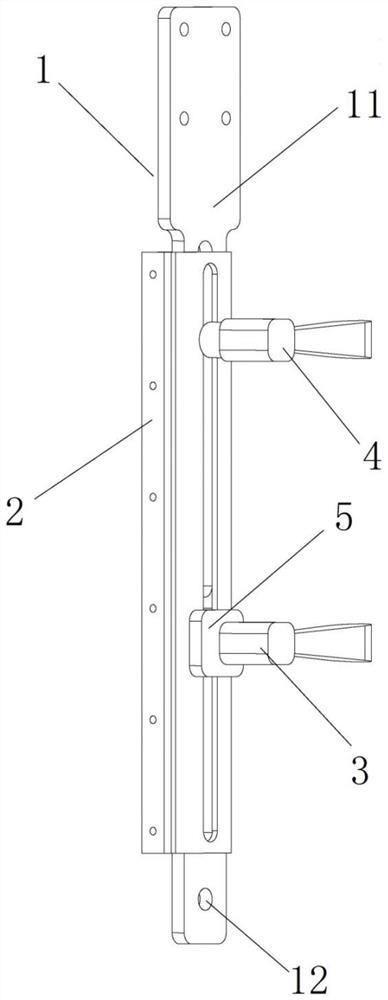

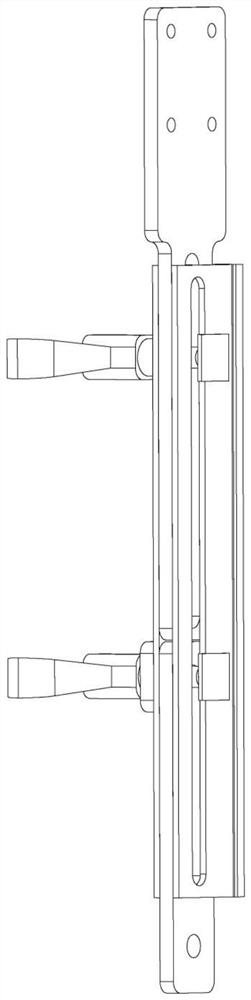

[0019] see Figure 1-2 , the present embodiment provides an exoskeleton leg length adjustment mechanism, including a thigh rod 1, the thigh rod 1 has a rectangular cross-section, and the thigh rod 1 is divided into two parts: an upper thigh rod 11 and a lower thigh rod 12. The thigh bar 11 is connected with the lower thigh bar 12 through a U-shaped sleeve 2, specifically the upper thigh bar 11, the lower thigh bar 12 and the U-shaped sleeve 2 are all provided with a strip notch, and the lower thigh bar 12 is nested into the U-shaped sleeve 2, and the long notch on the lower thigh bar 12 cooperates with the long notch on the U-shaped sleeve 2 to connect through the first push-pull quick clamp 3, that is The first push-pull quick clamp 3 connects the lower thigh rod 12 and the U-shaped sleeve 2 through the elongated notch on the lower thigh rod 12 and the U-shaped sleeve 2; the upper thigh rod 11 is nested Put it into the U-shaped sleeve 2, and the long notch on the upper thigh...

Embodiment 2

[0021] The exoskeleton leg length adjustment mechanism provided in this embodiment has the same general structure as that of Embodiment 1, the difference is that a spacer 5 is added to the first push-pull quick clamp 3 and the second push-pull quick clamp 4, Such as figure 1 shown for increased clamping force.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com