Quick stamping device for automobile part machining and using method thereof

A technology of stamping device and auto parts, applied in the field of auto parts processing, can solve the problems of workpiece processing failure, no warning device, non-standard molding workpiece, etc., to achieve the effect of ensuring processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

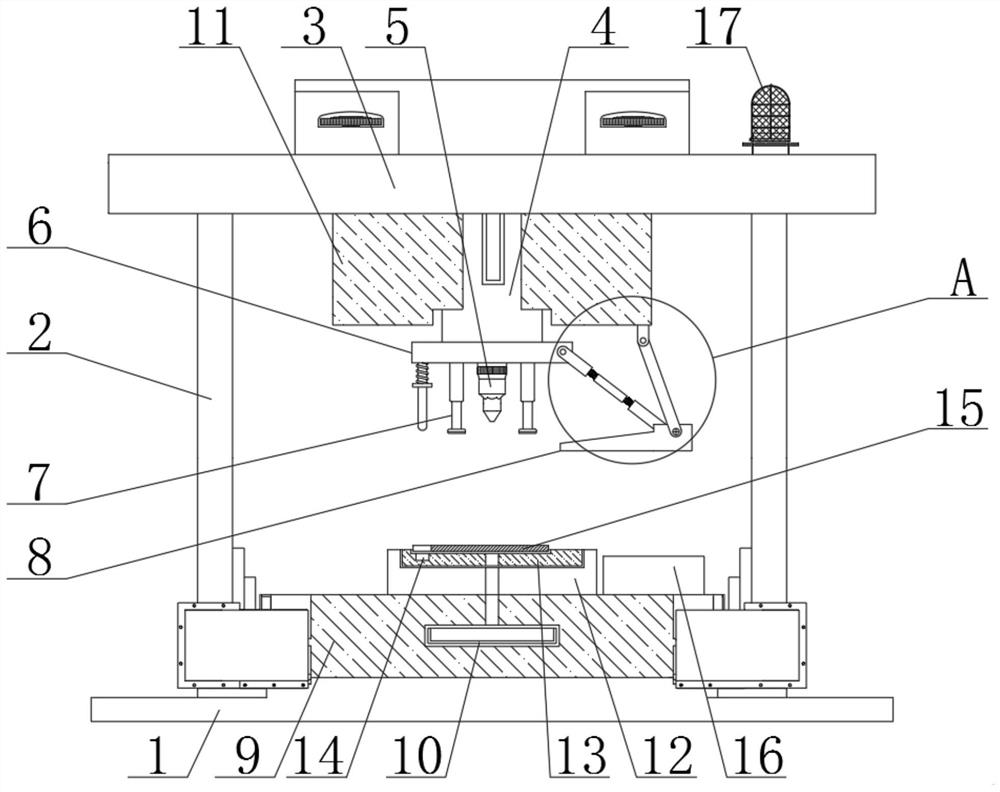

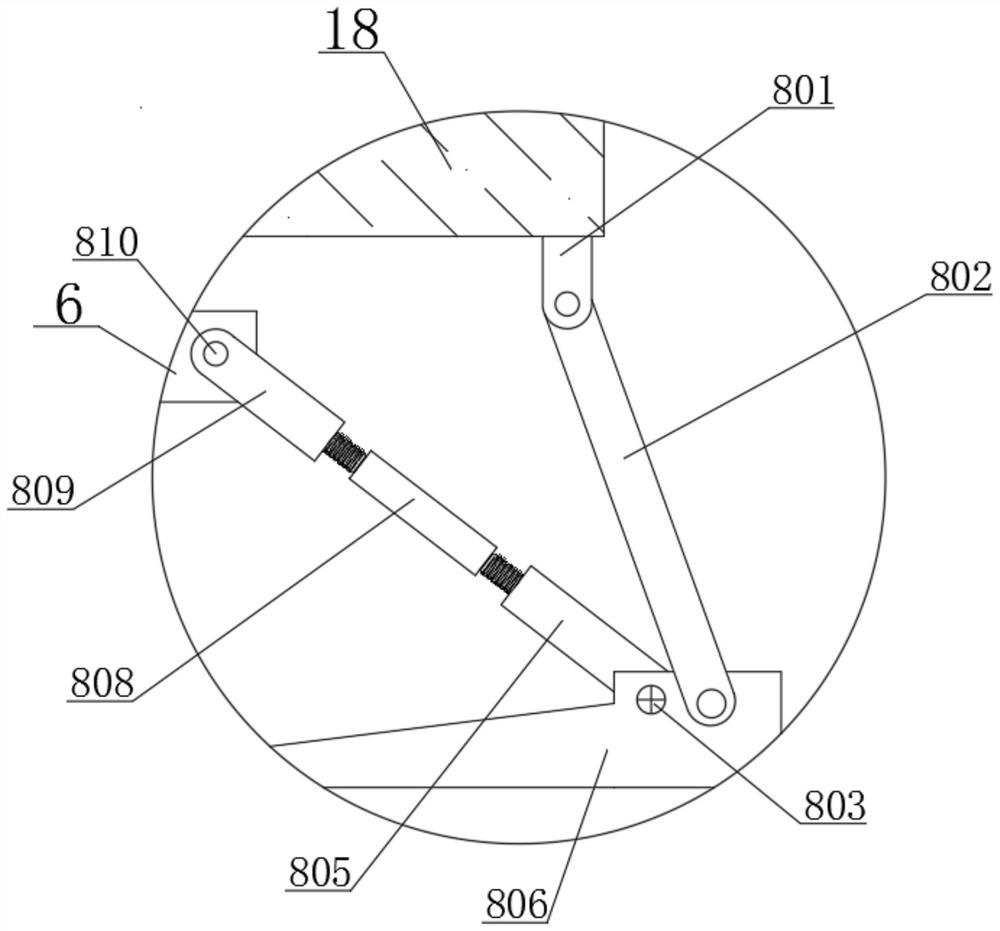

[0031] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 , the present invention provides a technical solution:

[0032]A rapid stamping device for processing auto parts and its use method, comprising a base 1 and a support rod 2, the upper end of the base 1 is fixedly connected with a workbench 9, the left and right sides of the workbench 9 are fixedly connected with a support rod 2, and the support rod 2. The upper end faces are all fixedly connected with a top plate 3, and the right side of the upper end face of the top plate 3 is fixedly connected with an alarm lamp 17. The setting of the alarm lamp 17 ensures that when the start button 602 is activated, the alarm lamp 17 plays a role in reminding, and the lower end face of the top plate 3 The center is fixedly connected with a stamping device 4, and the outer side of the stamping device 4 is slidingly connected with a protective frame 11, the upper end surface of the protective frame 11 is fix...

Embodiment 2

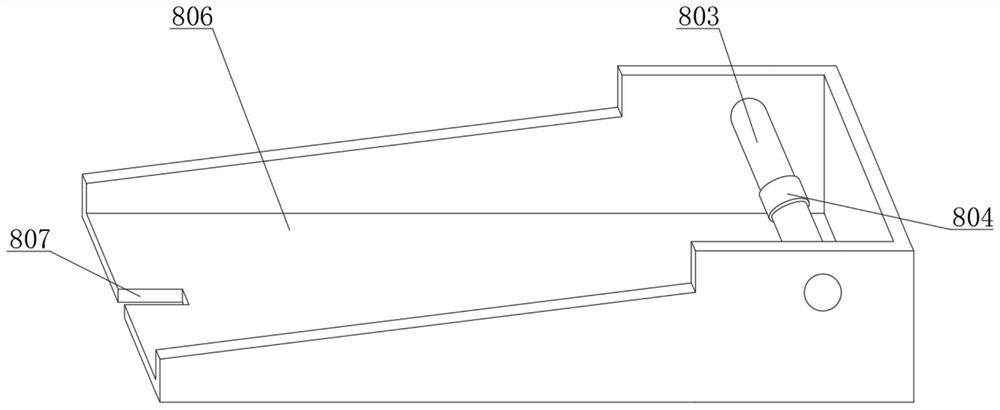

[0040] In embodiment 2, the same part as embodiment 1 will not be repeated, the difference is that when the workpiece 15 is placed in the mold frame 13, when a misalignment occurs, the workpiece 15 and the limiting groove 14 are misaligned at this time, and the guide The rod 604 is in contact with the workpiece 15, and then the guide rod 604 moves upwards to drive the fixed ring 606 to squeeze the telescopic spring 605, and then the guide rod 604 continues to drive the pressing plate 603 to slide upwards, thereby contacting the start button 602, and the start button 602 acts to make the stamping equipment 4 Stop working, and then the alarm lamp 17 lights up to remind people to carry out maintenance work, avoiding the situation of wrong processing, and can drive the upper unit threaded sleeve 809 and the lower unit threaded sleeve 805 to move by rotating the threaded rod 808, thereby can be adjusted according to the actual situation The position of the shovel frame 806 is conven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com