Die-adjustable workpiece forging press

A technology for forging presses and workpieces, which is applied in the field of workpiece forging presses, can solve problems such as deformation of the workbench and lower precision of forging blanks, and achieve the effects of increasing service life and improving forging precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

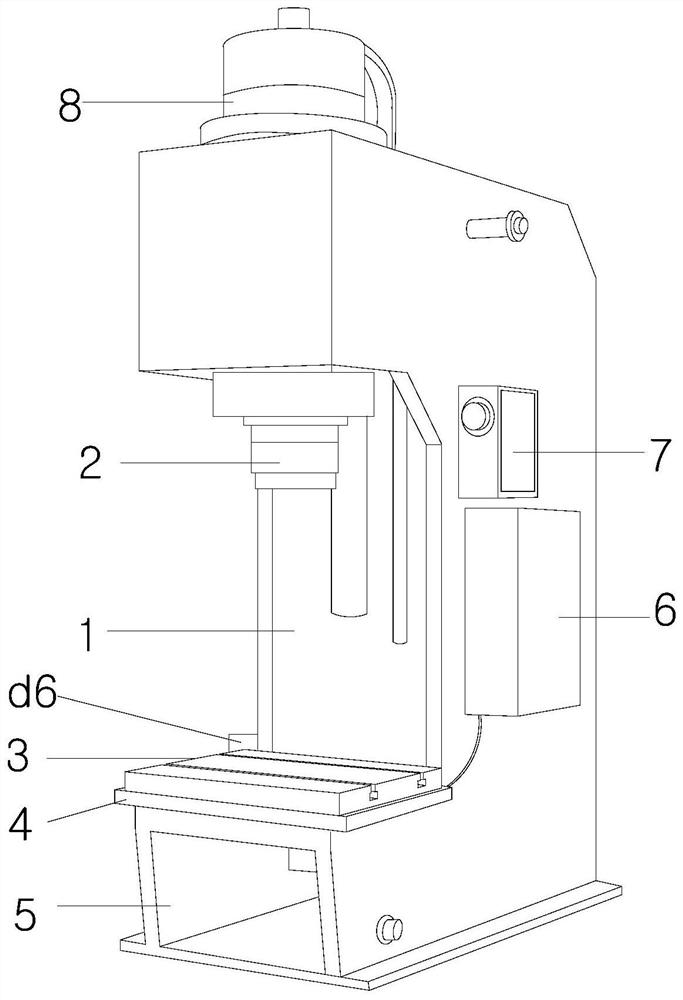

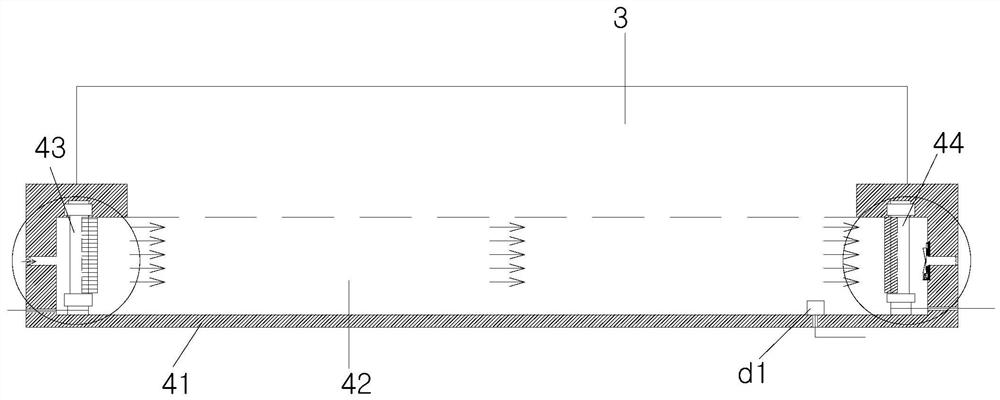

[0030] see Figure 1-Figure 4 , a workpiece forging press with adjustable molds, the present invention provides a workpiece forging press with adjustable molds, the structure of which includes a forging press host 1, a forging head 2, a workbench 3, an accurate offset measuring mechanism 4, and a load-bearing base 5 , a power supply box 6, a central control processing box 7, and a forging pressing mechanism 8, the forging pressing mechanism 8 is arranged above the main body 1 of the forging press, and one end of the lower part of the forging pressing mechanism 8 passes through the main body 1 of the forging press and the forging press The head 2 is connected, the precise offset measurement mechanism 4 is connected under the workbench 3, the bottom end of the precise offset measurement mechanism 4 is screwed to the load-bearing base 5 through a nut, the power supply box 6 and the central control processing box 7 Tighten it on the right side surface of the forging machine host 1...

Embodiment 2

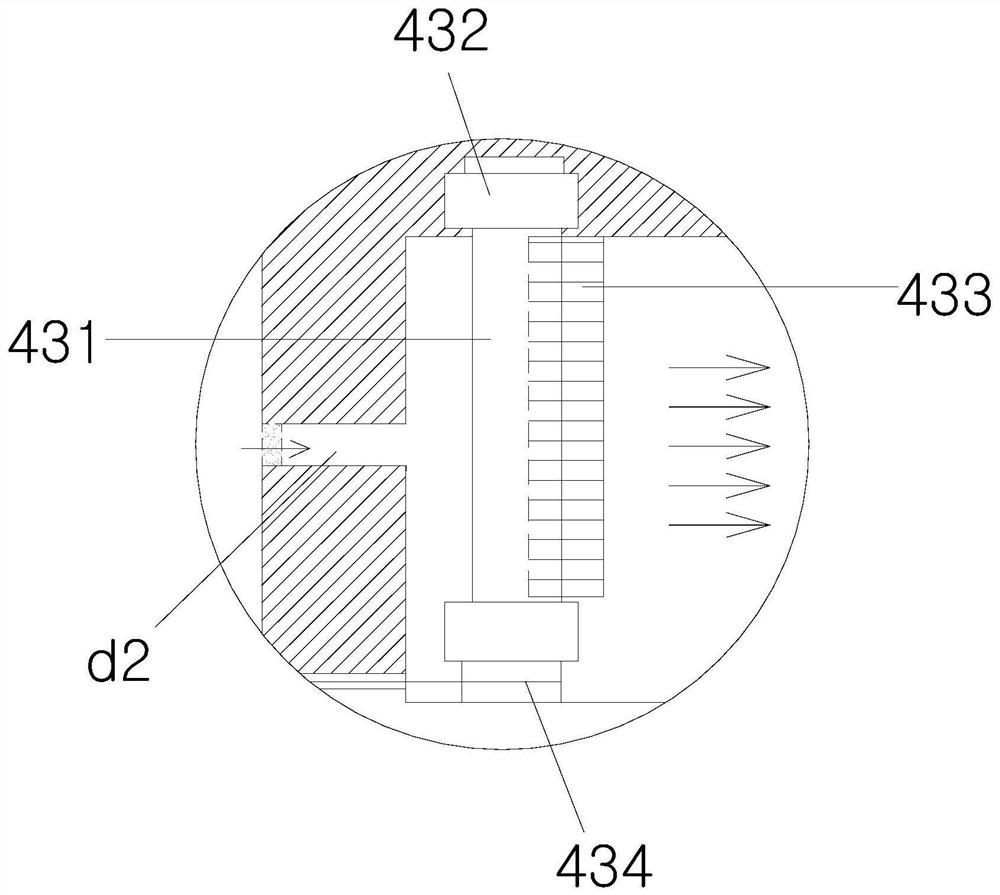

[0036] see Figure 4-Figure 8 , a workpiece forging press with adjustable molds, the present invention provides a workpiece forging press with adjustable molds, the structure of which includes the dry protection system 44d, the dry protection system 44d consists of a humidity sensor d1, an air inlet d2 , an upper closing assembly d3, a lower closing assembly d4, a rubber sealing plate d5, a dry air pump d6, and an air outlet d7. The humidity sensitive element d1 is arranged in the inner cavity 42 and is arranged in the lower left corner of the infrared receiving plate 44b. The air inlet d2 is located on the left side of the inner cavity 42, the upper closing component d3 and the lower closing component d4 are connected to the inner wall on the right side of the inner cavity 42, and the air outlet d7 is connected through the right side of the inner cavity 42. The above-mentioned glue sealing plate d5 is embedded and connected in the air outlet d7, and is tightly bonded by an ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com