Tool for clamping large Venturi tube free forging blank vertical lathe

A Venturi tube and blank technology, applied in clamping, positioning devices, manufacturing tools, etc., can solve the problems of increasing the cutting time of pulling fur, prolonging the number of passes, affecting product quality, etc. Efficiency, improved stability and reliability, the effect of saving setup adjustment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

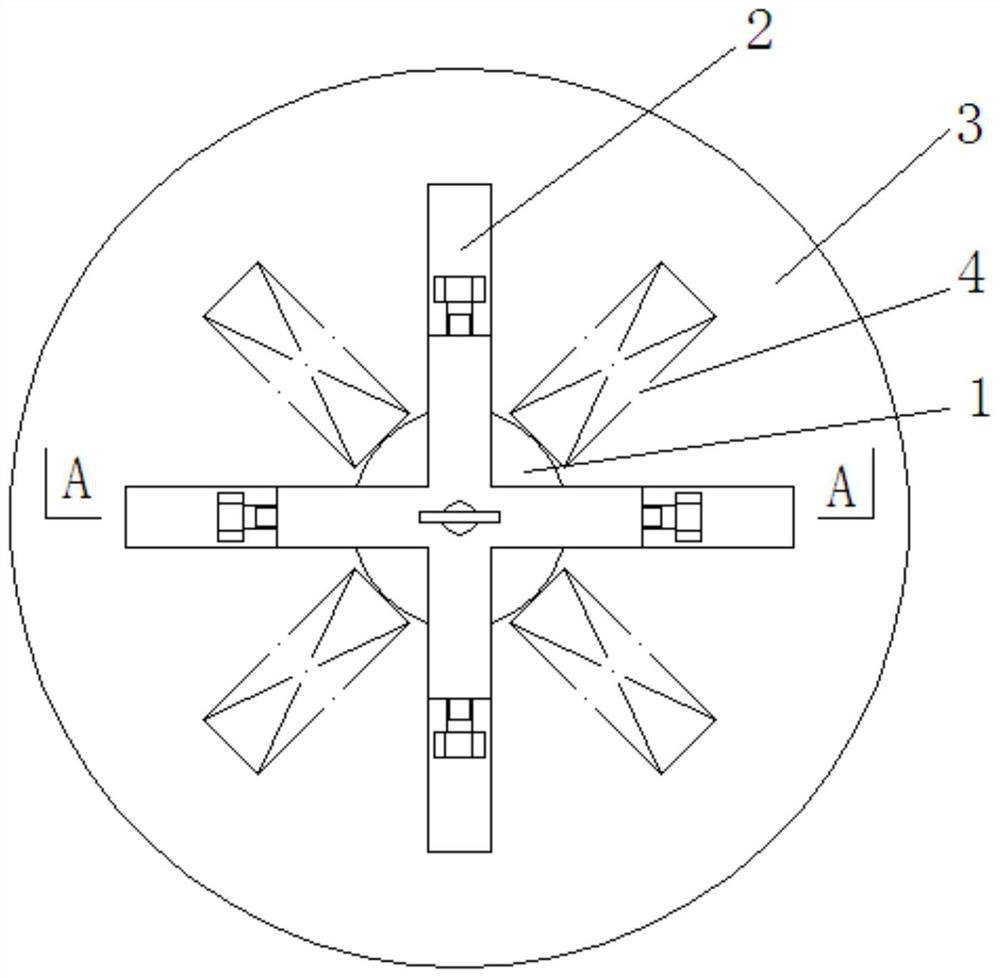

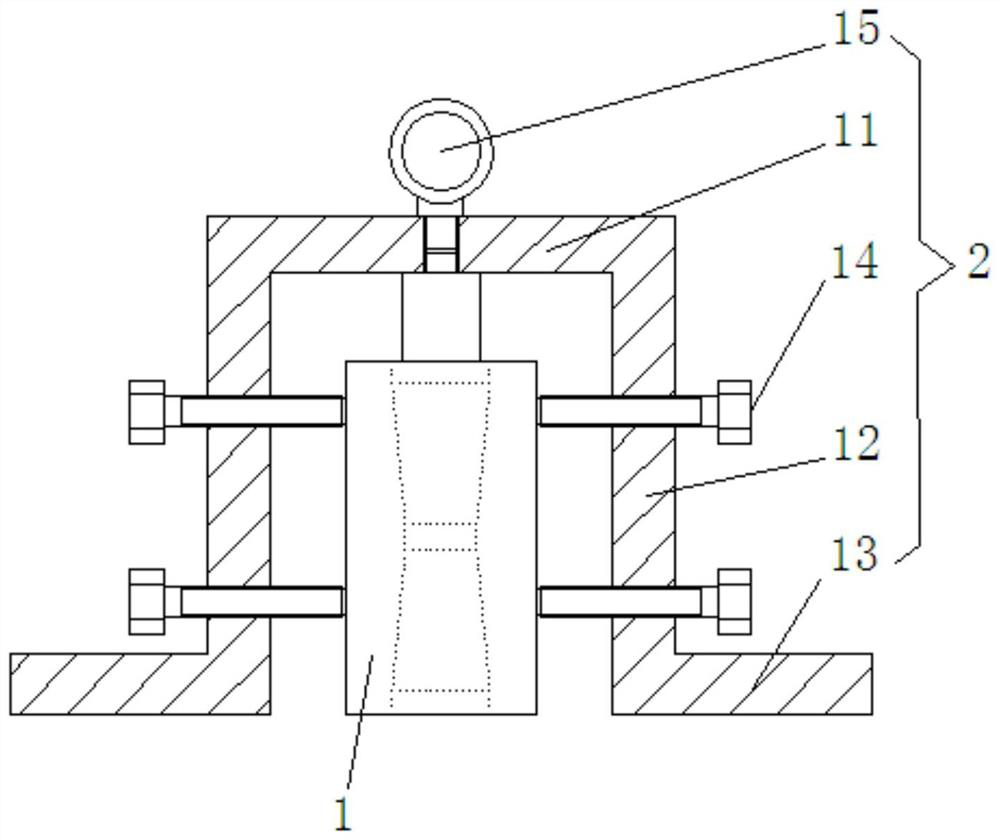

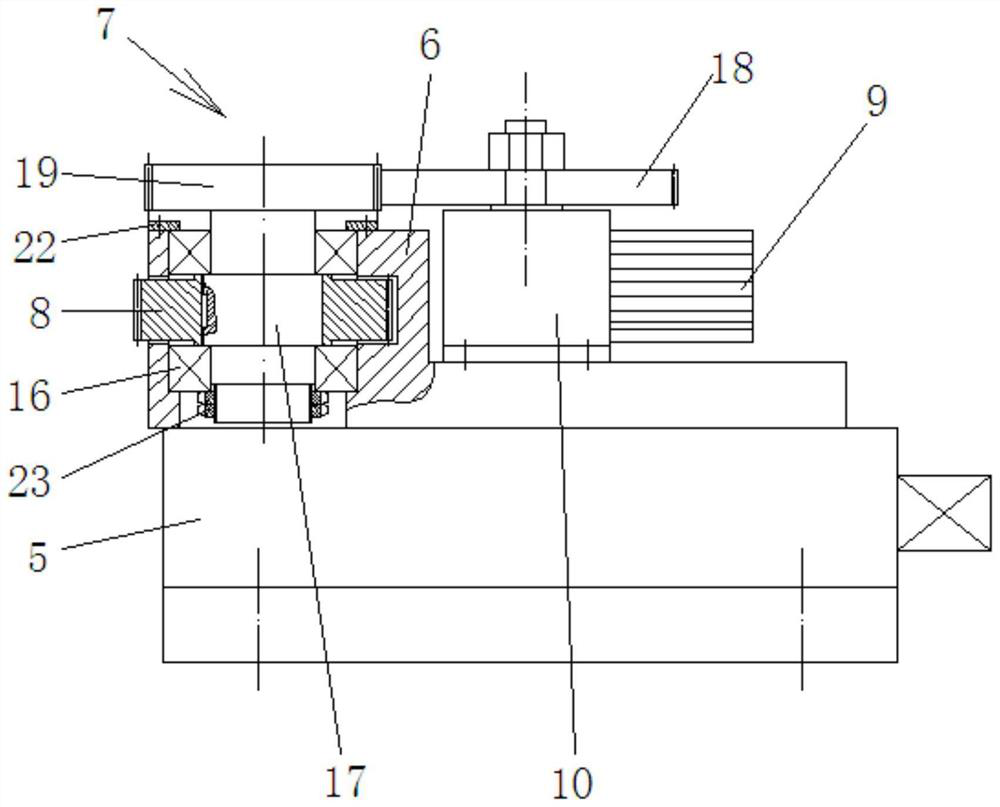

[0033] Such as Figures 1 to 4 Shown is an embodiment of a tooling for vertical lathe clamping of a large Venturi tube free forging blank of the present invention, including a hoisting schedule for hoisting the Venturi tube forging blank 1 and pre-positioning it on the vertical lathe workbench 3 Position fixture 2, vertical lathe claw 4 installed on the vertical lathe workbench 3 for clamping the outer circle of the Venturi tube free forging blank 1, the vertical lathe claw 4 includes a vertical lathe jaw 4 for connecting the vertical lathe The claw seat 5 of the table 3, the movable and clamped claw body 6 arranged on the claw seat 5, the front end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com