Floating support applied to grinding machine

A floating bearing and grinding machine technology, used in the field of bearing processing, can solve the problems of surface roughness not meeting requirements, process requirements, and unqualified products. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] For the convenience of description, the direction extending along the axial direction of the part 4 to be processed is now defined as the front-rear direction.

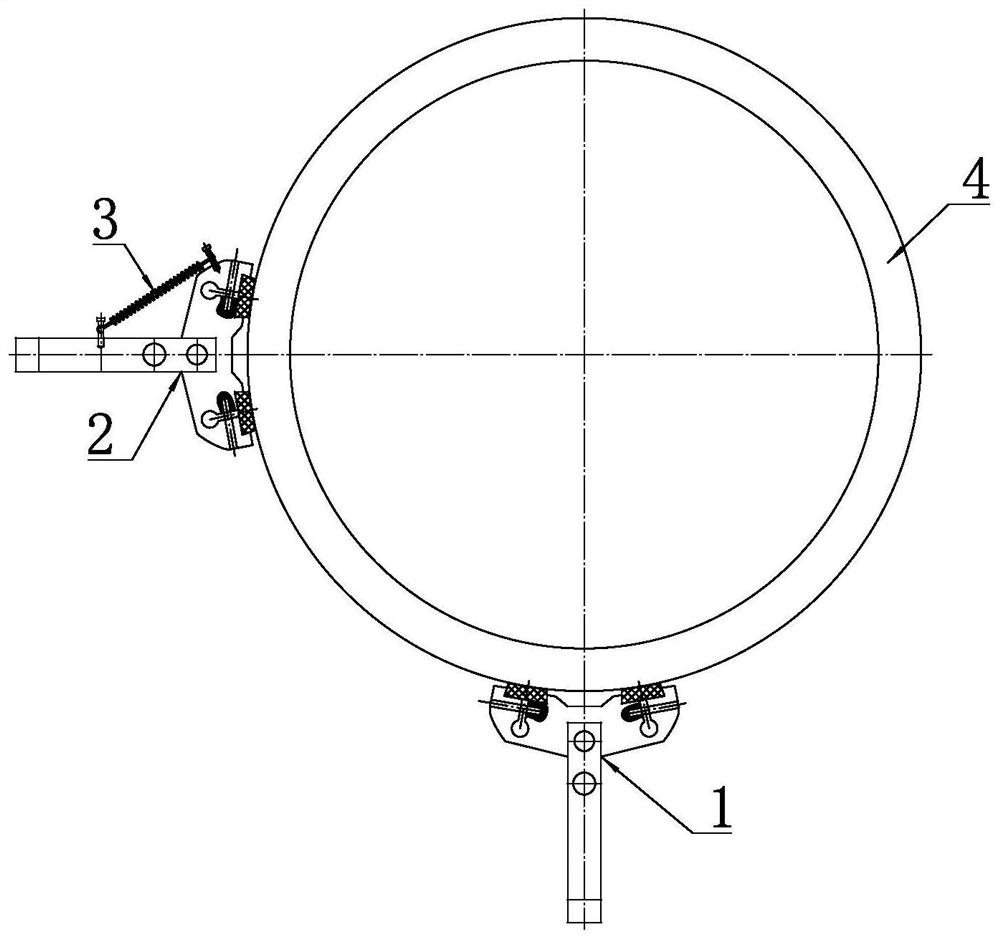

[0043] Such as figure 1 As shown, a floating bearing applied to a grinding machine includes a first support assembly 1 and a second support assembly 2, wherein the first support assembly 1 is located on the underside of the part 4 to be processed, and the second support assembly 2 It is located on the left or right side of the part 4 to be processed, and the first support assembly 1 and the second support assembly 2 have the same structure. As a specific implementation, the second support assembly 2 described in this embodiment is arranged on the left side of the part 4 to be processed.

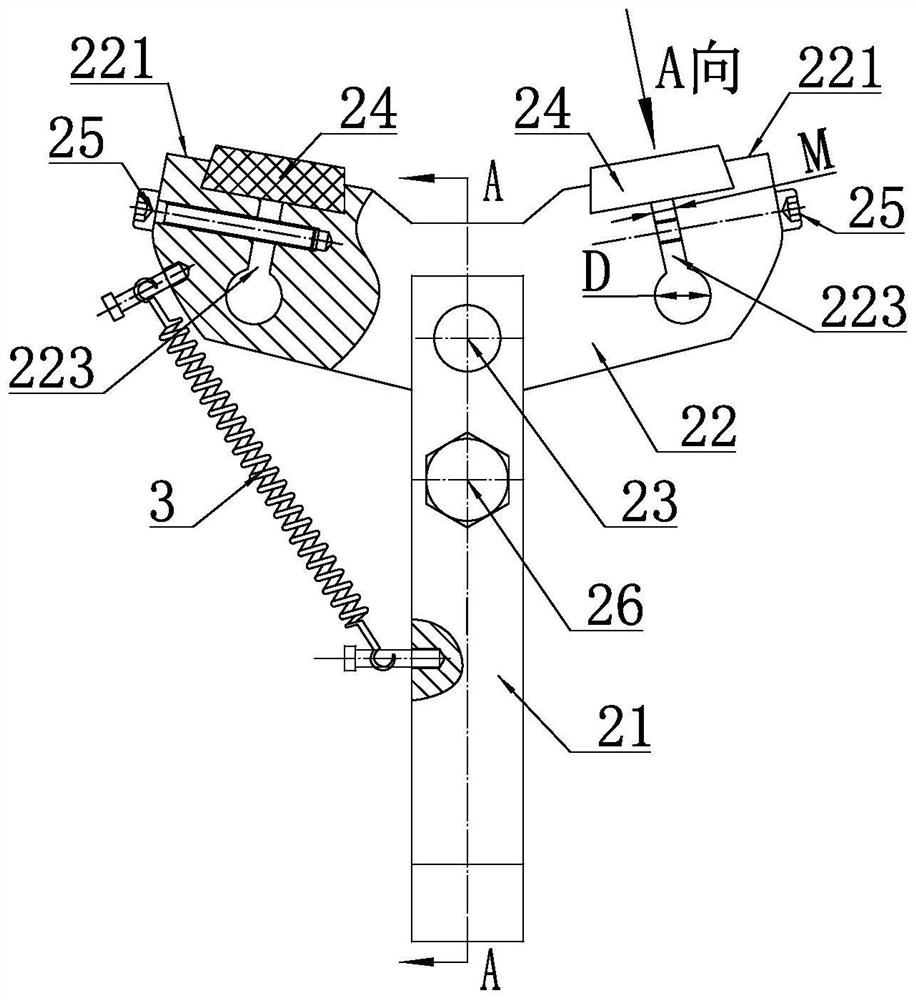

[0044] Here, only the second support assembly 2 is taken as an example to describe its structure in detail.

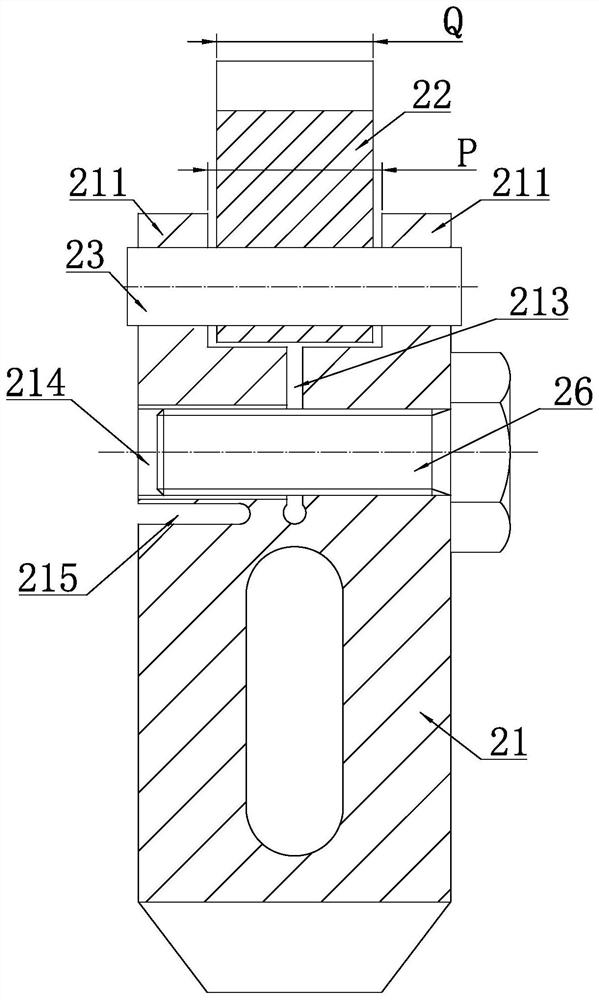

[0045] Such as figure 2 As shown, the second support assembly 2 includes a support rod 21 and a support head 22...

Embodiment 2

[0061] The first expansion joint 223 runs through the support head 22 in a direction perpendicular to the bottom surface of the clamping groove 222, that is, the body of the support head 22 is a separate structure from the clamping part, so Two first locking bolts 25 are arranged between the aforementioned clamping portion and the main body of the support head 22 . All the other structures are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com